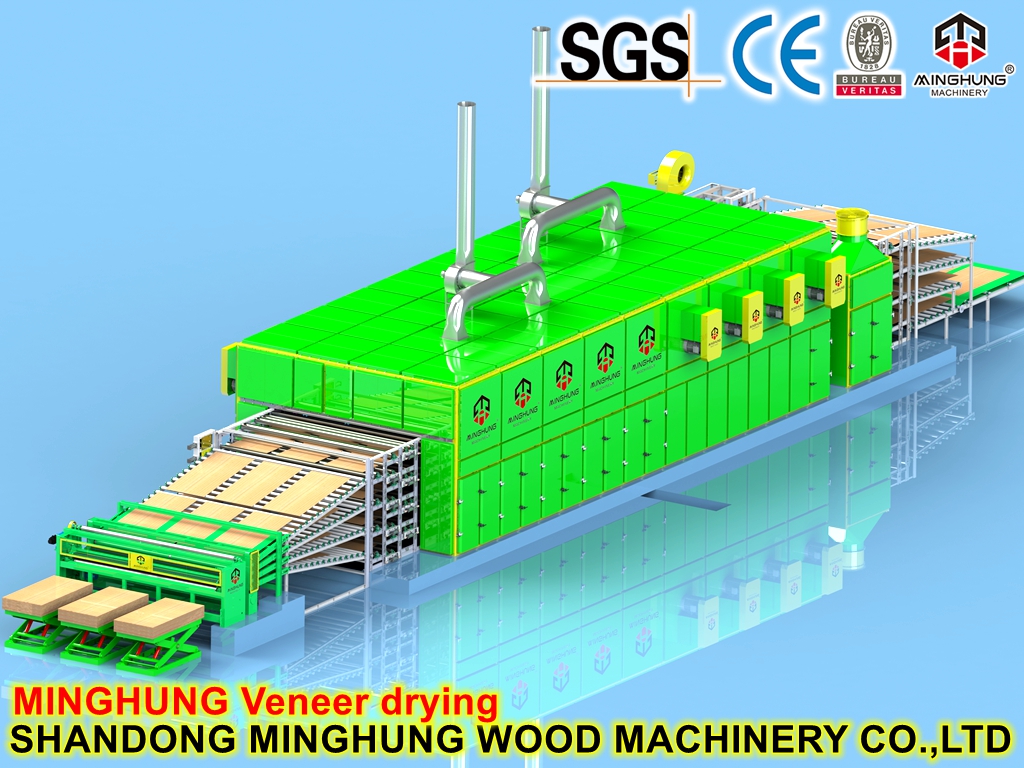

Plywood and Veneer Production Line

Dear friends, This article will tell you the steps for producing wood veneer, some also call it wood foil, and what kind of machines required for producing veneer, after read this, you will know clearly that before you start producing wood veneer, what things you need to do.

Veneer is a thin slice of wood made by rotary cutting or slicing or peeling of the log. The appearance of veneer varies and it depends on how the log is cut. Wood veneer is the material for making plywood, wooden furniture, so if wood veneer quality is very good, the end product like plywood, furniture will be good quality too, this will be very helpful for your business.

And how to produce good quality wood veneer? This is closely related with veneer machine, veneer peeling machine is the necessary machine for producing wood veneer, the principle of veneer peeling machine is: through rotate wood log under the driving of motor, processing wood log into pieces of wood veneer.

Now let’s start one by one :

First: Soften Log:

Before the peeling process, if your wood is very hard, it is better put log into water in order to cut it into smooth veneer of even thickness.

Second: Wood Debarker/log debarker:

wood log debarker’s function is processing wood for removing bark and make wood round. Wood debarker is easy to operate, and its structure not complex, through the forward and back of hydraulic cylinder, finish the debarking work.

Usually the standard size of log debarker is 4feet and 8feet. the max wood diameter of 4feet machine can be 600mm, the max log diameter of 8feet debarker can be 700mm. And if your log diameter is bigger more, like 1000mm, then should use spindle veneer machine.

Third: Veneer Peeling Machine/veneer lathe machine:

the spindleless veneer peeling machine, consist by machine frame, rollers, motors, electric box, cnc screen, through Setting up the veneer thickness and width through cnc screen, then put log and open starting button, veneer machine will start automatically working. As the peeler wood rotates against the knife, it is peeled into veneer.

Different veneer peeler, different configuration.

If the veneer machine for peeling softwood like poplar, then the machine configuration is common and need not require high, the power of veneer peeling machine also need not too much, because soft wood is more easier to processing.

But if your wood log is hardwood like beech, birch, acacia wood, then it requires the veneer peeler is strong enough, more powerful and heavy duty to keep the wood veneer thickness accurate and balance.

And the speed, thickness range, structure, and others of veneer peeling machine will be different.

The standard size of veneer peeling machine has 4feet(max log length 1300mm) and 8feet(max log length 2600mm), also can be customized according to your conditions.

| Length: 2700mm

Max diameter: 600mm

Thickness: 0.5-4.0mm

Total power: 60.5kw

Weight: 13t

Size: 5200*2300*1500mm |

| Length: 2700mm

Max diameter: 600mm

Thickness: 0.5-4.0mm

Total power: 46.9kw

Weight: 11t

Size: 5200*2300*1500mm |

| Length: 2700mm

Max diameter: 600mm

Thickness: 0.3-3.0mm

Total power: 53.6kw

Weight: 10t

Size: 5200*2300*1500mm |

The Purpose Buying Veneer Peeling Machine:

produce good quality wood veneer, accurate and balance thickness, surface smooth. be helpful for your business, whatever you use by yourself for making plywood or wooden furniture, or you sell to your clients.

This is what our factory focus on, make sure offer the good and suitable veneer peeling machine for you.

In general, veneer peeling machine has 4feet/5feet and 8feet/9feet, their configuration will be very different according to different requires. One type is not suitable for all people, so we always produce machinie according to our clients own conditions, make sure offer the most suitable machine to them.

Parts of Veneer Peeling Machine:

Wood Veneer Test:

If veneer peeling machine can not produce good quality wood veneer, then that is not a good machine.

When finish production of veneer machine, our engineer will test many times of different thickness, to test and check machine quality, ensure veneer thickness accurate and balance.

Many our clients came to visit our factory and measure thickness, then they usually will give a thumps-up geature.

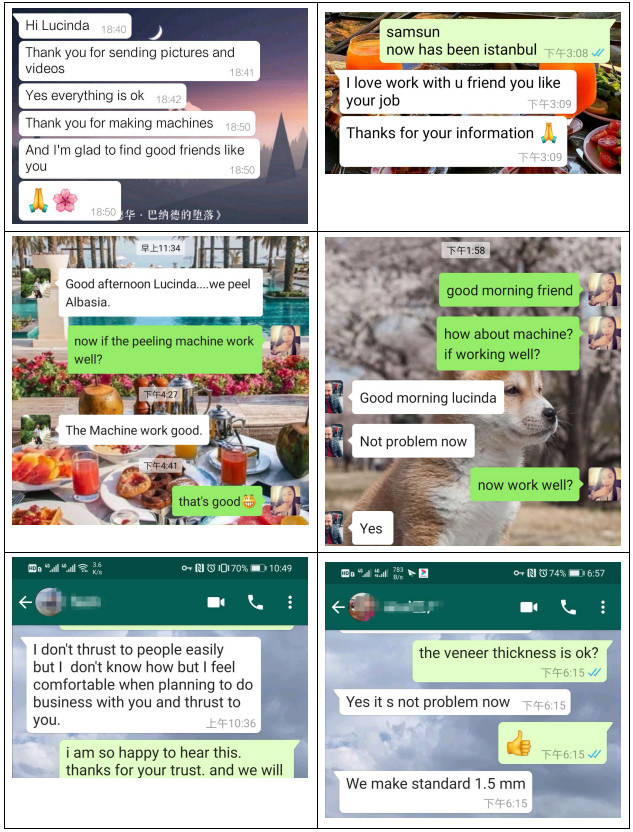

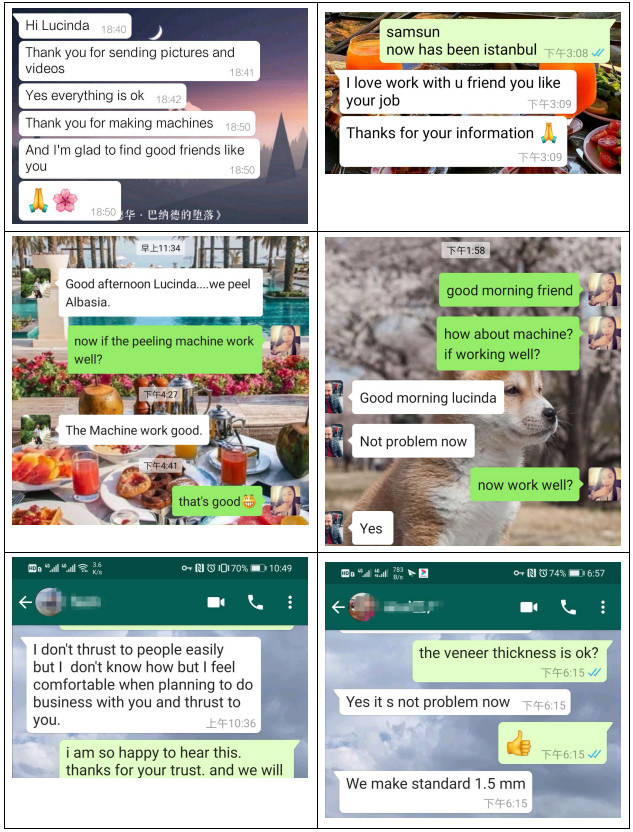

Clients:

With our clients, we not just partners, we are friends.

With our clients, we not just partners, we are friends.

Treate our friends, what we want to do and we are doing is: try help their business going better and better!!!

Help them design plant layout, offer them good and suitable plywood machine, machine drawings, technical support, reply at the first time.

Build a good and long relationship with you.

Clients Comment:

Delivery:

Related Machine:

Contact:

Whatsapp: +8618769900191 +8615589105786 +8615805493072

Website: www.plywoodmachineline.com

Email: minghungmachinery@gmail.com