Furniture-Grade Eco Plywood System

|

Main Production Equipment in the line

A complete continuous production line for furniture-grade eco-friendly plywood primarily includes the following core equipment:

1. Log Processing Line: Includes log saw, debarker, hot water bath, etc.

debarker

cutting saw

2. Veneer Lathe (Peeler): The core equipment that peels logs into continuous veneer.

veneer lathe

veneer peeling machine

3. Veneer Dryer: Typically roller or mesh belt type, for precise control of veneer moisture content.

veneer dryer

veneer dring machine

4. Formaldehyde-Free Glue Mixing & Application System: A key part of the eco-friendly line, includes Formaldehyde-Free Adhesive Mixing Tanks and the Glue Spreader (can be roller or curtain coater type).

glue mixer

giue spreading machine

5. Automatic Layup Line: Manual layup tables or fully automatic layup machines.

6. Pre-Press: Usually a cold press, for initial mat shaping.

pre pressing machine

pre press

7. Hot Press: The heart of the production line; a multi-opening hot press or continuous press, providing the heat and pressure for adhesive curing.

plywood hot press

hot press

8. Cooler/Turner: Cools and turns the hot panels after pressing.

turning machine

turner

9. Panel Curing (Seasoning) Area: Designated space for panels to rest and release stress.

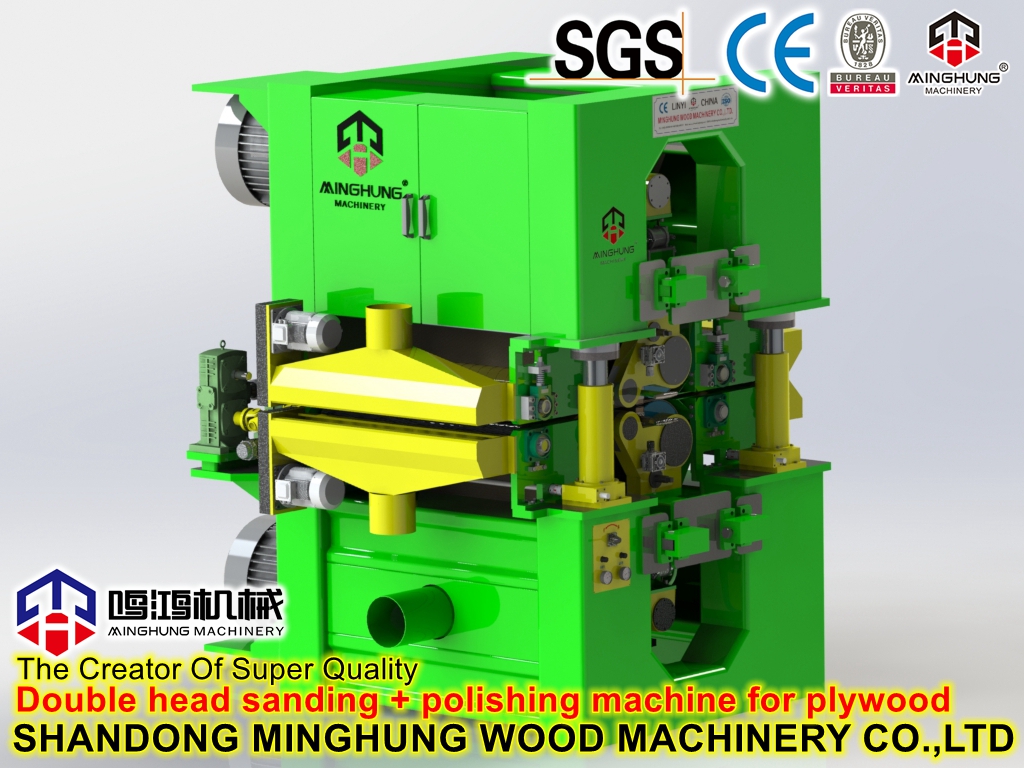

10. Calibrating Sander: Typically a wide-belt sander, for ensuring panel thickness and surface smoothness.

plywood sander

sanding machine

11. Cross-Cutting and Edge-Trimming Saws: For precise trimming of panel length and width.

edge trimming machine

cross cut saw

12. Quality Control Center: Includes inspection tables, measuring tools, and environmental testing equipment.

13. Automatic Stacking and Packaging Machine: For automated stacking and packaging of finished products.

veneer stacker for plywood

veneer stacker

The production of furniture-grade eco-friendly plywood is a process that deeply integrates "Precision Manufacturing" with "Green Technology." The precise control at every stage, especially the application of formaldehyde-free adhesives and the strict hot-pressing and sanding processes, collectively ensures the final product meets the extreme demands of modern furniture for health, aesthetics, and durability.

|

Production Process

The production of furniture-grade eco-friendly plywood is a precise, multi-step process where each stage is crucial to the final product's environmental rating, stability, and aesthetics.

The core process is as follows:

Phase One: Raw Material Preparation & Veneer Processing

1. Log Selection & Treatment

Process: High-quality logs (e.g., Eucalyptus, Poplar, Birch) from sustainably managed forests (e.g., FSC certified) are selected. Logs are cut into specific lengths and softened in a hot water bath to facilitate peeling.

Purpose: To ensure eco-friendly sources and controlled quality of raw materials.

2. Veneer Peeling & Drying

Process: The softened log sections are rotated and peeled on a lathe into continuous, uniform thin sheets called "veneer." The wet veneer is then fed into a dryer to reduce and precisely control its moisture content to a low, uniform level (typically 8%-12%).

Purpose: To create the basic building blocks of plywood. Drying is critical, as high moisture content affects glue adhesion and can cause warping later.

Phase Two: The Eco-Core - Gluing & Layup

3. Formaldehyde-Free Gluing

Process: The dried veneer sheets pass through a Glue Spreader, which applies an even coat of eco-friendly adhesive. For furniture-grade eco-friendly plywood, this involves using formaldehyde-free glues like Soy-Based Adhesive or MDI Adhesive.

Purpose: This is the core step for achieving "eco-friendly" and "formaldehyde-free" status. Using bio-based or MDI adhesives prevents the introduction of formaldehyde at the source.

4. Layup (Assembly)

Process: The glued veneers are assembled manually or automatically following the "symmetry rule" and "odd-number rule." This means the grain direction of adjacent veneers is perpendicular, ensuring balanced strength in all directions.

Purpose: To form the plywood "blank" or "mat," establishing the foundation for its structural stability.

Phase Three: Forming & Curing

5. Pre-Pressing

Process: The assembled mat is first fed into a Pre-Press for initial compaction under cold or slightly warm pressure.

Purpose: To achieve initial bonding between veneers, remove air pockets, and create a tight, handleable mat that can be transported into the hot press.

6. Hot Press Curing

Process: This is the "heart" of the production line. The pre-pressed mat enters a Hot Press subjecting it to high temperature and high pressure. Under specific temperature, pressure, and time settings, the adhesive cures rapidly, permanently bonding the multiple veneer layers into a solid panel.

Purpose: To finalize the panel form and impart the required physical and mechanical strength.

Phase Four: Post-Processing & Quality Control

7. Cooling & Curing (Seasoning)

Process: The newly pressed, hot panels are cooled by a Cooler/Turner. Afterwards, the panels are stored for a period of "curing" or "seasoning."

Purpose: To release internal stress, balance moisture content, stabilize panel performance, and prevent deformation.

8. Calibrating-Sanding & Trimming

Process: The seasoned panels first go through a Calibrating Sander for fine sanding of both surfaces, ensuring precise thickness and a perfectly smooth, flat surface. Then, Cross-Cutting and Edge-Trimming Saws trim the rough edges to achieve exact dimensions and smooth edges.

Purpose: To enhance the panel's appearance and usability, providing a perfect substrate for subsequent finishing processes like laminating or edge-banding.

9. Inspection & Packaging

Process: Finished panels undergo 100% inspection, including thickness measurement, surface defect check, and environmental grade testing (e.g., sampled with formaldehyde detectors). Qualified products are stacked and packaged by an Automatic Stacking and Packaging Machine.

Purpose: To ensure that all shipped products 100% meet the quality and environmental standards for furniture-grade plywood.

|

Comparision with traditional plywood

Feature | Furniture-Grade Eco-Friendly Plywood System | Ordinary Construction/Industrial Plywood |

Environmental Standard | A core indicator. Pursues No Added Formaldehyde (NAF) or ultra-low formaldehyde, with authoritative certifications. | Not a core indicator. Typically meets only E1 or E2 standards; may have a pungent odor. |

Raw Materials | Selected high-quality wood veneers, free of holes and overlaps. | Lower requirements for wood species and veneer quality; may contain mixed wood and have repairs. |

Production Process | Precise glue application, symmetrical layup, strictly controlled hot-pressing curves. | Relatively rough process; higher risk of bonding failure and inconsistency. |

Performance | High strength, high stability, excellent machining performance. | Average performance, prone to warping, and susceptible to chipping during machining. |

Appearance | Smooth surface, clear grain, suitable for direct veneering or painting. | Rough surface, often used as a substrate that will be covered. |

Primary Use | High-end furniture, interior decoration, children's rooms, commercial spaces. | Formwork, packing cases, partitions, and other non-exposed structures. |

|

Main application scenarios

High-End Custom Furniture: Wardrobes, bookshelves, TV cabinets, dining tables, etc.

Children & Infant Furniture: The sector with the highest requirements for environmental protection and safety.

Kitchen & Bathroom Cabinetry: Especially the moisture-resistant product series.

Hotel & Commercial Fixed Furniture: Such as wall cladding, fixed partitions, reception desks, etc.

Interior Doors & Door Frames: Ensures no warping or cracking.

Artwork or Decorative Components requiring intricate carving and laser cutting.

We can offer factory layout design, installation, operator training, 24-month warranty, and global spare parts delivery within 72 hours.

Whatsapp: +8618769900191 +8615589105786 +8618954906501

Email: osbmdfmachinery@gmail.com