|

Production Flow

The entire process can be summarized into three main stages: Front End - Precision Preparation, Middle End - Precision Forming, and Back End - Precision Finishing & Inspection.

Front End: Precision Preparation

1. Log Debarking & Cutting: Hardwood logs are debarked and cut into standard-length segments.

2. Precision Veneer Peeling: The log segments are peeled on a precision lathe into extremely thin, consistent veneer ribbons (e.g., 0.5-0.6mm). This is the foundation of the entire process and demands extremely high accuracy from the lathe.

3. Veneer Drying: The wet veneer is passed through a dryer to precisely reduce its moisture content to 8%-12%, while preventing deformation and cracking.

4. Veneer Clipping & Sorting: The dried veneer is clipped to set dimensions and automatically sorted by quality grade using a vision system.

Middle End: Precision Forming

5. Veneer Splicing & Patching: Narrow or defective veneer sheets are joined into full-size sheets using a splicing machine, significantly improving material utilization.

6. Precision Micro-Gluing: A thin, uniform layer of adhesive is applied to the ultra-thin veneer. The amount of glue must be precisely controlled.

7. Robotic Layup: Robots or high-precision laying equipment accurately assemble the glued and unglued veneers in a cross-oriented pattern (grains perpendicular) to form a mat. This is key to preventing product warping.

8. Continuous Pressing: The mat enters a continuous press where the adhesive is cured under high temperature and pressure, firmly bonding the veneers into a solid panel. This step directly determines the panel's thickness tolerance, flatness, and mechanical strength.

Back End: Precision Finishing & Inspection

9. Panel Cooling & Curing: The pressed panels are cooled to set their shape and then stored to allow internal stresses to equilibrate.

10. High-Precision Calibration Sanding: The panel surface is finely sanded to ensure precise, consistent thickness and a smooth, flat surface across the entire board.

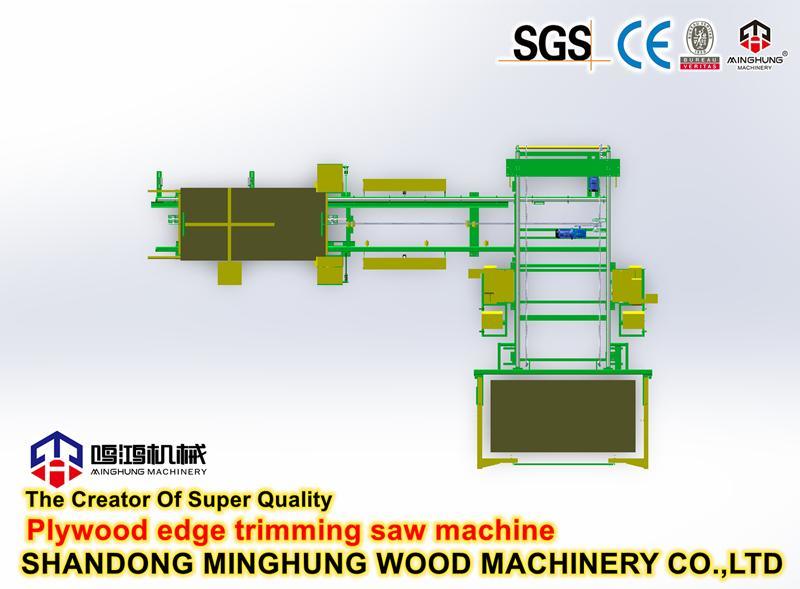

11. Precision Trimming & Cutting: The sanded panels are trimmed to the required final dimensions, with smooth edges free of chips.

12. Online Inspection & Packaging: Finished panels undergo automated inspection for thickness, appearance, and defects. They are graded, then filmed and packaged to prevent scratching.

|

Equipment List

Front End Equipment:

1. Drum/Ring Debarker: Efficiently removes bark.

2. Log Cutting Saw: Cuts logs to fixed lengths.

3. High-Precision CNC Veneer Lathe: One of the core machines of the production line. It requires high rigidity, high rotational speed, and micron-level feed accuracy to ensure the peeled ultra-thin veneer has uniform thickness and minimal lathe checks.

4. Mesh Belt Veneer Dryer: Equipped with precise temperature and humidity control systems for gentle and uniform drying of veneers.

5. Veneer Clipping Line & Vision Sorting System: Automatically clips and grades veneers by color and defects.

Middle End Equipment:

6. Automatic Veneer Splicing/Sewing Machine: Joins small veneer sheets into large full sheets.

7. Precision Four-Roller Glue Spreader: One of the core machines of the production line. Through the precise coordination of four rollers, it achieves ultra-thin, uniform adhesive application without missed spots or glue buildup.

8. Robotic/High-Precision Automatic Layup Line: Uses servo motors and visual positioning for accurate and efficient veneer layup.

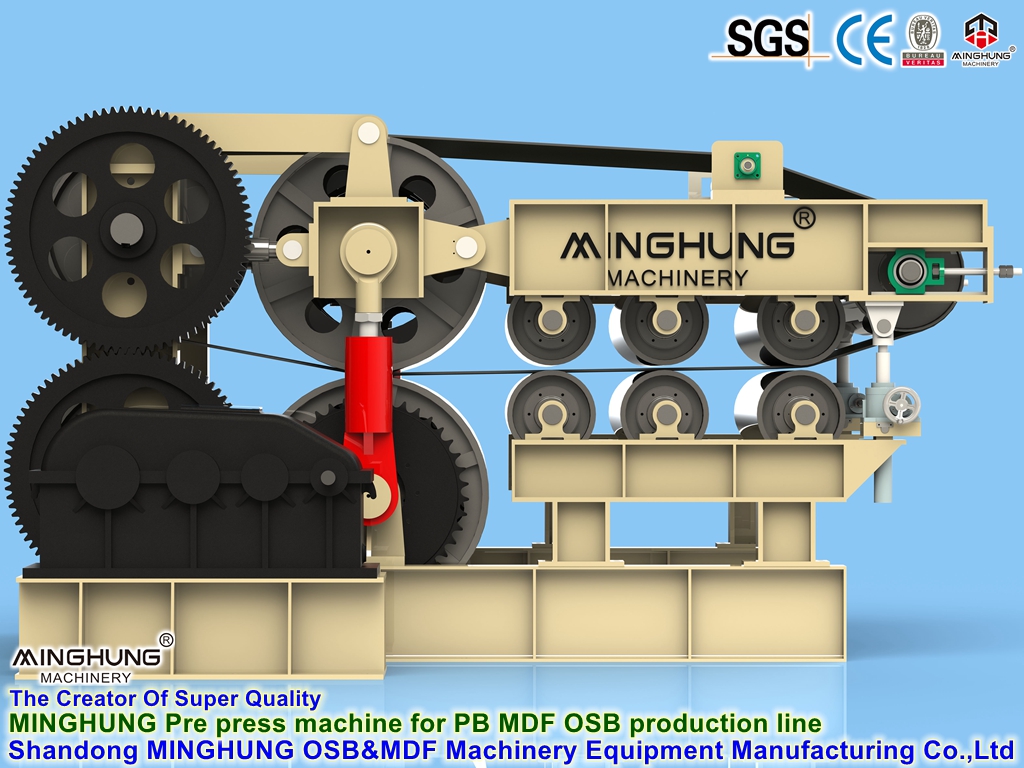

9. Continuous Press: The "heart" of the production line. It transports the mat via continuous steel belts, applying pressure and heat during movement. This results in extremely flat panels with minimal thickness variation, making it the key differentiator from ordinary multi-opening presses.

Back End Equipment:

10. Cooler/Stacker: Cools the panels uniformly for setting.

11. Multi-Head High-Precision Calibrating Sander: Typically with a three or four-head configuration, the final head being a high-grit fine sander for achieving a perfect surface.

12. CNC Trimming & Cross-Cutting Saws: Use special alloy saw blades or laser cutting to ensure smooth, burr-free cut edges.

13. Online Automatic Inspection & Packaging System: Includes laser thickness gauges, vision inspection cameras, and automatic filming and packing machines.

This production line is a highly integrated system of mechanical, electrical, hydraulic, sensing, and computer control technologies. Its value lies not only in the performance of individual equipment but also in the synergy and stability of the entire system, ensuring the continuous production of high-value-added ultra-thin plywood products.

|

Characteristics

1. Extreme Precision and Stability

Micron-Level Control: The entire process, from veneer peeling to final sanding, involves micron-level precision control, ensuring final product thickness tolerance can be consistently maintained within ±0.1mm.

High Structural Symmetry: Requires highly uniform thickness and moisture content for each veneer layer, strictly adhering to the symmetrical principle during layup to fundamentally prevent warping of ultra-thin panels.

Stable Dynamic Production: The line possesses high mechanical stability and anti-interference capability, ensuring long-term precision maintenance during continuous operation and eliminating quality fluctuations.

2. Intelligent Handling Capability for Ultra-Thin Materials

Gentle Handling System: For extremely thin veneers (0.3-0.8mm), conveying and transfer systems use technologies like vacuum adsorption and low-tension drives to effectively prevent tearing, wrinkling, and stretching during processing.

Intelligent Vision Recognition: High-resolution vision systems are widely used for automatic defect detection (e.g., splits, holes) in veneers and precise alignment during layup, ensuring raw material quality and assembly accuracy.

3. Precision Gluing and Control Technology

Micro-Dosing Glue Application: Utilizes a Precision Four-Roller Glue Spreader to achieve uniform, void-free application of an ultra-thin glue layer (0.05-0.1mm), perfectly balancing bond strength and avoiding "bleed-through" that stains the surface.

Accurate Temperature & Pressure Control: The hot press employs multi-zone temperature and pressure control, with temperature variations within ±2°C. Pressure profiles are optimized through precise simulation, ensuring complete and uniform adhesive curing within the ultra-thin structure.

4. High Automation and Intelligence

Robotic Core Processes: Industrial robots are commonly used in core processes like layup and handling, eliminating human error and ensuring production rhythm and quality consistency.

Centralized Intelligent Control: A central control system (PLC/Industrial PC) integrates all equipment parameters, enabling one-touch start/stop, recipe management, fault diagnosis, and data traceability, significantly improving management efficiency.

5. Advanced Forming Technology (Core Process)

Continuous Pressing Technology: The Continuous Press is universally adopted as the core. It applies shock-free, linear pressure via continuous steel belts, completely eliminating mat displacement and thickness variation caused by the "opening-closing" cycle of traditional multi-opening presses. This is the key to achieving the superior flatness and uniform thickness of ultra-thin panels.

6. Flexibility for High-Value-Added Products

Wide Raw Material Adaptability: The optimized line can efficiently process mixed hardwoods (e.g., poplar, eucalyptus, birch) and adapt to minor variations in veneer thickness.

Quick Changeover Capability: The central control system allows for rapid calling of production parameters for different products (e.g., thickness, size, adhesive type), enabling flexible production for small-batch, multi-specification orders.

7. Excellent Energy Efficiency and Quality Assurance

Energy-Saving Design: Core equipment like the continuous press and efficient drying systems are often equipped with heat recovery systems, significantly reducing energy consumption per unit product.

Full-Process Quality Monitoring: Integrated online thickness gauges and defect detection systems enable 100% real-time quality monitoring and automatic grading, ensuring "zero-defect" products upon shipment.

|

Application Fields

The ultra-thin precision plywood produced by this line serves as a core material in high-end industrial sectors:

Electronics Industry: Used as substrate for PCB test beds, packaging trays for electronic components.

Aviation & High-Speed Rail: Cabin interior panels, luggage bins, partitions, requiring ultimate lightweight and flame-retardant properties.

High-End Furniture: Back panels, drawer bottoms, substrate for curved components in premium furniture.

Crafts & Models: Precision laser cutting for models, toys, and crafts.

Lightweight Packaging: High-end gift boxes, instrument and equipment packaging liners.

|

Company Profile

We are Shandong MINGHUNG Wood Based Panel Machinery Co.,Ltd China factory and manufacturer of full sets of Plywood machinery and Veneer machinery. With many years production experience, advanced production technology,experienced workers and professional engineers, we can offer you the suitable, good and strong machinery for you.

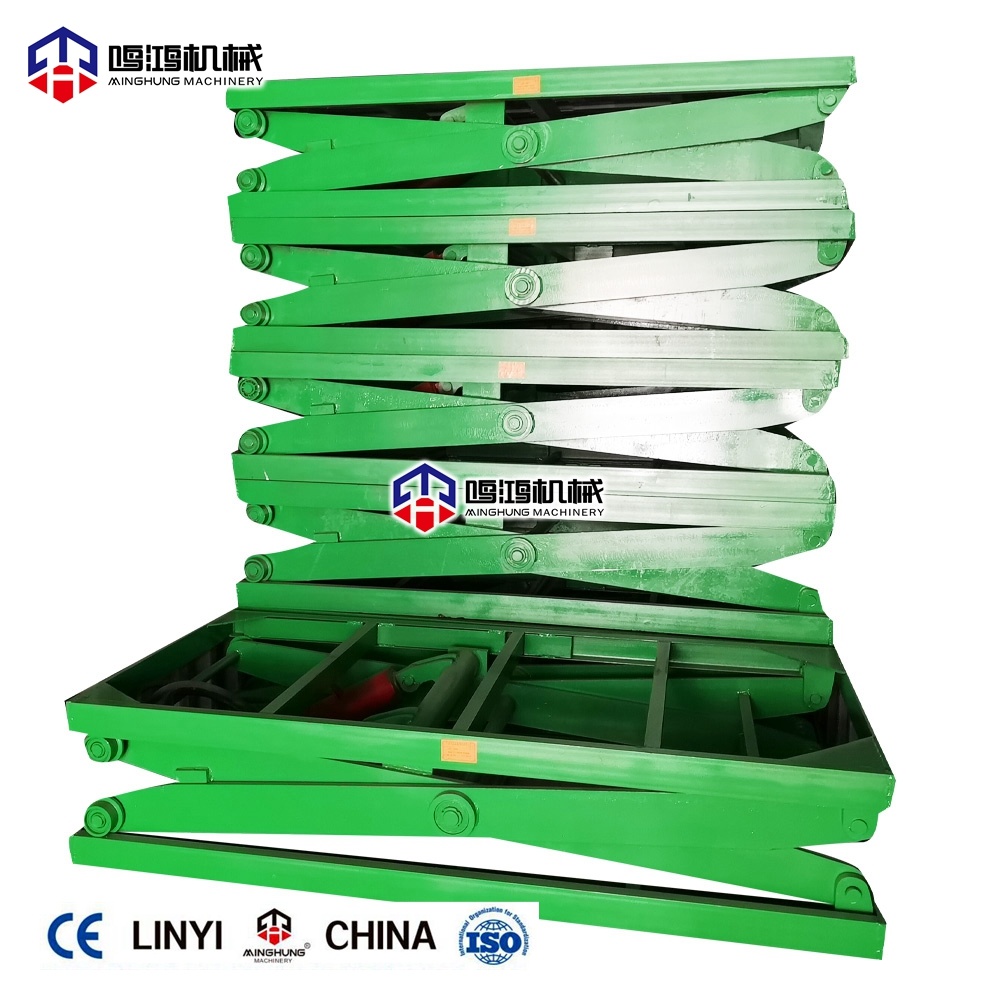

The machinery we produce includes peeling machines, chipping machines, rotary cutting machines, drying machines, gluing mixers, laying machines, pre-pressing machines, hot pressing machines, cooling machines, longitudinal and transverse sawing machines, sanding machines, as well as auxiliary machinery such as automatic feeding and discharging systems and lifting platforms.

|

Photos of shipping

|

Optional Surface

|

Why choose us?

1.100% customer-oriented solutions.

2.Team members with 40+ years of experience in the wood industry.

3.The strongest awareness of protecting customer business privacy.

4.Deep insight and understanding of market mysteries.

5.Familiar with international terminology.

6.Attention to details and integrity make us grow.