|

Core Features & Advanteges

Efficient Multi-functional Processing: Integrates peeling and fixed-length cutting control, suitable for processing logs and wood cores of various diameters to maximize raw material yield.

Superior Peeling Precision: Utilizes Optimal Peeling Geometry (OPG) technology to ensure veneer with excellent thickness tolerance and a smooth surface. Peeling thickness error can be controlled within ±0.01mm.

Intelligent Automated Control: The system is controlled by a high-performance PLC and a color HMI interface. It integrates parameter setting and calculation for peel thickness and cut length, offering simple operation and a high degree of automation.

Stable & Reliable Drive: The core drive employs high-performance vector inverters or servo systems, providing excellent speed control accuracy, low-frequency torque, and fast dynamic response to ensure a stable and uniform peeling process.

|

Technical Specifications

Item | Parameter / Description |

Suitable Log Diameter | Medium Range (e.g., 100mm - 600mm, customizable) |

Max. Peeling Length | Customizable (Common range: 800mm - 2600mm) |

Peeling Thickness Range | 0.5mm - 5.0mm (adjustable) |

Thickness Accuracy | ≤ ±0.01 mm |

Cutting Length Error | ≤ ±20 mm |

Control Core | Industrial PLC, supports high-speed pulse and multi-machine communication |

Drive System | AC servo systems and high-performance inverters for coordinated drive |

Main Power Requirement | 380V, 3 Phase, 50Hz (customizable per regional standards) |

Key Functions | Spindleless peeling, automatic fixed-length cutting, online thickness fine-tuning |

|

Application Video

|

Main Component Structure

1. Mechanical Structural Components

Bed & Base: Heavy-duty steel construction ensuring overall rigidity and stability during high-speed peeling, minimizing vibration.

Headstock & Tailstock: Used to clamp and drive the log rotation. Medium-sized machines often feature a spindleless design, driven by friction rollers, allowing for secondary processing of small-diameter cores.

Carriage Assembly: The core component, housing the peeling knife, pressure bar, and fine-tuning mechanism. It executes the precise peeling motion, and its feed accuracy directly determines veneer thickness.

Transmission System: Includes the main motor, gearbox, gears, and lead screws. It transfers power to the spindle and carriage, enabling log rotation and precise carriage feed.

2. Control & Drive System

PLC Control System: The "brain" of the machine. Receives operator commands and sensor signals, precisely coordinates carriage feed speed with spindle rotation, and controls automatic cutting.

Servo/Inverter Drive System: The "muscles" of the machine. Provides high-precision, variable-speed power for the carriage feed and spindle rotation, which is key to achieving stable peeling and energy efficiency.

Human-Machine Interface (HMI): A color touchscreen, serving as the primary interface for operators to set parameters (thickness, length), monitor status, and diagnose faults.

Sensor System: Includes encoders (measuring speed and position), proximity switches, etc., providing real-time feedback on machine status to form a closed-loop control.

3. Auxiliary Functional Components

Automatic Cutting Device: Integrated at the veneer outlet, controlled by the PLC to automatically cut the veneer once it reaches the preset length.

Veneer Conveying & Winding Mechanism: Gently transports and flattens the continuous peeled veneer, winding or stacking it as required.

Hydraulic/Pneumatic System: Provides power for auxiliary actions such as tailstock clamping and core ejection.

Lubrication & Cooling System: Ensures the precision and longevity of moving parts like guide rails and lead screws during prolonged operation.

Summary of Core Design Features

Integrated Process: Combines peeling, length measurement, and cutting into one automated, high-efficiency workflow.

Intelligent Control: Centered around the PLC and Servo System, ensuring thickness accuracy (±0.01mm) and process stability.

Specialized Structure: The spindleless design and heavy-duty bed provide a balance of multi-functionality and high rigidity.

|

Aoolications

Primarily used in plywood mills, wood-based panel plants, and furniture overlay factories for peeling production of various wood veneers.

|

Product Packaging

|

After-Sales Service & Support

Global Delivery: Export packaging (wooden case/steel frame) provided, supports CIF/FOB terms, assists with customs clearance documentation.

Installation & Commissioning: Dispatch experienced engineer teams to the customer's factory for installation guidance, equipment commissioning, and trial production.

Technical Training: Comprehensive theoretical and practical training for customer's operators, maintenance, and management staff until they can operate independently.

Warranty Commitment: 12-month warranty for the whole machine, lifelong technical consultation and paid spare parts supply.

Remote Support: 7x24 online technical consultation available, with remote diagnostics and troubleshooting via video call.

|

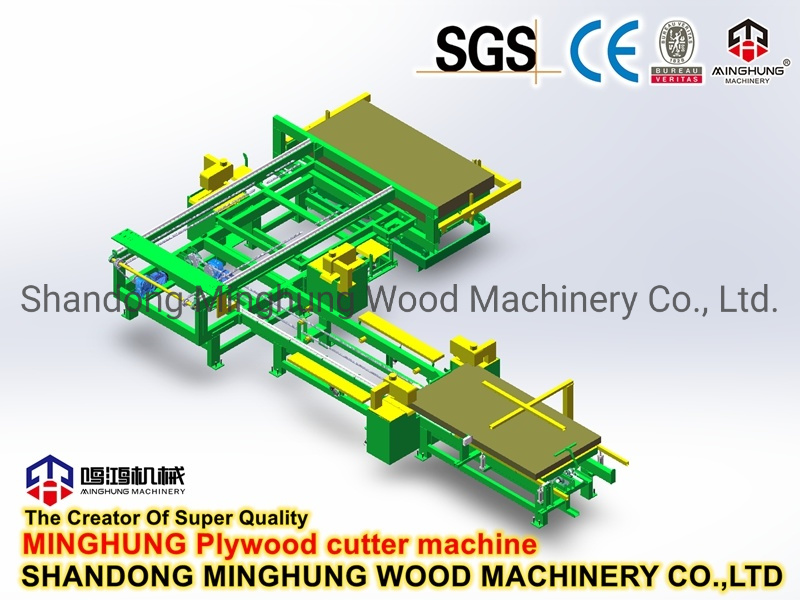

Company Profile

We are Shandong MINGHUNG Wood Based Panel Machinery Co.,Ltd China factory and manufacturer of full sets of Plywood machinery and Veneer machinery. With many years production experience, advanced production technology,experienced workers and professional engineers, we can offer you the suitable, good and strong machinery for you.

|

Certifications

Customize Your Plywood Solution Now! Plant layout design, on-site training & global logistics support – Build your competitive plywood brand today!

Whatsapp: +8618769900191 +8615589105786 +8618954906501

Email: osbmdfmachinery@gmail.com