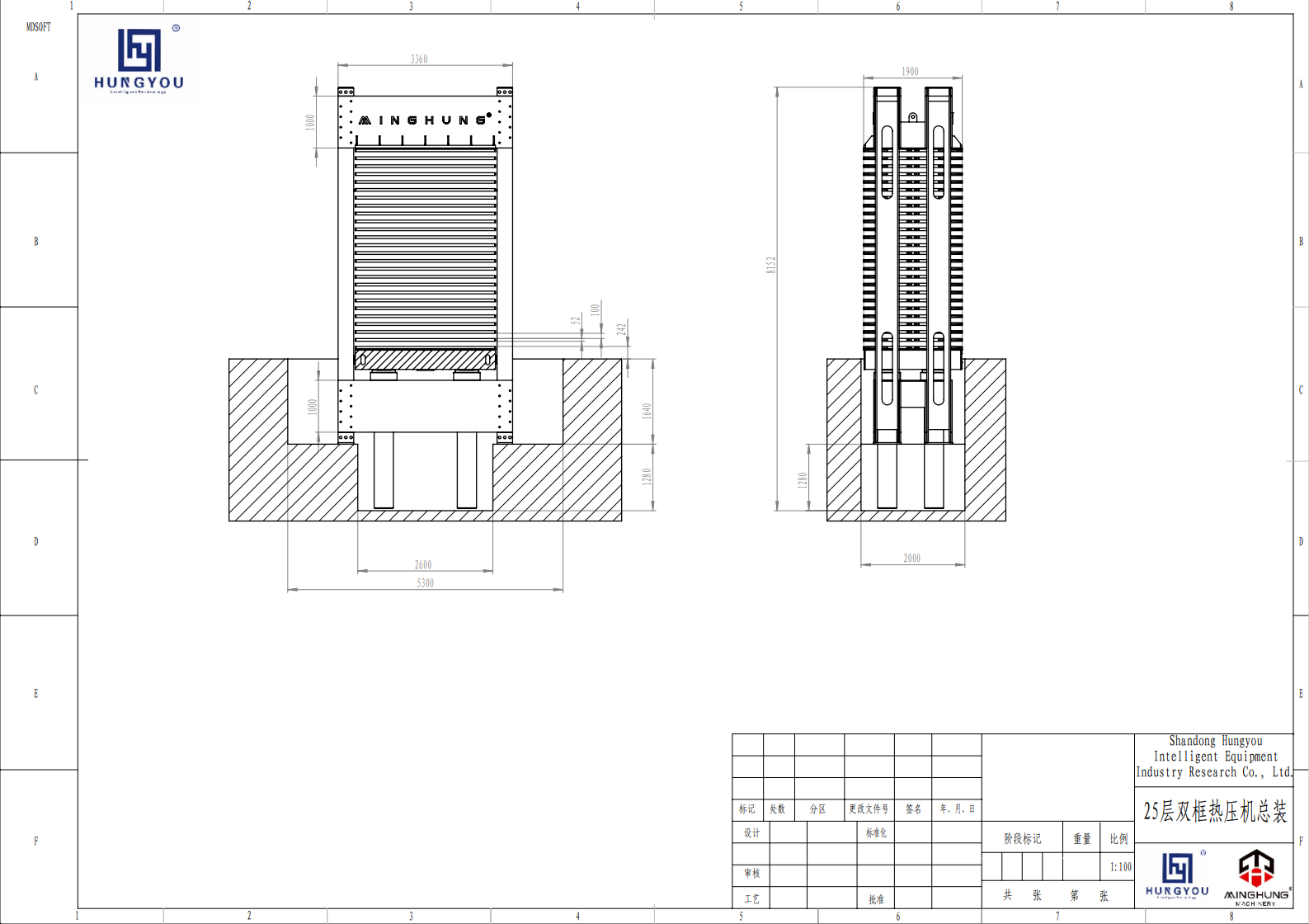

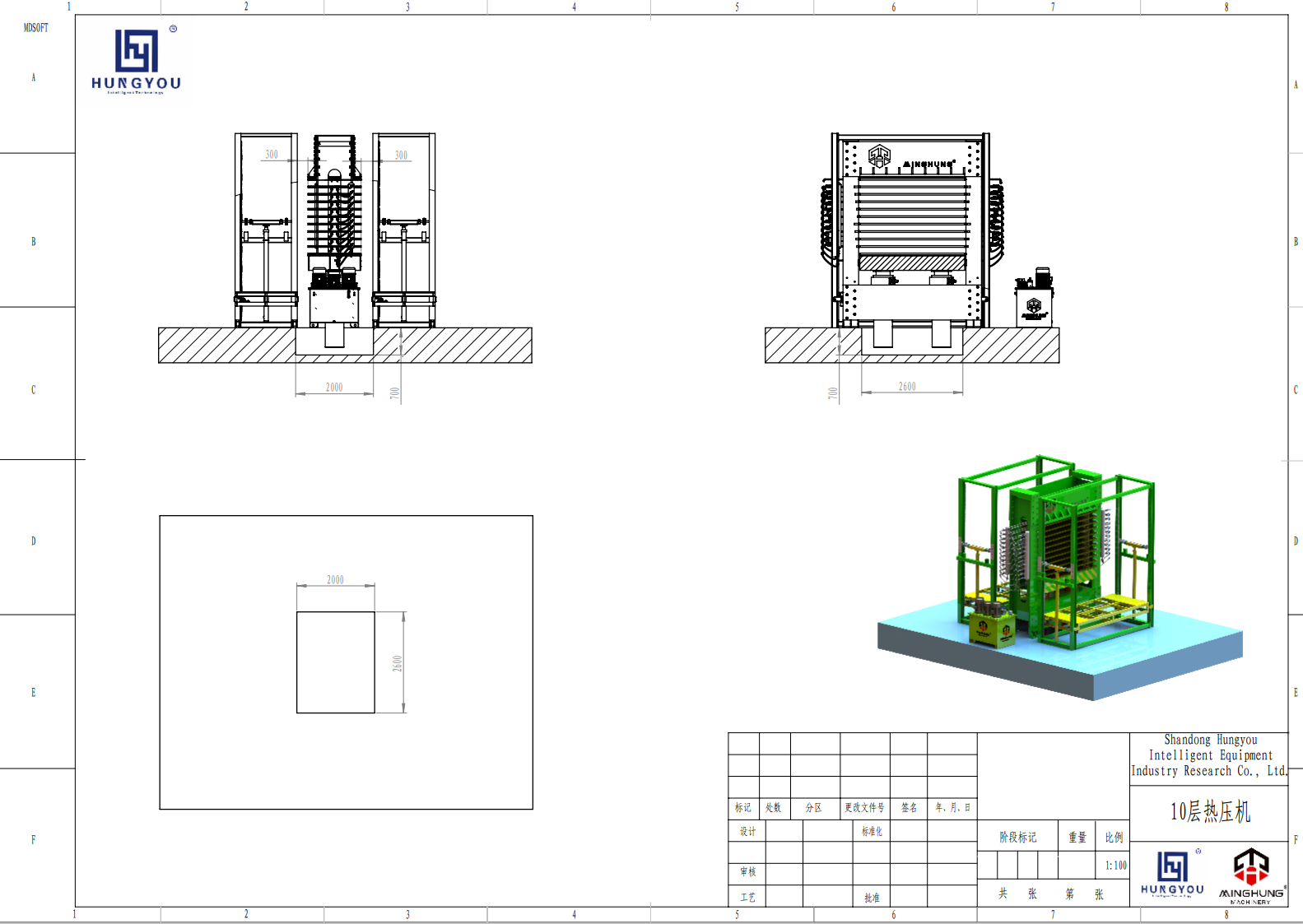

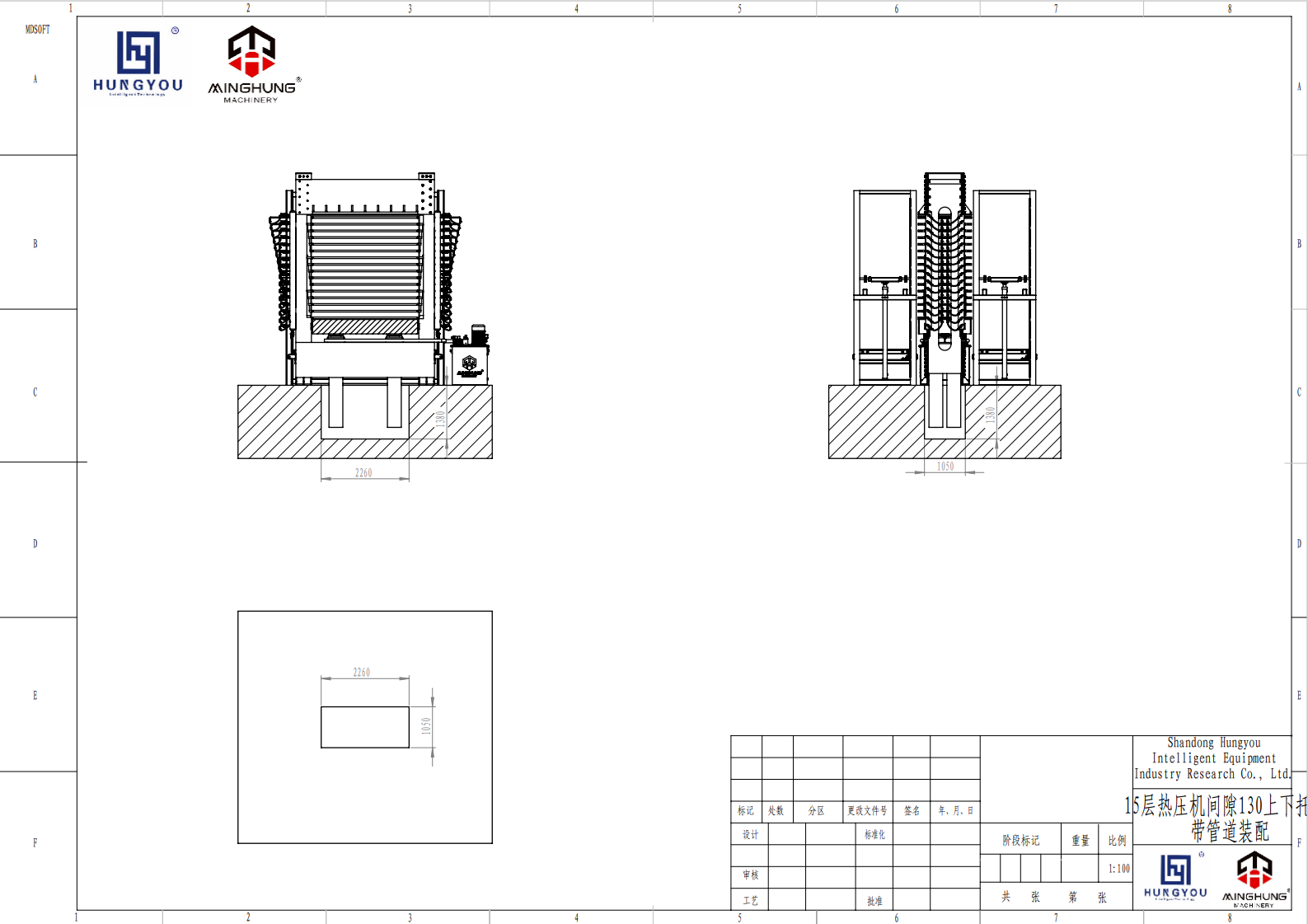

CNC Plywood Hot Press for Plywood Production Machine

Hot press production process

The slab is loaded into a hot press, and the adhesive is fully cured by heating to make a production process of plywood with high strength. Hot pressing is the most critical procedure in plywood production, which directly affects the strength and yield of plywood.

During the hot-pressing process, hot-pressing pressure, hot-pressing temperature, and hot-pressing cycle are key process parameters that affect product quality, and should be controlled from the following aspects:

1. Determination of hot-pressing temperature The hot-pressing temperature is mainly determined according to the type of adhesive, focusing on the temperature selection of urea-formaldehyde glue and phenolic resin, and the moisture content of the veneer should also be considered

2. Selection of hot pressing pressure If the hot pressing pressure is too high, the compression ratio of the slab will be too high, and the cost of raw materials will increase; if the pressure is too small, the strength of the plywood will decrease, which will affect the product quality. The pressure should be controlled within an appropriate range according to the process requirements, and the gauge pressure of the hot press should be calculated according to the unit pressure during operation

3. Determination of the hot-pressing cycle The hot-pressing cycle is mainly determined according to factors such as the thickness of the slab, the moisture content of the veneer, the type of glue, the hot-pressing temperature and the hot-pressing pressure. Experience, bulletin inspection of product quality to find out the heat press cycle parameters.

Whatsapp: +8618769900191 +8615589105786 +8615805493072

Email: minghungmachinery@gmail.com

Website: www.plywoodmachineline.com

>>>Specification:

>>>Advantages:

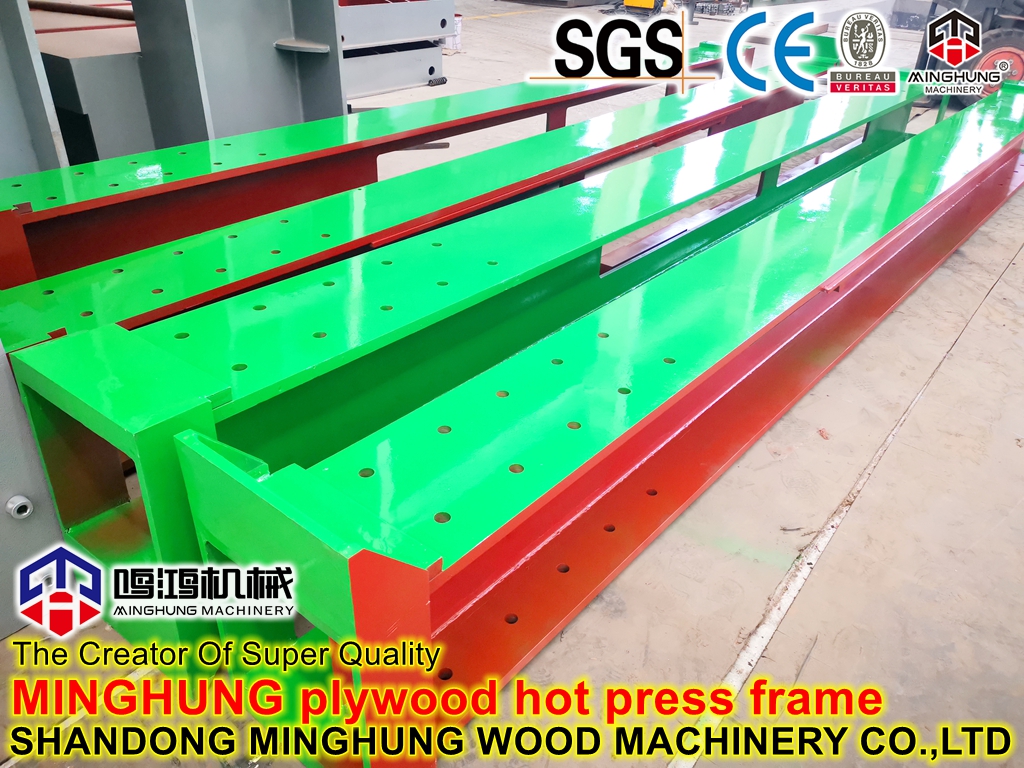

>>>Machine show

when machine reach your factory, our engineer will go to install machine, and teach your worker how to operate and maintain.

>>>Us

>>>Our friends:

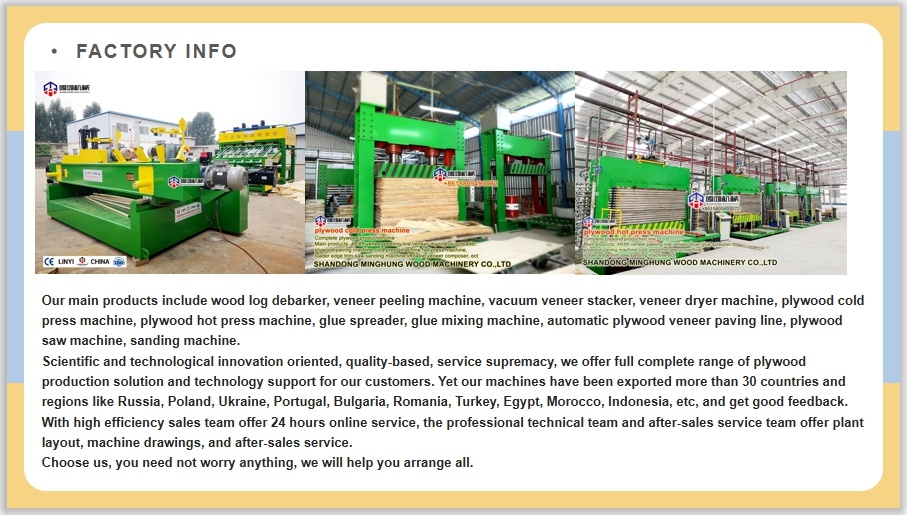

Our main products include wood log debarker, veneer peeling machine, vacuum veneer stacker, veneer dryer machine, plywood cold press machine, plywood hot press machine, glue spreader, glue mixing machine, automatic plywood veneer paving line, plywood saw machine, sanding machine.

Scientific and technological innovation oriented, quality-based, service supremacy, we offer full complete range of plywood production solution and technology support for our customers. Yet our machines have been exported more than 30 countries and regions like Russia, Poland, Ukraine, Portugal, Bulgaria, Romania, Turkey, Egypt, Morocco, Indonesia, etc, and get good feedback.

With high efficiency sales team offer 24 hours online service, the professional technical team and after-sales service team offer plant layout, machine drawings, and after-sales service.

Choose us, you need not worry anything, we will help you arrange all.

>>>Delivery:

1> When loading, we will share the loading pictures of plywood press machine with you.

2> When ship leave, we will offer the container and ship information for you.

3> Offer all documents which for your custom clearance.

>>>Related Plywood Machine:

we produce the full line of plywood machine.

wood debarker, veneer peeling machine, vacuum veneer stacker, veneer dryer machine include veneer press dryer and roller dryer, plywood cold press machine, plywood hot press machine, glue spreader, glue mixing machine, automatic plywood veneer paving line, plywood saw machine, sanding machine.

>>>Contact us:

Hot press production process

The slab is loaded into a hot press, and the adhesive is fully cured by heating to make a production process of plywood with high strength. Hot pressing is the most critical procedure in plywood production, which directly affects the strength and yield of plywood.

During the hot-pressing process, hot-pressing pressure, hot-pressing temperature, and hot-pressing cycle are key process parameters that affect product quality, and should be controlled from the following aspects:

1. Determination of hot-pressing temperature The hot-pressing temperature is mainly determined according to the type of adhesive, focusing on the temperature selection of urea-formaldehyde glue and phenolic resin, and the moisture content of the veneer should also be considered

2. Selection of hot pressing pressure If the hot pressing pressure is too high, the compression ratio of the slab will be too high, and the cost of raw materials will increase; if the pressure is too small, the strength of the plywood will decrease, which will affect the product quality. The pressure should be controlled within an appropriate range according to the process requirements, and the gauge pressure of the hot press should be calculated according to the unit pressure during operation

3. Determination of the hot-pressing cycle The hot-pressing cycle is mainly determined according to factors such as the thickness of the slab, the moisture content of the veneer, the type of glue, the hot-pressing temperature and the hot-pressing pressure. Experience, bulletin inspection of product quality to find out the heat press cycle parameters.

Whatsapp: +8618769900191 +8615589105786 +8615805493072

Email: minghungmachinery@gmail.com

Website: www.plywoodmachineline.com