1. Loading and Preparation

Logs (typically cut to a set length) are transported to the loading area of the peeler via infeed roller conveyors or auxiliary equipment like forklifts.

The operator selects or calls up the processing program for the corresponding wood species and target veneer thickness via the CNC system (HMI touchscreen).

2. Automatic Centering and Clamping

The loading mechanism (e.g., hydraulic pusher or chains) moves the log into the spindle area of the machine.

The Automatic Centering System activates: Detection devices (laser scanners or mechanical arms) located on both sides of the machine synchronize to detect the geometric center at each end of the log. The control system calculates and automatically adjusts the position of the Left and Right Spindle Heads (usually via servo-driven slides) to align the centerline of the spindles with the log's optimal practical rotation axis.

After centering, the hydraulically or servo-driven Spindle Chucks extend synchronously from both ends. Powerful clamping force drives the sharp chuck points into the log ends, achieving a firm grip.

3. High-Speed Peeling

The Main Drive Motor starts, rotating the clamped log at high speed via a gearbox or direct drive.

Simultaneously, the Tool Rest Assembly, driven by a Servo Motor and a High-Precision Ball Screw, feeds precisely and uniformly towards the rotating log according to the set veneer thickness.

The high-strength alloy Peeling Knife mounted on the Tool Rest contacts the wood surface at a constant clearance angle, continuously and evenly peeling the wood into a ribbon of veneer.

Throughout the process, the CNC system adjusts the spindle speed in real-time based on a preset "Constant Linear Speed" logic (increasing speed as the log diameter decreases), ensuring stable cutting conditions and consistent veneer quality.

4. Veneer Conveying and Handling

The peeled continuous veneer ribbon is smoothly drawn out from the knife gap due to the centrifugal force of the rotating log and the guidance from devices near the knife.

The veneer immediately enters the Rear Conveying System (typically a set of synchronously driven rollers or belts) and is transported smoothly to the next process (e.g., clipping, drying, or reeling).

Some high-end models are equipped with an Online Thickness Gauge to monitor veneer thickness in real-time and provide feedback to the control system for closed-loop accuracy correction.

5. Unloading and Reset

When the log is peeled down to a near-core minimum diameter (e.g., Φ60-80mm), the control system issues commands: the tool rest rapidly retracts, and the spindles stop rotating.

The spindle chucks retract, releasing the remaining wood core (peeler core).

The unloading mechanism ejects the core out of the machine via a chute below or to the side.

All moving components (spindle slides, tool rest) automatically return to their starting positions, ready for the next cycle.

1. Machine Bed and Base

The foundational structural component of the entire machine, usually fabricated from high-quality steel plates and stress-relieved. It features a box-type or frame structure with extremely high rigidity, vibration resistance, and stability, forming the cornerstone for long-term precision.

2. Spindle Clamping System

Left/Right Spindle Headstock: Houses high-precision spindle bearings, the core support for chuck rotation.

Hydraulic/Servo Spindle Chuck: Extends from the spindle end to clamp the log. The tip features multi-toothed grips to ensure powerful biting without slippage. Its extension/retraction and clamping force are precisely controlled by hydraulic cylinders or servo electric cylinders.

Spindle Slide and Drive: Moves the entire headstock along guide rails for centering. Driven by a servo motor, ensuring synchronized movement and precise positioning.

3. Cutting System

Tool Rest Assembly: Includes a robust tool rest body, the Peeling Knife (made of high-carbon high-chromium alloy tool steel or carbide inserts), the Pressure Bar (used to bend the wood ahead of the cutting point to reduce backside checks), and their adjustment mechanisms.

Tool Rest Feed Drive Unit: Its core consists of a Servo Motor, a Precision Ball Screw Assembly, and heavy-duty linear guides. It is responsible for executing thickness commands and driving the tool rest in precise linear motion.

4. CNC System and Electrical Cabinet

Core Controller: Typically an industrial PLC (e.g., Siemens, Mitsubishi) or a dedicated CNC controller, acting as the "brain".

Human-Machine Interface (HMI): High-resolution touchscreen for parameter setting, program management, status monitoring, and fault diagnosis.

Servo Drives and Motors: Control all precision axes, including spindle slide movement and tool rest feed.

Electrical Cabinet: Integrates all electrical components such as circuit breakers, contactors, frequency inverters (for main motor speed control), etc., featuring cooling and protection ratings.

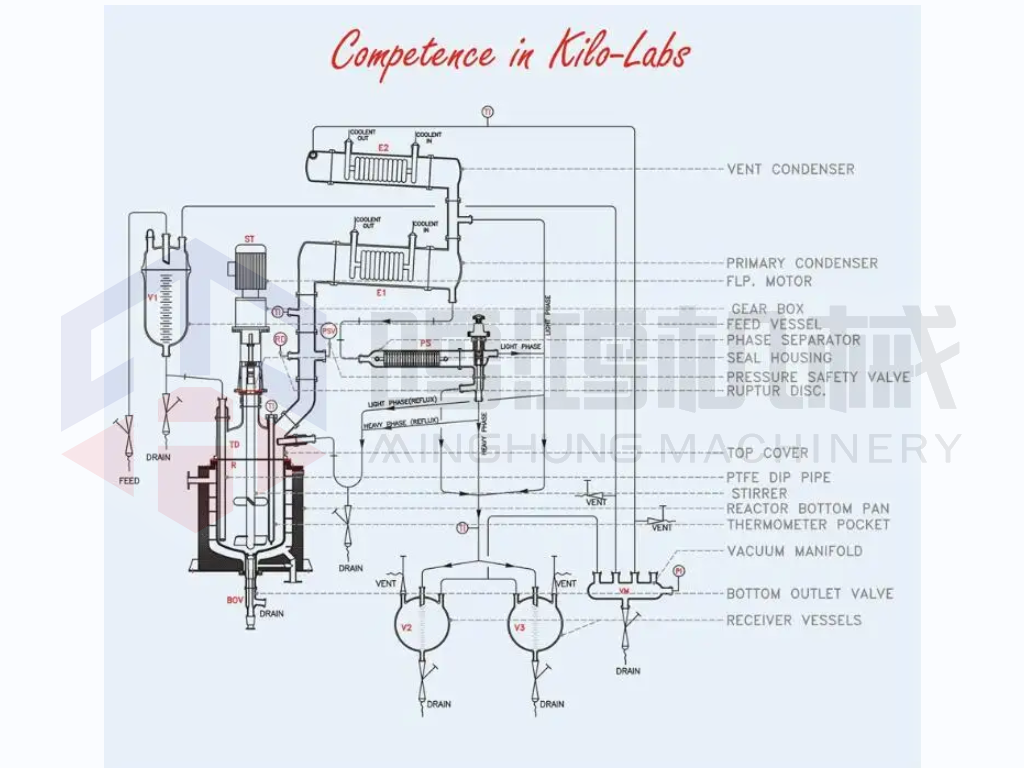

5. Hydraulic System (if hydraulic chucks/pressure bar are used)

Includes a hydraulic power unit (motor, pump), control valve blocks, cylinders, piping, and a cooler. Provides stable high-pressure oil supply required for actions like chuck clamping and lubrication.

6. Auxiliary and Detection Devices

Automatic Centering Detection Device: Laser sensors or mechanical probes, key to achieving high yield.

Rear Conveyor Rollers/Belt: Ensures flat transportation of the veneer.

Centralized Lubrication System: Automatically injects lubricant at timed intervals to key points like guide rails and ball screws.

Safety Guards and Devices: Include fully or partially enclosed guards, emergency stop buttons, light curtains, etc., ensuring operational safety.

High Speed & Efficiency: Peeling line speed can exceed 100m/min. Coupled with an automatic feeding system, production efficiency is significantly enhanced.

High Precision & Stability: The spindle structure offers excellent rigidity, ensuring consistent peeling thickness and high surface smoothness of the veneer.

Strong Adaptability: Capable of peeling a wide diameter range (typically φ150mm – φ800mm) and handles bent or irregular logs effectively.

Intelligent Operation: Digital setting of parameters like thickness, length, and speed. Process recipes can be recalled with one click, reducing reliance on operator experience.

Easy Maintenance: Major transmission components use branded standard parts, and the centralized lubrication system simplifies daily maintenance and reduces costs.

Typical Technical Specifications

Maximum Peeling Length: 2600mm / 2800mm / 3150mm

Log Diameter Range: φ150mm – φ800mm

Veneer Thickness Range: 0.5mm – 5.0mm (Customizable)

Spindle Speed: 50 -100 rpm (Stepless speed regulation)

Main Motor Power: 20kW – 50kW

Tool Rest Feed Drive: AC Servo Motor

Control Accuracy: Thickness error ≤ ±0.01mm

Total Installed Power: Approx. 55kW – 75kW

Who We Are ?

We are Shandong MINGHUNG Wood Based Panel Machinery Co.,Ltd China factory and manufacturer of full sets of Plywood machinery and Veneer machinery.

Machines include:Veneer production line(Log debaker,Veneer peeling machine, Log loader,Automatic stacker),Blade sharpener,Veneer patching machine,Veneer dryer machine(Veneer roller dryer, Veneer mesh dryer, Veneer press dryer), Veneer gluing machine,Plywood lay-up machine, Veneer jointing machine, Plywood cold press, Hot press machine,Plywood edge trimming cutting machine, Sanding and calibrating machine, Plywood overturn machine, Lift table, and so on.