Double Sides Two Pair of Sanding Heads Belt Frame Plywood Sander Machine

High Efficiency Single Side Wide Belt Sanding Machine for Wood Producing Line

There are also one or more sanding heads. These can be configured in different ways depending on the desired sanding effect. For example, there may be a combination of coarse sanding heads to remove rough surfaces and fine sanding heads to achieve a smooth finish.

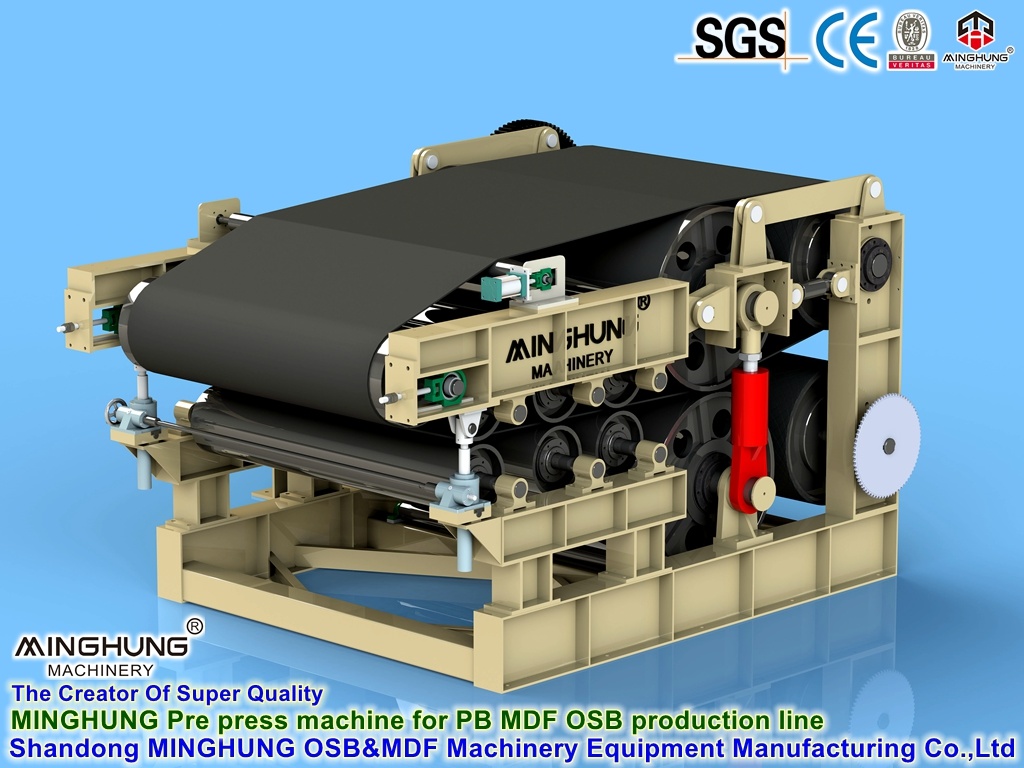

**Sanding Mechanism**

The sanding heads contain abrasive materials, usually in the form of sanding belts or sanding discs. The sanding belts or discs rotate at high speeds to remove the top layer of the plywood, smoothing out any imperfections. The machine may have the ability to adjust the pressure applied by the sanding heads, allowing for different levels of sanding intensity.

**Control System**

It is equipped with a control panel that allows operators to adjust various parameters such as the conveyor speed, the rotation speed of the sanding heads, and the sanding depth. This enables precise control over the sanding process to meet different quality requirements.

**Applications**

Plywood sanding machines are used in the plywood manufacturing industry to improve the surface quality of plywood before it is used in further processing or as a final product. They can also be used in woodworking shops that work with plywood for furniture making, construction, and other applications. The smooth surface achieved by the sanding machine is essential for painting, veneering, or simply providing a better aesthetic appearance.

In summary, the profile of a plywood sanding machine includes its structure, sanding mechanism, control system, and applications, all of which are designed to efficiently and accurately sand plywood to meet the quality standards required in the woodworking and related industries.

Whatsapp: +8618769900191 +8615805493072 +8615589105786