|

Product Description

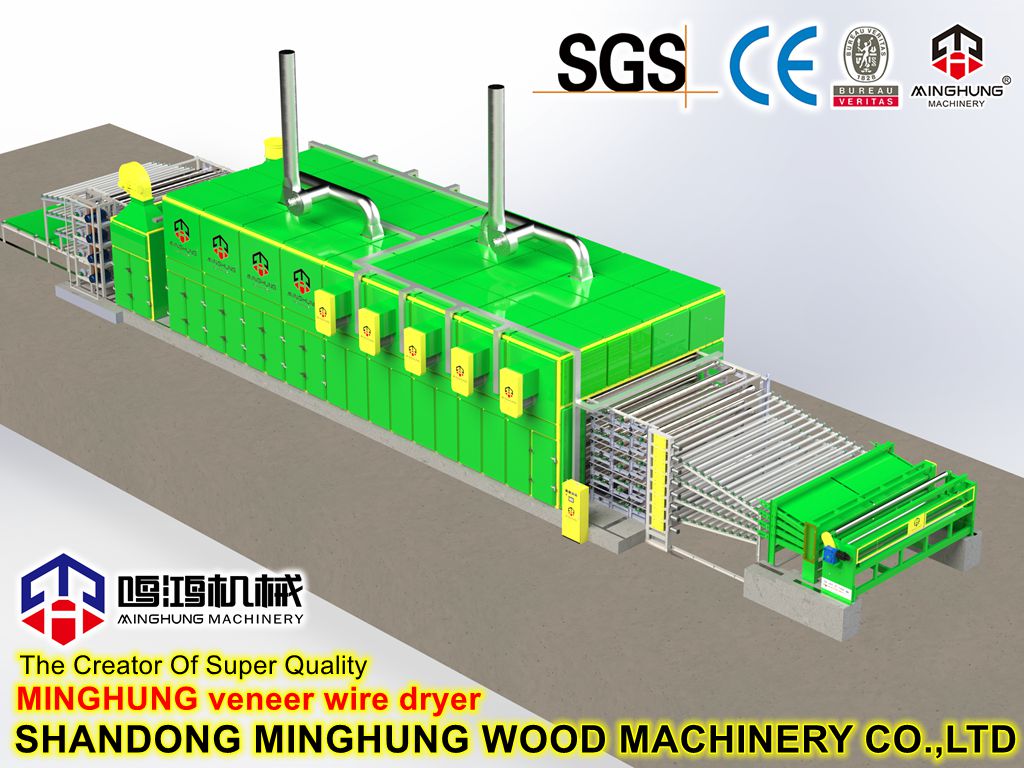

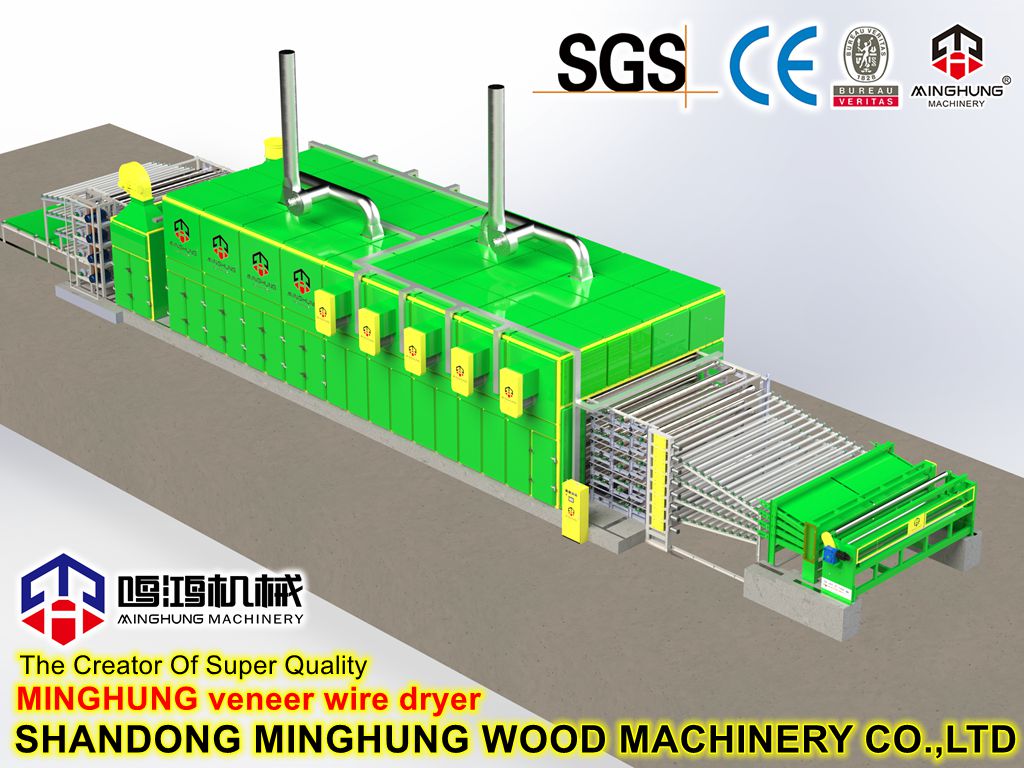

The Heat Recovery Veneer Drying Machine is a revolutionary high-efficiency veneer drying equipment in the modern wood processing industry. Designed to meet the demands of large-scale, continuous veneer production, it fundamentally addresses the drawbacks of high energy consumption and cost associated with traditional dryers by integrating advanced heat recovery technology.

|

Core Advantage

Exceptional Energy Savings and Efficient Drying

The core of this system lies in its innovative heat recovery system. In conventional drying processes, a large amount of exhaust gas carrying thermal energy and moisture is directly discharged, resulting in significant energy waste. Our Heat Recovery Veneer Dryer efficiently recovers the waste heat from this exhaust stream through a specially designed heat exchanger and uses the recovered energy to preheat the fresh air entering the dryer. This process dramatically reduces the additional energy required to heat fresh air, making it a veritable energy-saving wood dryer. Compared to standard equipment, it can save up to 30% in energy consumption, directly lowering operational costs for enterprises.

Intelligent Drying Process with Precise Control

To achieve optimal drying quality, the equipment is equipped with a sophisticated intelligent temperature and humidity control system. This system monitors and adjusts the temperature and airflow within the drying chamber in real-time, achieving precise veneer moisture control. This ensures the veneers are heated uniformly from the inside out, preventing both over-drying and under-drying, effectively reducing defects such as cracking and warping, and guaranteeing the final yield and quality of the veneer. This advanced veneer drying technology is fundamental for producing high-end plywood and quality furniture manufacturing.

Wide Application and Flexible Customization

As a high-performance industrial veneer dryer, it is widely used in various fields such as plywood, blockboard, furniture manufacturing, and flooring substrates. Understanding that different clients have varying production lines and raw materials, we offer customized veneer drying equipment services. Whether it's dealing with dimensions, initial moisture content, or specific capacity requirements, our engineering team can provide the best veneer drying solutions to ensure the equipment integrates perfectly into your production process.

Perfect Combination of Technology and Environmental Protection

The machine utilizes a hot air circulation design, which, combined with the heat recovery system, maximizes the utilization of every unit of thermal energy. This makes it not only economical but also a choice for an eco-friendly veneer drying system. It helps reduce greenhouse gas emissions and the consumption of fossil fuels, assisting enterprises in practicing green manufacturing.

|

Working Principle

The working principle of the Heat Recovery Veneer Drying Machine is based on hot air circulation and energy recovery technologies, forming a highly efficient and energy-saving closed-loop drying system.

1. Heating and Drying Phase: Clean hot air, generated by a burner (or steam heat exchanger), is forced by powerful circulation fans into the drying chamber. This hot air acts as the drying medium, penetrating through the stacked layers of wet veneers, absorbing and evaporating the moisture within.

2. Dehumidification and Heat Recovery Phase: The hot, moist air (exhaust) carrying absorbed moisture would normally waste significant energy if discharged directly. The core of this equipment is its heat recovery system: before being exhausted, this high-temperature, high-humidity air passes through a specially designed air-to-air heat recuperator. Here, a non-contact, cross-flow/counter-flow heat exchange occurs between the exhaust and the fresh, cold intake air.

3. Energy Reuse Phase: The sensible heat (from temperature) and part of the latent heat (from steam) from the exhaust are transferred to the fresh intake air, pre-heating it before it enters the heater. This means the heater requires significantly less energy (e.g., gas or steam) to raise the pre-heated air to the target temperature, thereby significantly reducing energy consumption.

4. Intelligent Control Cycle: The temperature, humidity, and air speed throughout the process are precisely regulated by an intelligent temperature and humidity control system. Sensors monitor the chamber conditions in real-time, automatically adjusting heater power, dehumidification damper opening, and fan frequency to ensure the veneer dries according to the optimal process curve, achieving uniform and efficient veneer drying.

This heat recovery technology transforms the traditional "open-loop" energy-intensive process into a "semi-closed-loop" energy-saving one, representing the technical essence of this comprehensive veneer drying solution.

|

Main Components

A complete Heat Recovery Veneer Drying Machine typically consists of the following core components:

1. Drying Chamber: Constructed with high-quality insulated panels (e.g., polyurethane sandwich panels) to form a sealed drying space, effectively preventing heat loss.

2. Heating System:

Heat Source: Options include gas/oil burners, steam heat exchangers, or electric heaters, depending on client conditions.

Heating Unit: Efficiently transfers energy from the heat source to the circulating air.

3. Heat Recovery System: The core energy-saving component, often a plate-fin heat exchanger, made of anti-corrosion materials like aluminum alloy or stainless steel, responsible for energy exchange between exhaust and fresh air.

4. Circulation Fan System: Comprises high-temperature resistant, high-pressure centrifugal fans that drive the forced circulation of hot air within the chamber, ensuring airflow evenly penetrates the veneer stacks.

5. Dehumidification System: Includes exhaust fans and adjustable dampers, responsible for expelling the cooled, moisture-laden exhaust air (after heat recovery) and introducing fresh air.

6. Intelligent Control System:

PLC Controller: The system's brain.

Temperature & Humidity Sensors: Monitor the drying environment in real-time.

HMI Touch Screen: For setting and displaying veneer drying technology parameters (e.g., drying curves).

Actuators: Control the actions of heating, dehumidification, dampers, etc., achieving precise moisture control and automated operation.

7. Veneer Loading Carts and Tracks: Facilitate easy loading/unloading and stacking of veneers, improving handling efficiency.

|

Main Technical Parameters

The following are typical technical parameter ranges for an industrial veneer dryer. Specific parameters support customized veneer drying equipment.

Parameter Category | Parameter Item | Typical Range / Description |

Drying Capacity | Single Load Capacity (Oven-dry wood) | 5-30 m³ (Larger capacity customizable) |

| Suitable Veneer Thickness | 0.5-4.0 mm |

Heat Source Option | Type | Natural Gas, Diesel, Steam, Electricity |

Temperature Range | Drying Temperature | 40-150 °C (Adjustable) |

Energy Consumption | Energy-Saving Effect | 25%-35% savings compared to conventional dryers |

Technical Specs | Hot Air Circulation Mode | Forced Horizontal or Vertical Circulation |

| Average Water Removal Efficiency | 1.5-3.0 kg water / kWh energy (Varies by equipment) |

Overall Dimensions | Equipment Size (L×W×H) | Customized based on capacity, e.g., 20m × 5m × 4m |

Control Precision | Temperature Control Precision | ±1.5 °C |

| Humidity Control Precision | ±3% RH |

In summary, this Heat Recovery Veneer Drying Machine is more than just a drying apparatus; it is a comprehensive veneer drying solution that integrates high-efficiency veneer drying, significant energy savings, intelligent control, and environmental philosophy. It represents the forefront of current veneer drying technology and is the ideal choice for modern enterprises striving to enhance production efficiency, reduce operating costs, and commit to sustainable development.

Our contacts:

Whatsapp: +8618769900191 +8615589105786 +8618954906501

Email: osbmdfmachinery@gmail.com