High Quality L Type Veneer Teech Joint Composing Machine for Wood Based Panel Plywood Production

| Introduction of L type core composer with Tooth joint |

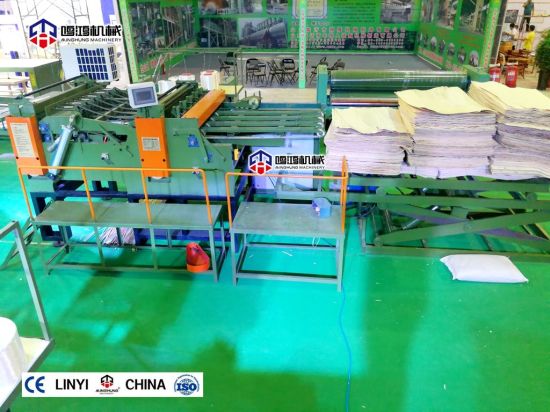

This is L type teeth veneer composing machine with teeth joint, its function mainly for joint veneers for making plywood board.

This core composer mainly for producing plywood board, it will automatic cut veneer edge, and joint veneers together and be the required plywood size.

Because it is tooth shape joint, so the veneer become more stronger, and the surface more balance, it will big improve your plywood quality.

It is not the necessary machine for making plywood, but if you want produce high quality plywood, the veneer composer must will be helpful.

Except the standard 4*8feet plywood, we also can customize the composing machine as your size and requires.

L type veneer core composer with Tooth joint

Teech veneer composing machine

| Advantages of Our veneer composing machine |

Teeth cutting

This composing machine with Teech cutting and connecting. Therefore the jointed shape is as teeth. The advantage of this teech shape joint is: The jointed veneer will become more stronger, and the

Auto stacker of core composer

After joint veneers, machine will automatic stack the jointed plywood, no need workers, save your labor cost and improve work efficiency.

Glue thread

Glue thread and glue particle are required for veneer composing machine. Machine includes max 7pcs glue thread, according to your veneer size, you can choose use all of them or 6pcs or 5pcs

Glue particle

Core composing machine inside has glue particle, for glue on the connect gap, make the joint more stronger.

Also we designed the veneer composing machine with the input entrance for easy put glue and keep worker safety

Teeth jointed veneer

Jointed veneer with teech connection

As picture showed, its connect is teech shape. With this shape joint, the veneer will be more stronger, and more balance

| Specification of L shape Veneer core composer with Tooth joint |

| Name | Veneer core composer with Tooth joint |

| Plywood size | 4*8feet or as required |

| Working way | Semi automatic |

| Front conveyor power | 3kw |

| Front cutter power | 2.3kw |

| Joint conveyor | 3kw |

Rear cutter

| 2.3kw |

| Synchronization | 3kw |

| Tooth pre-loader | 1.5kw

|

| Tooth pressing device | 7.5kw |

| Middle conveyor | 3kw |

| Rear conveyor | 3kw |

| Read cutter | 3kw |

Lifting

| 3kw |

| Stacking | 1.5kw |

| Heating device | 13kw |

| Air-conditioner | 1.5P |

| Weight | 13000 kgs |

Please note: The specific veneer core composer can be customized as your requires

| Other type Core composer for plywood production |

This type is the standard core composer, without L shape, without tooth joint. It directly cut the edge of veneer, and joint them, and automatic stack them

| Who we are? |

Plywood making machine

MINGHUNG Plywood making machine

As China professional factory and supplier of Plywood making machinery and Veneer lathe, we have been in this industry many years and keep to continuous to improve our machines, and insist use good materials and spare parts, therefore, now for our woodworking machinery, we are confident to tell you that they are on the top in China, it can help you produce good quality plywood board, and works very well.

Machines mainly includes: Log debarker machine, Wood peeling machine, Veneer stacking machine, Veneer dryer machine includes roller dryer, msh dryer, and press dryer; Plywood assembly line, Veneer core composer, Glue mixer, Glue spreader machine, Cold press machine, Hot press machine, Film hot press, Melamine MDF press machine, Plywood cutting machine includes the automatic roller type plywood sizing machine, Sanding machine/calibrating machine /polishing machine, Plywood overturn machine, Lift table and so on

As your own conditions and requires, we can design and offer the Suitable, Good and Strong machine for you

| Our machine delivery |

Friends, welcome contact us