Roller Dryer for Drying Wood Veneer

Veneer drying

Veneer drying is very important for the production of plywood. After wood is produced into veneer through veneer lathe, the moisture content is 50-70%. Plywood production requires veneer moisture content of 8-%14. The moisture content of veneer is greater than %14, which brings negative The influences are: 1. It will increase the hot pressing time of the plywood blank in the hot press. The heating of the hot press is heated by a steam boiler or a heat transfer oil boiler. If the hot pressing time is increased, it is equivalent to an increase in heat loss. 2. If the moisture content is higher than %14, the veneer after glue spreading will seep out of glue during the hot pressing process, causing the plywood to crack. 3. If the moisture content of the veneer is 14%, the plywood blank needs to be dehumidified several times during the hot pressing process to remove the moisture inside the plywood blank. If the temperature is not properly controlled, there will be air bubbles in the semi-finished plywood, which will crack and cause the plywood to be scrapped.

MINGHUNG veneer drying effectively solves the problem of veneer drying, veneer drying, according to the density of different veneers, the customer's different veneer output, the factors of purchasing cost, MINGHUNG has developed a variety of veneer drying types MH-RD40L,MH-RD304HL / MH-2830L / MH-MD3618 : roller veneer drying, wire veneer drying, mesh veneer drying, press drying, square tube veneer drying, Hollow veneer drying, ect specialized in research on saving energy, energy consumption and improving production efficiency of veneer drying.

hello friends, we are SHANDONG MINGHUNG WOOD MACHINERY CO.,LTD, produce plywood machine and veneer machine with many years experience and advanced technology.

machine include the full line of plywood machine, like the log peeling machine, veneer dryer machine, glue machine, cold press machine, hot press machine, plywood saw machine, sanding machine.

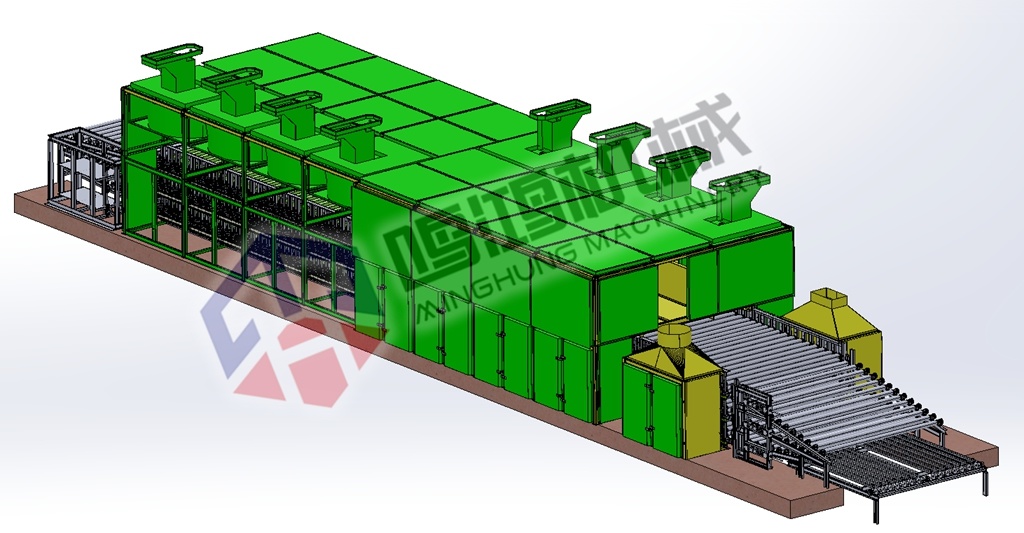

i am gonna introduce the veneer roller dryer machine for you. as we know, the roller dryer machine's function is drying original wood veneer after peeling it by the log peeling machine. and as its name, the inside transport by the material roll.

roller dryer are very popular in many countries. usually if clients require high drying capacity, roller dryer are very suitable, because this type veneer roll dryer can be different length and width and floors. usually the three floors and four floors are popular, and one section is two meter, so some clients will buy ten sections or fifteen sections according to their own conditions.

for the drying machine, the working quality should be very nice, thus the drying machine can work well, and at the same time, it can use long time, save your maintain time.

for the drying machine, the working quality should be very nice, thus the drying machine can work well, and at the same time, it can use long time, save your maintain time.

we can say that all main materials and parts of our roller dryer are the nice, thick and strong one. because we know clearly that only make sure our machine good and strong quality, that we can satisfied our customers requirements, and at the same time, help ourselves develop longer.

our company culture is: Be an excellent company, make staff happy, customers satisfied, and gains social recognition.

and we are improving our machine character and parts continuously. in every period, our machine will be inproved. we are really seriously do our business.

until now, we have exported many plywood machines to different countries, and get good feedback, many old clients buy from us again and agaiin, and glad introduce other people to us.

if you wants to start produce plywood or wood veneer, or any one of plywood machine you need, welcome contact us, we have the confidence and sincerity offer you good and strong machine.