|

Required Mechanical Equipment

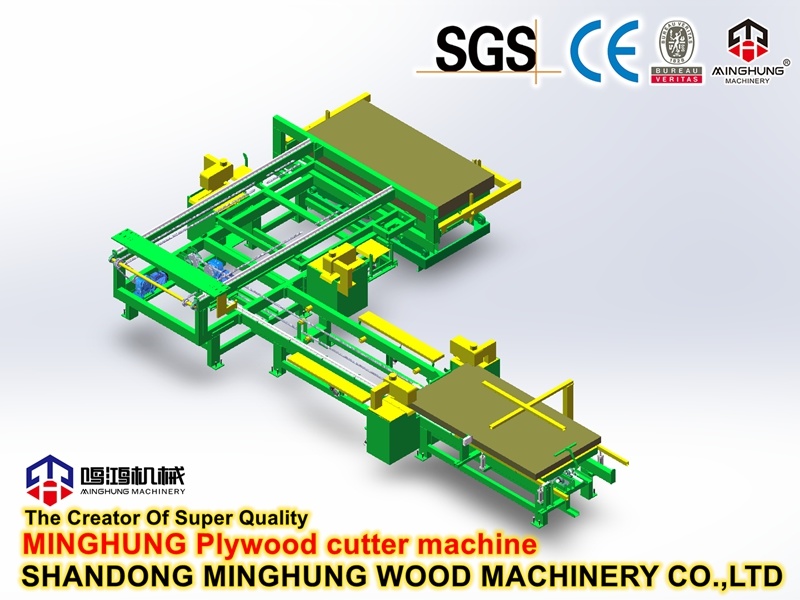

A complete non-standard size customized plywood cutting production line consists of the following core equipment, forming an automated work cell:

1. Automatic Loading System: Typically comprises a vacuum suction cup gantry or robotic arm for automatically and unmanned loading entire stacks of standard-sized base panels onto the production line.

2. CNC Cutting Center: The core brain of the production line. Usually refers to a CNC Panel Saw or High-Speed Processing Center. It receives design files and precisely controls the saw blade or router bit via servo systems to perform cuts of any shape and size on the X, Y, and Z axes.

3. Optimization Nesting Software System: This is not hardware but is crucial. The software automatically nests the required parts from customer orders onto standard large panels, calculates the most material-saving cutting layout, and generates CNC code instructions.

4. Automatic Marking System: Can print codes or labels on the cut panels to mark information like order numbers, part numbers, and dimensions, facilitating subsequent sorting and assembly.

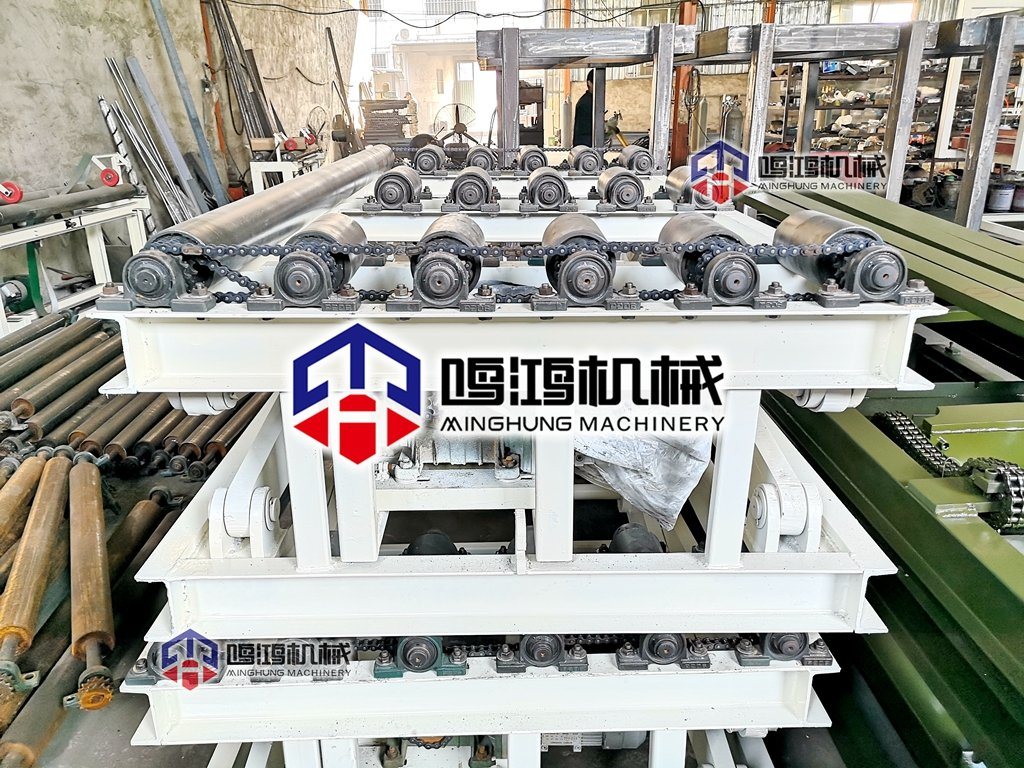

5. Sorting and Stacking System: After cutting is completed, panels of different sizes and orders are sorted and stacked via robots, conveyors with pusher devices, or with manual assistance.

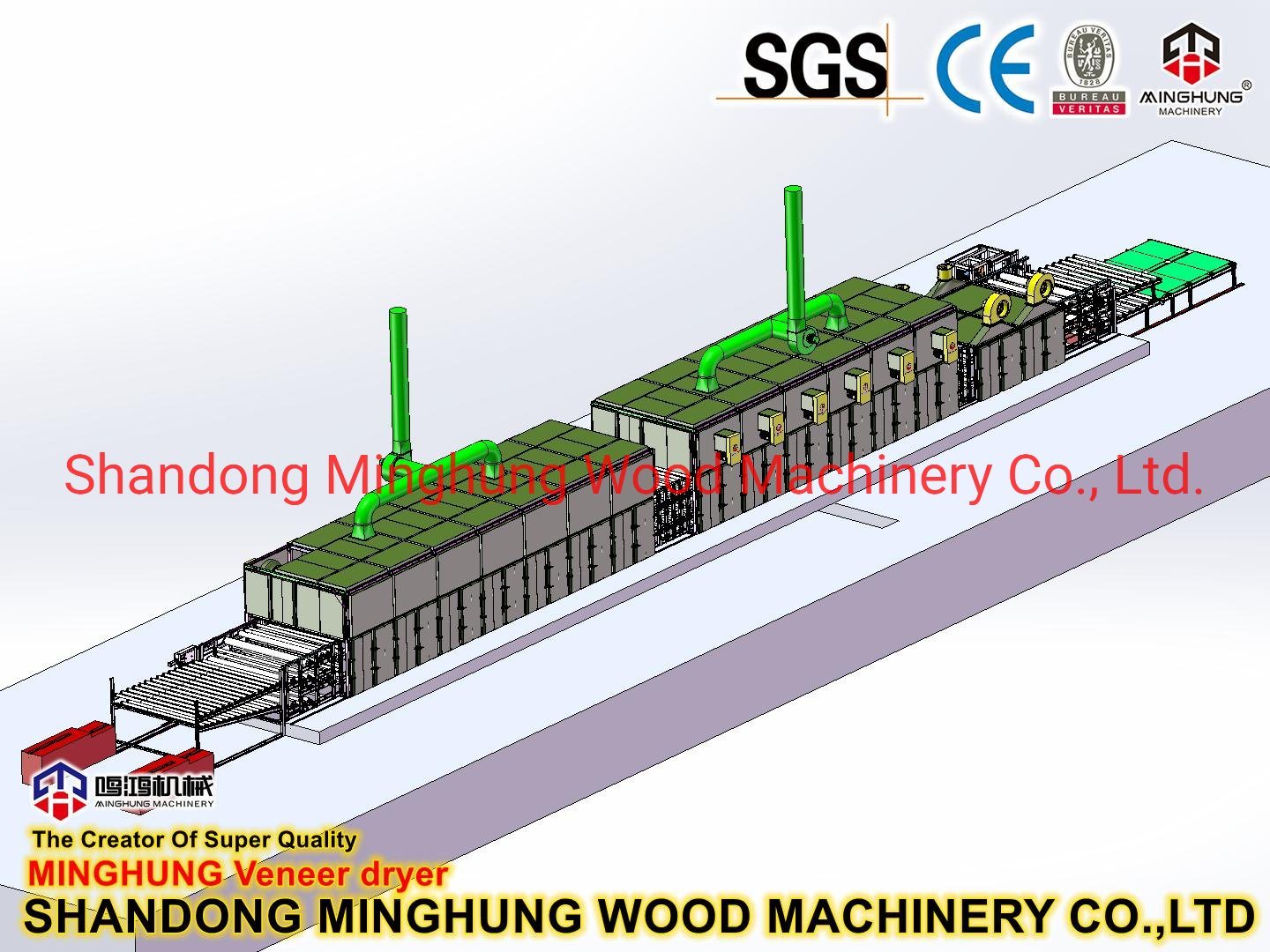

6. Centralized Dust Removal System: Connects to all dust-generating equipment to collect sawdust and debris, maintaining a clean workshop environment and ensuring equipment precision and worker health.

7. Control System: An integrated PLC master control system that coordinates all equipment to operate according to predefined programs and sequences, enabling full-line automation.

|

Production Process

1. Order Input: Input data such as customer-required non-standard sizes, quantities, and material types into the optimization nesting software.

2. Intelligent Optimized Nesting: The software automatically arranges thousands of small-sized parts onto standard large raw material panels, striving for the highest material utilization rate (can exceed 95%), and generates the optimal cutting path program.

3. Automatic Loading: The automatic loader picks up a full-size standard panel from the raw material storage and accurately places it onto the worktable of the CNC cutting center.

4. Precision Cutting: The CNC cutting center executes all transverse, longitudinal, and shaped cuts according to the program instructions. Vacuum pressing devices ensure the panel remains stable and does not shift during cutting.

5. Marking and Sorting: After cutting is complete, the marking system labels the panels. Then, the automatic sorting system or workers, guided by the software instructions, stack the panels from different orders into designated buffer areas.

6. Packing and Shipping: Panels for the same order are checked, packaged, and prepared for shipment.

|

Differences from Producting Standard Size Plywood

Feature | Non-Standard Size Custom Cutting Line | Standard Size Plywood Production Line |

Production Goal | Meets personalized, fragmented order demands | Mass produces uniform specification products |

Flexibility | Extremely High. Seamlessly switches between different size and shape cutting plans, adaptable to small-batch, high-mix production. | Very Low. Equipment (e.g., cross-cut and rip saws) has fixed settings. Changing sizes requires downtime for mechanical adjustment, which is time-consuming and laborious. |

Core Technology | Intelligent Optimization Nesting Software and CNC Cutting Center, emphasizing the value of data and algorithms. | Mechanical Dimensional Systems, emphasizing equipment stability and speed. |

Material Utilization | High (typically >90%). Minimizes waste through optimized nesting. | Relatively Low. Fixed-size cutting generates fixed leftover margins that cannot be used, and mixed nesting for different orders is impossible. |

Human Involvement | Low. Mainly for monitoring equipment, assisting with sorting, loading, and unloading. High degree of automation. | High. Requires manual measuring, adjusting fences, handling, and operating saws. |

Value Proposition | Provides solutions, helping customers save material, time, and labor costs, enabling flexible manufacturing. | Provides standardized products, pursuing output and cost advantages for single specifications. |

|

Applications

Architectural Decoration: Special-shaped wall panels for hotel lobbies, curved ceilings, customized building formwork.

Furniture Manufacturing: High-end custom furniture (e.g., multi-hole shelves), non-standard cabinet doors.

Transportation: Interior panels for yachts, RV floors, partition panels for high-speed train luggage compartments.

Industrial Design: Model boards for aerospace, exhibition props, substrate for art installations.

|

Core Advantages

We provide production line planning, factory layout design, and trial production services. Optional equipment modules include: automatic packaging lines, barcode traceability systems, and MES (Manufacturing Execution System) interfaces. Our cooperative case cover markets in Europe, Southeast Asia, and North America.