Ⅰ.Plywood

Plywood is a composite wood panel made by bonding three or more thin wood veneers with adhesive under heat and pressure. The key principle is cross-grain lamination – alternating the wood grain direction of adjacent layers to neutralize internal stress and enhance stability.

Structural Features

Layered Structure: Odd number of layers (3/5/7+), high-grade veneer for surfaces, fast-growing wood for core.

Grain Orientation: Adjacent veneers perpendicular to each other (orthogonal stacking).

Symmetry: Matching veneer species, thickness, and moisture content on both sides of the core to prevent warping.

Key Advantages

✔ High Strength-to-Weight Ratio: Cross-lamination distributes load, outperforming solid wood.

✔ Dimensional Stability: Resists warping/cracking, adaptable to humidity changes.

✔ Material Efficiency: Compatible with lower-grade core wood, reducing raw material costs.

✔ Eco-Friendly: 50% less timber consumption vs. solid wood.

✔ Workability: Easy to cut, drill, and finish.

| Complete Production Process |

1. Log Processing: Debarking → Steaming → Rotary/Plain Slicing (producing 0.3–4mm veneers).

2. Veneer Drying: Kiln-drying to 8–12% moisture content (prevents glue failure/blistering).

3. Gluing & Layup:

Core veneer coated with resin (UF/PF) on both sides.

Manual/semi-auto layup (cross-grain alignment).

4. Pre-pressing: Cold pressing for initial bonding (prevents layer shifting).

5. Hot Pressing:

Temp: 120–180℃ | Pressure: 1.5–3.0 MPa

Duration: ≈1 min per mm thickness (e.g., 18min for 18mm board).

6. Trimming & Sanding:

Edge-cutting to standard sizes (e.g., 1220×2440mm).

Calibrated sanding (precision: ±0.1mm).

7. Grading & Packaging: Sorting (A/AA/AAA) → Labeling → Bundling.

| Application Scenarios |

Industry | Uses |

Construction | Concrete formwork, wall sheathing, scaffold decking |

Furniture | Cabinet carcass, tabletops, shelves |

Transportation | Truck flooring, ship bulkheads |

Packaging | Export pallets, heavy-duty crates |

Decoration | Substrate for veneer/HPL/metal foil |

| Cost-Effective Plywood Line Equipment |

1. Log Peeler & Rotary Lathe

Function:

Debarking → Steaming → Rotary-cutting logs into continuous veneer strips (thickness: 0.3–4mm adjustable).

Economy Configuration:

Hydraulic drive (non-servo motor), 30% power saving.

Standard alloy blades (tungsten carbide optional, 2x lifespan).

Specs:

Log diameter: Φ150–800mm

Peeling speed: 15–30m/min

Power: 22–45kW

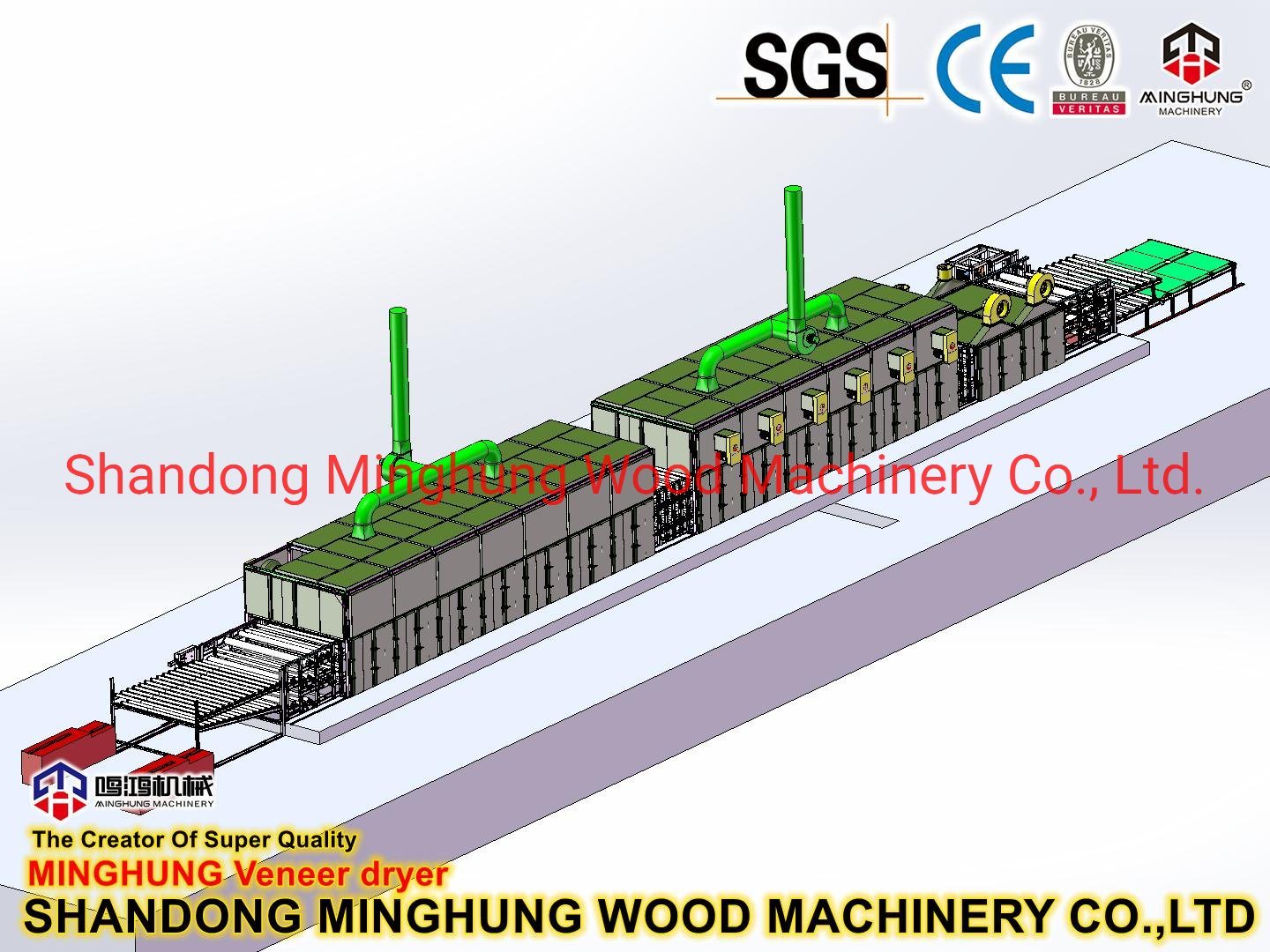

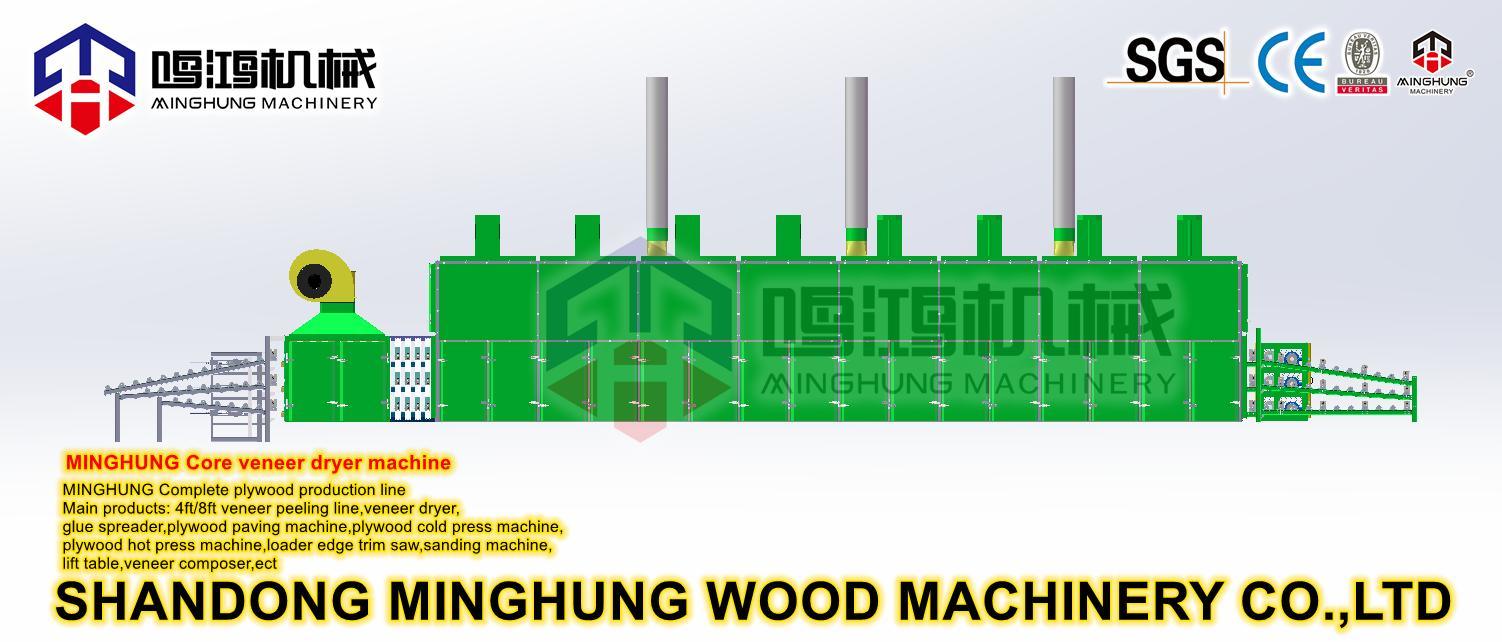

2. Veneer Dryer

Function:

Dries wet veneer to 8–12% moisture content (prevents delamination during hot pressing).

Economy Configuration:

Mesh-belt type (non-roller), heat source: coal/biomass.

Zoned temperature control (80–120℃), 20% energy saving.

Specs:

Capacity: 3–8m³/shift

Belt speed: 0.5–5m/min adjustable

Energy consumption: ≤120kWh/m³

3. Glue Spreader

Function:

Applies UF/PF resin evenly on both sides of core veneers.

Economy Configuration:

Double-roller coating (non-curtain type), glue spread accuracy: ±10g/m².

Heated glue tank (prevents gelation at low temps).

Specs:

Coating width: 1300–2500mm

Spread volume: 120–280g/m² (adjustable)

Power: 5.5kW

4. Manual Layup Station

Function:

Workers assemble glued veneers in cross-grain alignment.

Economy Configuration:

Scale-positioning baffles → Improve alignment accuracy.

Vacuum suction cups assist handling (reduces labor intensity).

Efficiency:

Manual layup: 3–5 mins/sheet (1220×2440mm).

5. Pre-press

Function:

Cold pressing (0.8–1.2MPa) for initial bonding, prevents layer shifting in hot press.

Economy Configuration:

Frame structure (non-four-column), pressure uniformity ≥85%.

Auto timer for pressing (2–5 mins).

Specs:

Platen size: 1300×2500mm

Max pressure: 200 tons

6. Multi-opening Hot Press

Function:

Cures adhesive under high heat/pressure (core equipment).

Economy Configuration:

8–12 openings (SME standard, daylight: 120mm).

Steam/thermal oil heating (biomass boiler compatible).

PLC auto-control (±2℃/±0.1MPa).

Specs:

Press size: 1300×2500mm

Max temperature: 180℃

Max pressure: 3000psi

Closing speed: ≥30mm/s

7. Trimming Saw

Function:

Cuts rough-edged panels to standard sizes (e.g., 1220×2440mm).

Economy Configuration:

Crosscut + rip saw combo.

Pneumatic hold-down rollers (cutting accuracy ±0.5mm).

Specs:

Blade diameter: Φ350mm (carbide teeth)

Feed speed: 10–30m/min

8. Wide Belt Sander

Function:

Calibrates thickness & surface sanding (Ra≤3.2μm).

Economy Configuration:

3-sand head (coarse + fine + polish).

Pneumatic pressure pads (adapts to uneven surfaces).

Specs:

Sanding width: 1350mm

Removal capacity: 0.1–1.5mm/pass

Accuracy: ±0.1mm

Economy Solutions:

Semi-automated layup (labor-assisted cost reduction)

8–12 opening hot press (mid-small capacity)

Optional biomass heating (30% energy savings)

The production line can be arranged in a U-shaped layout (reducing the transportation distance by 30%), and the hot press machine is placed in the center (shortening the path of the hot plate transportation).

| Small/Medium Production Line Scale |

Output: 30–150 sheets/day (1220×2440mm standard)

Factory Requirements:

Area: 800–1500m² (incl. raw material storage)

Clear Height: ≥6m (for hot press operation)

Request a Quote Today! OEM/ODM solutions available – Start your plywood business with competitive edge!

Our contacts:

Whatsapp: +8618769900191 +8615589105786 +8618954906501

Email: osbmdfmachinery@gmail.com