|

Techical Overview

Designed Annual Capacity: 10,000 - 12,000 tons (based on specific thickness)

Applicable Material: Rotary-cut veneer of Poplar, Eucalyptus, Pine, Mixed Hardwood, etc.

Input Moisture Content: 40% - 60% (wet basis)

Output Moisture Content: 8% - 12% (±2%) (Adjustable)

Heat Source Options: Biomass, Natural Gas, Steam, Thermal Oil

Control Method: Fully automatic PLC + Touch Screen control, supports remote diagnostics

Installation: Modular on-site assembly

|

Working Principle

The core working principle of this system is "continuous, zone-controlled convective hot air drying."

Wet veneer sheets are evenly laid onto a conveyor mesh belt at the feeding end. The belt then carries the veneer continuously at a constant speed through an elongated drying tunnel divided into multiple stages.

Throughout this journey, the veneer sequentially passes through three main phases:

1. Preheating Zone: In this initial stage, the system creates a low-temperature and high-humidity environment. The objective is to heat the veneer gently and uniformly, preventing the surface cell walls from cracking due to sudden exposure to high heat.

2. Constant Rate Drying Zone: This is the stage of most intense moisture evaporation. The system applies the highest temperature and air velocity here. Powerful hot air is forced through the veneer layers, rapidly carrying away the free water within. The system precisely controls the exhaust volume to maintain appropriate humidity, preventing the veneer surface from hardening too quickly (case-hardening) and ensuring internal moisture continues to migrate outward.

3. Falling Rate Drying Zone: Once the veneer's moisture content falls below the fiber saturation point, evaporation shifts from the surface to the release of water from within the cell walls, and the rate slows. This phase requires gentler drying conditions. The system lowers the temperature and increases humidity (by reducing exhaust) to prevent excessive stress that could cause warping or cracking, thereby safely removing the bound water within the cell walls.

Throughout the entire process, the Intelligent Central Control System, via a network of temperature and humidity sensors distributed across all drying zones, continuously monitors the environmental conditions. It dynamically adjusts the heat output of the air heaters, the speed of the circulation fans, the opening of the exhaust dampers, and the speed of the mesh belt. This ensures the veneer strictly adheres to the pre-set optimal drying curve from start to finish. This real-time data-based closed-loop control is the key to achieving high annual output, superior quality, and low energy consumption.

|

Core Components and Their Functions

1. Modular Drying Chamber

An extremely elongated, insulated box-type tunnel divided into multiple drying stages. It employs a modular design for on-site assembly and is filled with high-quality thermal insulation material. Its function is to form a continuous, well-insulated drying space, providing a stable environment for the veneer to complete the entire drying journey while minimizing heat loss.

2. High-Efficiency Air Heater Cluster

To meet the enormous thermal demand, multiple large-capacity, high-efficiency air heaters (e.g., biomass, gas-fired) typically work in parallel or series. Its function is to provide a stable, ample, and efficient heat source for the entire system, acting as the "heart" that ensures the driving force for drying.

3. Zoned Circulation Fan System

Multiple high-power, high-pressure centrifugal fans, each independently controlled by a Variable Frequency Drive (VFD), are installed at the top and bottom of each drying zone. Their function is to generate powerful, independently adjustable vertical penetrating airflow within their respective zones, ensuring hot air forcefully and evenly passes through the thick veneer layers. This system is the "powerhouse" for efficient heat and mass transfer.

4. Intelligent Moisture Exhaust System

Electrically actuated exhaust dampers are installed in each drying zone. Their function is to precisely control the degree of damper opening based on real-time humidity sensor data from that specific zone. It expels large amounts of moisture in high-temperature zones and reduces exhaust in humidity-maintaining zones, thereby meticulously managing the humidity environment at each stage of the drying chamber. This is key to guaranteeing drying quality.

5. Heat Recovery System

A large air-to-air heat exchanger (e.g., heat pipe or plate type). Its function is to facilitate heat exchange between the outgoing high-temperature, high-humidity exhaust air and the incoming fresh cold air, recovering over 60% of the heat energy from the exhaust to preheat the fresh air. This is crucial for a 10,000-ton capacity system, as it directly and significantly reduces the load on the main heating system, resulting in substantial energy cost savings.

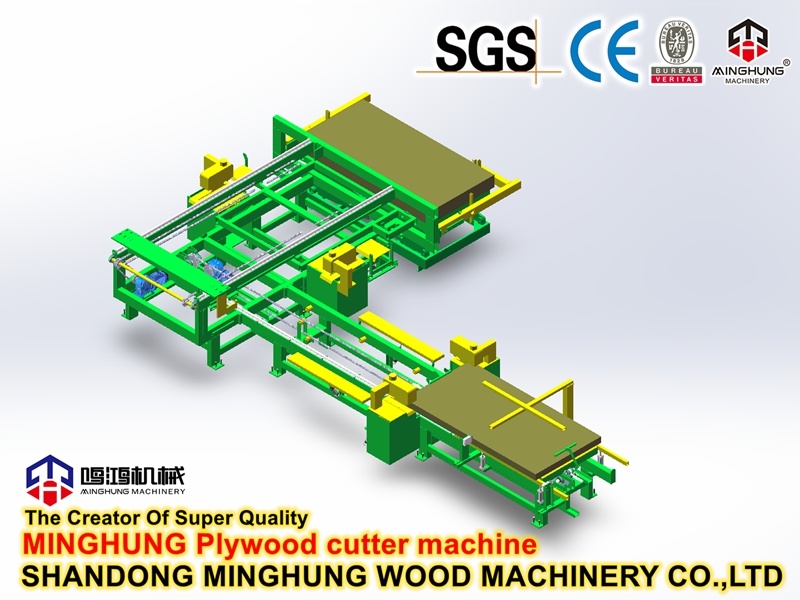

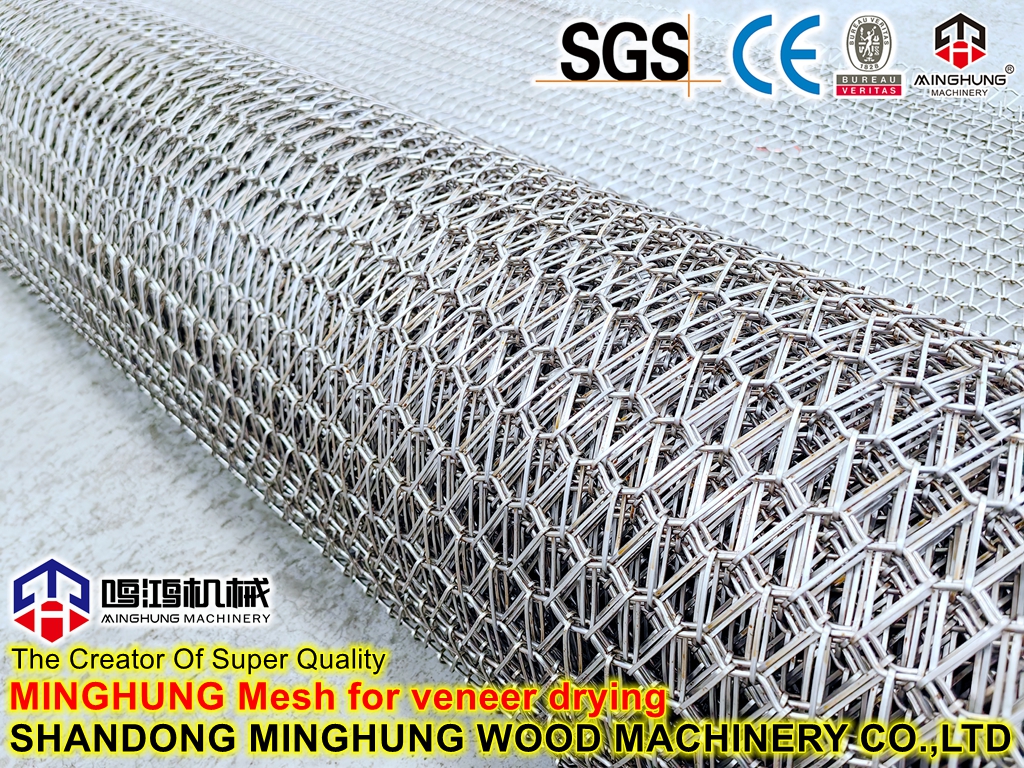

6. Continuous Conveying System

Comprises a heavy-duty metal mesh belt, drive sprockets, tensioning devices, and a multi-motor drive system. Its function is to carry the veneer smoothly and continuously at a constant, adjustable speed through the entire drying tunnel. The stability and speed of its operation directly determine the system's output and drying time.

7. Central Intelligent Control System

The "nerve center" of the system. It includes an Industrial PC (IPC) or large PLC, a touchscreen HMI, and a network of temperature and humidity sensors and online moisture detectors throughout all zones. Its functions include cluster control (coordinating multiple heaters, fans, and dampers), storing and executing hundreds of drying recipes, 24/7 real-time monitoring and optimization of all operating parameters, generating production reports, and enabling data management and remote diagnostics to ensure consistent quality and efficient production.

8. Automated Material Handling System

Includes an automatic spreader (infeed) and an automatic stacker (outfeed). Its function is to automate the even laying of wet veneer and the stacking and collection of dried veneer. For a 10,000-ton system, this is a key component for achieving full-line automation, significantly saving labor, and ensuring a smooth workflow.

|

Certifications

|

Exhibition

|

Package and Transport

We provide comprehensive turnkey project services, from site survey, solution design, equipment manufacturing, installation & commissioning, personnel training, to after-sales support, ensuring smooth project launch and the achievement of expected goals.