Product Positioning and Design Philosophy

Positioning:

The Economic OSB Starter Production Line is a cost-effective solution targeting small and medium investors, start-ups, and specific regional markets. It is not a top-tier "flagship" product but a practical setup designed to help clients quickly establish production capacity and capture local or niche markets with the lowest possible initial investment barrier.

Design Philosophy:

Its core philosophy is "Focus on the Core, Simplify the Periphery." This means guaranteeing the most fundamental aspects of OSB—the oriented structure and basic mechanical properties—while significantly reducing complexity and overall cost by optimizing configuration, selecting cost-effective components, and streamlining non-essential processes.

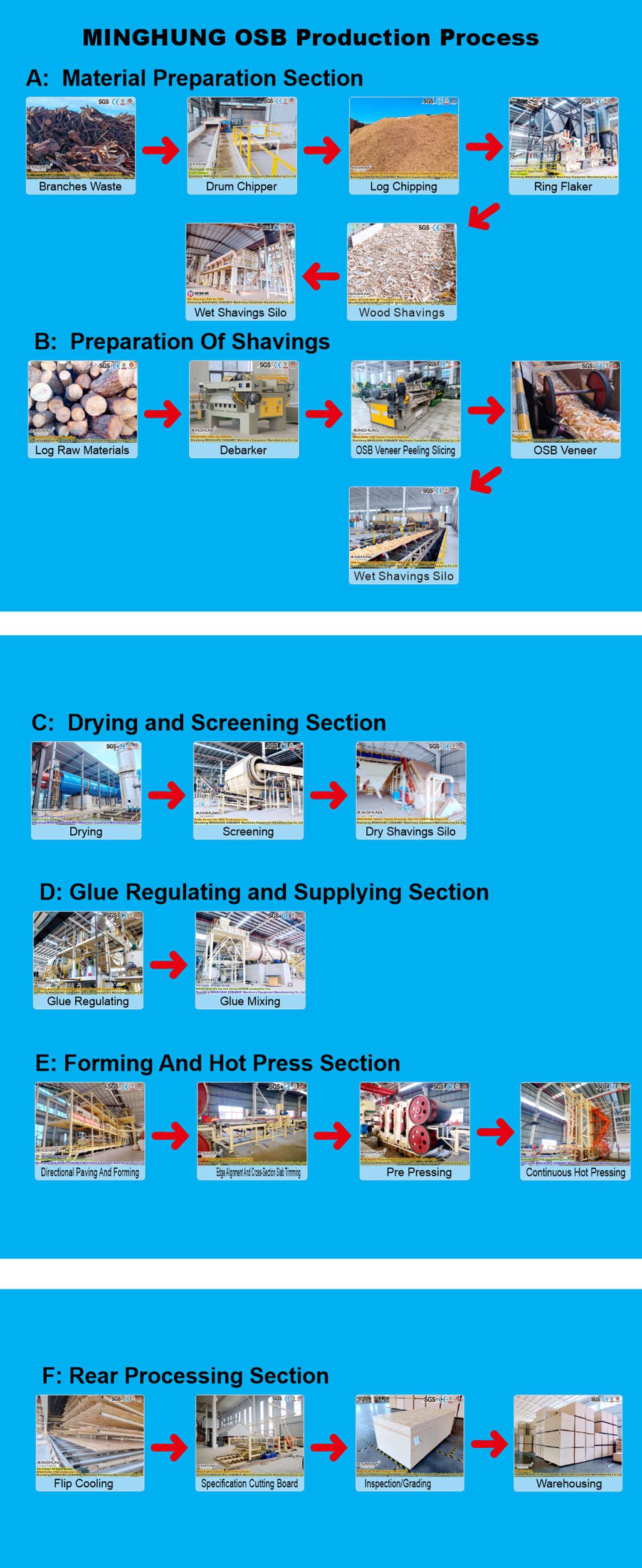

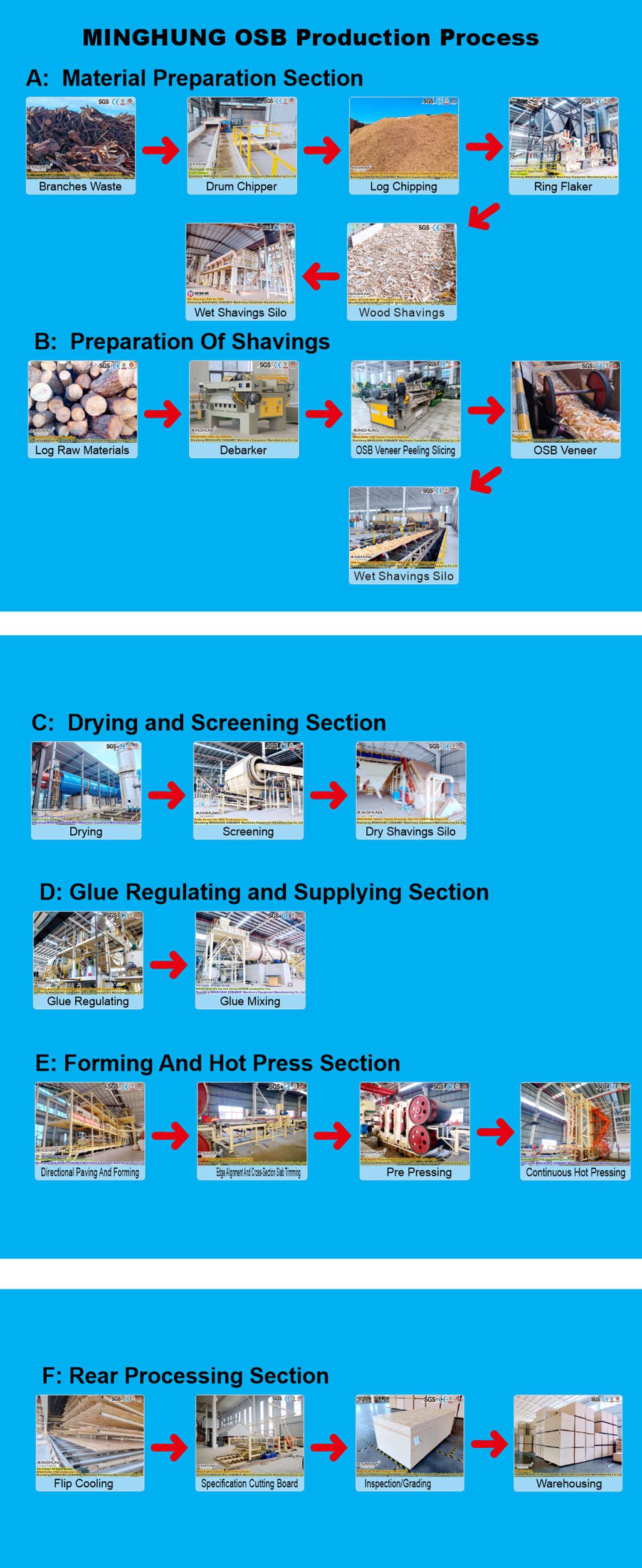

What is the Production Process of an Economic OSB Starter Line?

Step 1: Raw Material Preparation - Simplified Handling

Standard Full-Line Practice: Incoming logs → Debarking → Chipping → Washing & Screening.

Economic Line Practice:

Preferred Solution: Directly purchase commercial wood chips. This eliminates the need for large initial equipment like debarkers and chippers, representing the most effective way to reduce investment costs.

Alternative Solution: Use low-cost raw materials like small-diameter logs, branches, etc. These may only undergo simple crushing or chipping, omitting the washing step, resulting in a more lenient requirement for raw material cleanliness.

Step 2: Strand Preparation - Guaranteeing the Core

This is a core section that cannot be overly simplified, as strand quality directly determines board strength.

1. Stranding: Wood chips are fed into a Strander and sliced into thin, flat strands of the designed specification. Qualified strand morphology is equally crucial for an economic line.

2. Drying: Wet strands are passed through a Dryer (which might be a slightly less efficient but more cost-effective model) to reduce moisture content from 30%-50%+ down to 2%-4%. This is a prerequisite for hot pressing.

3. Screening: Dried strands are classified via a Vibrating Screen. The screening efficiency and precision in an economic setup might be slightly lower, generating more fines and overs, but it must separate qualified core and face layer strands.

Step 3: Blending & Forming - The Soul of OSB

This is the "soul" of OSB production and remains core even in an economic line.

1. Blending: Screened strands are uniformly mixed with adhesive (typically MDI resin for its superior waterproofing and fast curing) and wax in a High-Speed Blender. The economic line might use a blending system with sufficient metering accuracy but lower cost.

2. Oriented Forming:

Method: Employs a Purely Mechanical Strand Orienting Former (instead of an expensive airflow-assisted type). Resinated strands fall onto high-speed rotating Orienting Rolls with special grooves and are aligned by friction.

Structure: Typically a three-layer structure: The top and bottom surface layers use finer, longer strands oriented along the panel's length direction; the middle core layer uses coarser, shorter strands oriented along the width direction or randomly. This structure ensures longitudinal strength while balancing transverse strength and controlling cost.

Step 4: Hot Pressing - Core Consolidation

This is one of the most distinct differences compared to high-end production lines.

1. Pre-pressing: The loose, oriented mat is first passed through a Pre-press for initial compaction and shaping, forming a stable "mat blanket" for transport and loading into the hot press.

2. Hot Pressing:

Equipment: Uses a Multi-Opening Hot Press, not a continuous press.

Process: This is batch production. The pre-pressed mat is cut to length and loaded sheet by sheet into the layers of the multi-opening press. The press then closes, applying high temperature and pressure to rapidly cure the MDI resin within tens of seconds to a few minutes.

Comparison: A continuous press allows the mat to pass through uninterrupted. The multi-opening press has a lower investment cost but limits production capacity and panel size flexibility.

Step 5: Finishing - Simplified Handling

1. Cooling & Trimming: The hot pressed panels are discharged from the press and enter a Cooling and Turnover Device for cooling and setting. They are then cut to standard sizes by Cross-Cut and Rip Saws.

2. Stacking & Packaging: The cut panels are stacked by a Semi-or Fully-Automatic Stacker and finally packaged manually or semi-automatically.

Simplification Point: Economic lines often omit the online sanding process. The thickness tolerance and surface smoothness of the panels might be slightly inferior, or sanding is conducted as a separate offline process.

Summary of Key Characteristics of the Economic Process

1. Intermittent Production: Due to the use of a multi-opening press, production occurs "sheet by sheet," rather than continuously.

2. Moderately Higher Labor Dependency: More manual involvement might be needed in areas like raw material feeding, mat handling, and packaging.

3. High Flexibility: Easy to change product thickness, suitable for small-batch, multi-specification orders.

4."Fit-for-Purpose" Quality Standard: The OSB panels produced fully meet the basic requirements for structural materials, possessing good strength and moisture resistance. However, they might differ from top-tier products in "refined" indicators like appearance and thickness uniformity.

In conclusion, the economic OSB production process is a practical line that captures the core technologies of "oriented forming" and "hot press curing," while achieving excellent cost control through the use of multi-opening presses and simplified upstream/downstream processes. It serves as an ideal stepping stone for entering the OSB manufacturing industry.

An economic OSB starter line is designed to meet core production needs while significantly reducing investment costs. Its equipment configuration follows the principle of "Focus on the Core, Simplify the Periphery."

1. Raw Material Handling Section

Chipper: For cutting logs or branches into wood chips, if raw wood is used.

Simple Vibrating Screen: For screening chips to separate out oversized and undersized fragments.

Common Simplifications / Options:

Large Debarkers and Chip Washers are typically omitted. Purchasing commercial wood chips is recommended to eliminate the need for this entire pre-treatment stage and save space.

2. Strand Preparation Section

Strander: Key equipment for slicing wood chips into standard OSB strands. An economic line is typically configured with a disc or drum strander of sufficient capacity.

Dryer: A rotary drum dryer used to reduce strand moisture to the required low level. May use coal or biomass fuels to lower operating costs.

Dry Strand Screen: Usually a multi-deck vibrating screen for classifying dried strands into face-layer, core-layer, and waste material.

Common Simplifications / Options:

Screening efficiency and precision might be slightly lower than in high-end lines, resulting in a slightly lower strand yield.

3. Blending and Forming Section (Core Section)

Strand Bins: For storing dried face and core strands separately.

Metering Devices: Belt scales or volumetric metering hoppers to control the ratio of strands to resin.

High-Speed Blender: Core equipment for uniformly mixing strands with MDI resin and wax.

Mechanical Strand Orienting Former: The soul of the production line. Uses grooved orienting rolls to align the strands on a moving conveyor mat, creating the oriented structure. Possesses the basic capability to form a three-layer mat (face-core-face).

4. Pressing and Curing Section

Mat Pre-press: Initially compacts the fluffy formed mat to increase density for easier handling and loading into the hot press.

Mat Cross-Cut Saw: Cuts the continuous mat into lengths matching the hot press dimensions.

Loading/Unloading System: Can be mechanized or semi-automated, used to feed the mats into the multi-opening hot press and remove the hot panels.

Multi-Opening Hot Press: The hallmark equipment of an economic line, replacing the expensive continuous press. It operates on a batch production principle, pressing multiple mats simultaneously between multiple heated platens.

Heating System: Typically a thermal oil heater, providing the heat source for the hot press.

5. Finishing Section

Cooling and Turnover Device: Cools the hot panels from the press and allows them to set uniformly.

Panel Sizing Saws (Cross-Cut & Rip Saws): Cuts the cooled large panels into market-required final dimensions.

Stacker: Automatically or semi-automatically stacks the finished panels neatly.

Common Simplifications / Options:

An Online Sander is typically not included. Surface finishing may be done via offline sanding, or the panels are sold as unsanded.

6. Control System

PLC (Programmable Logic Controller) Control System: Provides automated control and interlocking for the line's core equipment (e.g., forming, pressing, drying), ensuring safe and continuous operation.

Common Simplifications / Options:

The system is less sophisticated, likely lacking plant-wide centralized control or advanced data analysis functions, but is fully capable of ensuring stable production.

Key Features and Advantages

1. Very Low Investment Threshold: This is its core advantage. The total investment can be as low as 1/5 to 1/3 of a fully automated continuous press line, significantly lowering the financial barrier to entry.

2. Rapid Production & ROI: The relatively simple equipment structure shortens installation and commissioning, allowing clients to produce sellable products and generate ROI faster.

3. Core Technology Retained: Despite being economic, the crucial processes of oriented forming and hot pressing are strictly retained, ensuring the output is genuine Oriented Strand Board with its core structural strength advantages, not just ordinary particleboard.

4. Low Operating Costs:

Energy Consumption: Multi-opening presses consume less energy compared to massive continuous presses.

Maintenance: Simple structure allows for easier maintenance with lower technical skill requirements.

Labor: While not fully automated, reasonable crew design can still effectively control labor costs.

5. High Flexibility:

Raw Material Flexibility: More tolerant of various raw materials, easily utilizing small-diameter wood, branches, and even some recycled wood.

Product Flexibility: Easier to changeover for producing panels of different thicknesses, suitable for small-batch, multi-specification orders.

6. Small Footprint: The compact design requires less factory space, further reducing initial civil construction costs.

Target Markets and Applications

Start-up Wood Processing Companies: Investors looking to enter the OSB sector with a limited budget.

SME Panel Plant Upgrades: Existing particleboard or MDF plants seeking a low-cost upgrade to add an OSB product line.

Regional/Specific Markets:

Developing Markets: Meeting the huge demand for low-cost structural panels in basic construction.

Niche Application Markets: Such as focusing on OSB for packaging pallets or simple construction, where ultimate surface quality is less critical than cost and strength.

Resource Recycling Enterprises: Adding value by utilizing locally abundant, low-cost fast-growing timber or wood processing residues.

We provide comprehensive services from equipment supply and installation/commissioning to operational training, acting as your reliable partner in starting your OSB manufacturing business.

Contact us for a free quote today!

Our contacts:

Whatsapp: +8618769900191 +8615589105786 +8618954906501

Email: osbmdfmachinery@gmail.com