What is LVL sheet

LVL laminated veneer lumber (Laminated Veneer Lumber,) is a material formed by laminating thick veneers along the direction of the grain, hot pressing and gluing, and then sawing. can make up

Artificial fast-growing wood has shortcomings such as soft material, low strength, and large size variability, so as to realize the optimal use of inferior wood and the large use of small wood, and alleviate the conflict caused by the shortage of wood.

Process principle: LVL (Laminated Veneer Lumber) is a material formed by laminating thick veneers along the grain direction, hot pressing and gluing, and then sawing. It is similar to the production process of plywood

Recently, the veneer preparation process is almost the same, and the main difference lies in the blank formation, hot pressing and post-processing processes.

1. Rotary cutting board The raw wood is cut into veneers with different specifications and a thickness of 1-3 mm.

2. Drying and drying The veneers cut into various specifications are dried in the air, and then leveled and dried by a drying machine at about 120 degrees. The moisture content of the veneers is controlled at 8%-10%.

3. Splicing board The veneers that have been leveled by various ovens are spliced into a certain length of wide-band veneer through the inclined arcade machine according to the requirements of the production products.

4. Glue coating The veneer after drying and leveling the inclined street is glued by a glue coating machine. The glue is phenolic glue, and the formaldehyde content does not exceed 1mg.

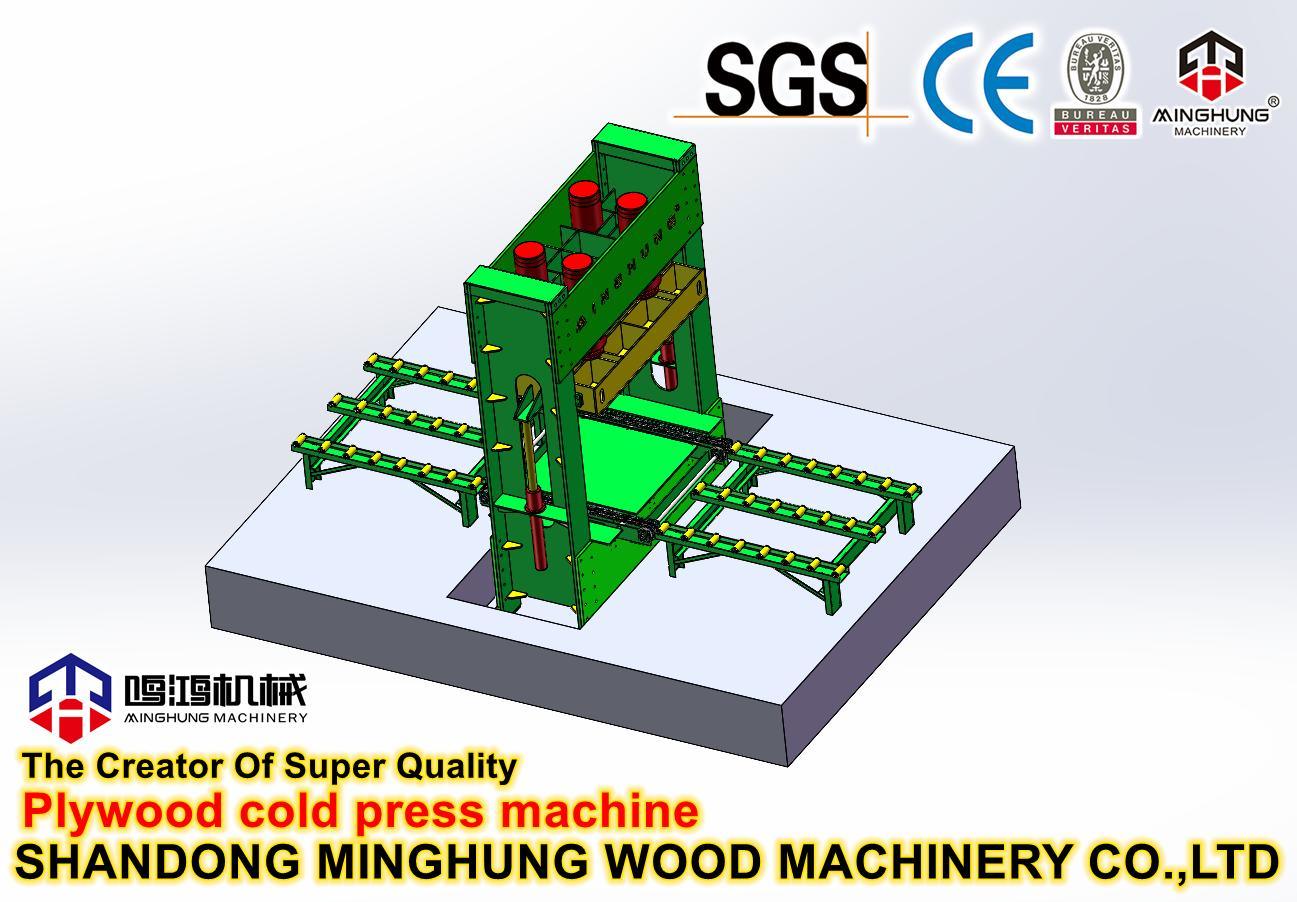

5. Laying board cold pressing According to the product requirements, the glued veneer is laid into a certain number of layers parallel to the direction of the wood grain, and formed by cold pressing.

6. Hot pressing The cold-pressed laminated board is hot-pressed at a temperature of 160 degrees Celsius for a certain period of time through a 1500-ton hot press, and the glue is heated and cured to form a laminated board.

material.Whatsapp: +8618769900191 +8615589105786 +8615805493072

Email: minghungmachinery@gmail.com

Website: www.plywoodmachineline.com