8feet Veneer Peeling Machine for Birch Beech Eucalyptus Hardwood

Dear Friends,

The world is so big, suppliers so many, if we meet, that's our destiny.

Such special chance, we cherish, so we must will offer you good and suitable machine, be your good partner and friend in China.

For save your precious time, please do not be hesitate send message to me, i will offer you information according to your needs.

Length: 2700mm

Max diameter: 600mm

Thickness: 0.5-4.0mm

Total power: 60.5kw

Weight: 13t

Size: 5200*2300*1500mm |

Length: 2700mm

Max diameter: 600mm

Thickness: 0.5-4.0mm

Total power: 46.9kw

Weight: 11t

Size: 5200*2300*1500mm |

Length: 2700mm

Max diameter: 600mm

Thickness: 0.3-3.0mm

Total power: 53.6kw

Weight: 10t

Size: 5200*2300*1500mm |

The Purpose Buying Veneer Peeling Machine:

produce good quality wood veneer, accurate and balance thickness, surface smooth. be helpful for your business, whatever you use by yourself for making plywood or wooden furniture, or you sell to your clients.

This is what our factory focus on, make sure offer the good and suitable veneer peeling machine for you.

In general, veneer peeling machine has 4feet/5feet and 8feet/9feet, their configuration will be very different according to different requires. One type is not suitable for all people, so we always produce machinie according to our clients own conditions, make sure offer the most suitable machine to them.

Parts of Veneer Peeling Machine:

Wood Veneer Test:

If veneer peeling machine can not produce good quality wood veneer, then that is not a good machine.

When finish production of veneer machine, our engineer will test many times of different thickness, to test and check machine quality, ensure veneer thickness accurate and balance.

Many our clients came to visit our factory and measure thickness, then they usually will give a thumps-up geature.

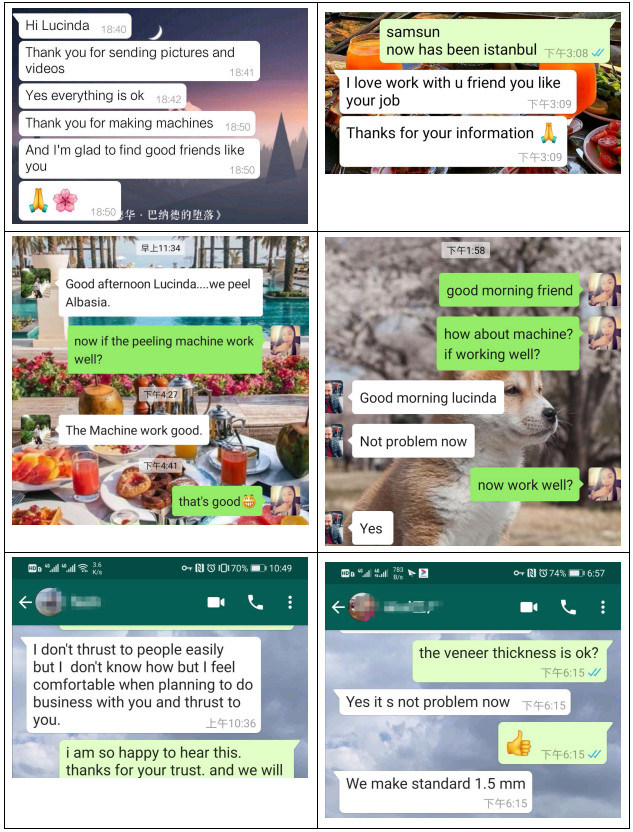

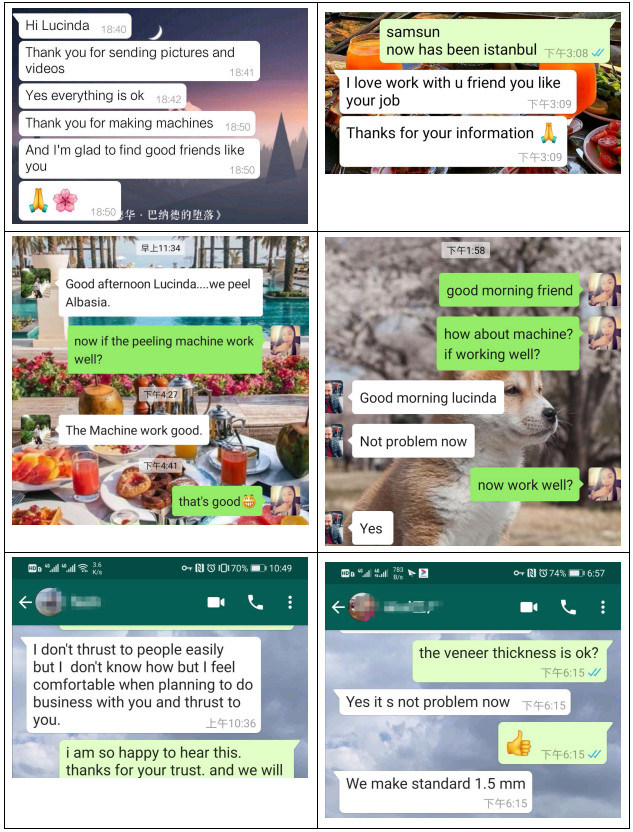

Clients:

With our clients, we not just partners, we are friends.

Treate our friends, what we want to do and we are doing is: try help their business going better and better!!!

Help them design plant layout, offer them good and suitable plywood machine, machine drawings, technical support, reply at the first time.

Build a good and long relationship with you.

Clients Comment:

Delivery:

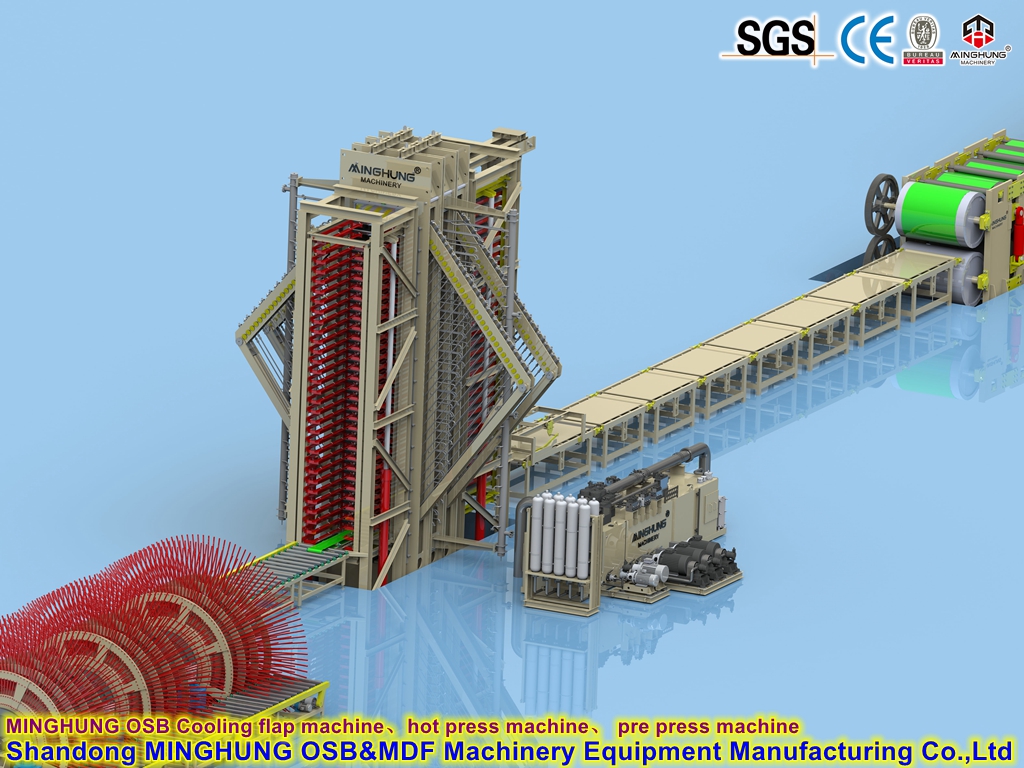

Related Machine:

Contact:

Whatsapp: +8618769900191 +8615589105786 +8615805493072

Website: www.plywoodmachineline.com

Email: minghungmachinery@gmail.com