Film faced plywood pressing/melamine hot pressing veneer machine

Film faced plywood pressing/melamine hot pressing veneer machine is suitable for medium-sized furniture factory or small wood-based panel secondary processing (professional veneer) factory, used for heat-pressing bonding furniture panels, wooden doors (ie thin wood-based panels and inner frame gluing) ) and a variety of wood-based panels: such as plywood, blockboard, MDF, particleboard surface lamination of various materials: decorative paper, decorative cloth, melamine fireproof board, metal moor, artificial and natural veneer, natural veneer parquet. It can also be used for drying and leveling of veneer, leveling and shaping of colored decorative wood chips.

contact us: +8618769900191 +8615589105786 +8615805493072

website: www.plywoodmachineline.com

email: minghungmachinery@gmail.com

Film laminating hot press machine is one necessary machinery for making film faced plywood, anti-slip plywood, honeycomb plywood.

Film laminating hot press machine is one necessary machinery for making film faced plywood, anti-slip plywood, honeycomb plywood.

Its working way is: Workers just put the film and flat plywood on the semi auto infeeder's platform, then it will automatically convey the film plywood to each infeeder layers, and the auto infeeder will convey all film plywood into hot press machine, after pressing a while by high pressure, the film will fixed on the plywood.

Consider the film features, usually we advised that the film hot press at most 10 layers, it is more suitable. Also you can choose it be less like 8 layers, 6 layers, 5 layers

In general, film hot press will works together with its own semi auto infeeder, thus you can laminating film on both plywood sides at the same time, save time and improve work efficiency.

10 layers film hot press machine

Film press

Film faced plywood hot press machine

Laminating hot press with semi-auto infeeder

Building template plywood machine building template press machine

Building template plywood has high strength and hardness, acid and alkali resistance, corrosion resistance, no deformation, no formaldehyde, easy recycling, and can be made into various cross-sectional shapes and sizes, which not only retains the advantages of wood in processing performance, but also It overcomes the shortcomings of traditional building templates that are not durable and afraid of insects, and is now becoming a new favorite in the international and domestic building materials market.

Definition: MINGHUNG PRESS FOR BUILDING TEMPLATE PLYWOOD Building formwork plywood is a plywood formed by cutting logs into large veneers along the direction of the annual rings, drying and gluing them, and then forming blanks and gluing them according to the principle that the wood grain directions of adjacent veneer layers are perpendicular to each other.

Specifications: Common specifications on the market are 1830mm×915mm×18mm

2440mm×1220mm×21mm 2440mm×1700mm×21mm

Uses: Forming and curing newly poured concrete to make it reach a certain strength to bear the self-weight of the temporary structure and can be removed as a model plate. The formwork system of the reinforced concrete structure consists of two parts, one is the formwork that forms the shape and design size of the concrete member; the other is the support system that ensures the formwork shape, size and spatial position.

304 stainless steel plate

This is stainless steel plate, it is necessary for film press. on each hot plates, it needs two pieces stainless steel plate.

It has glossy surface and matte surface

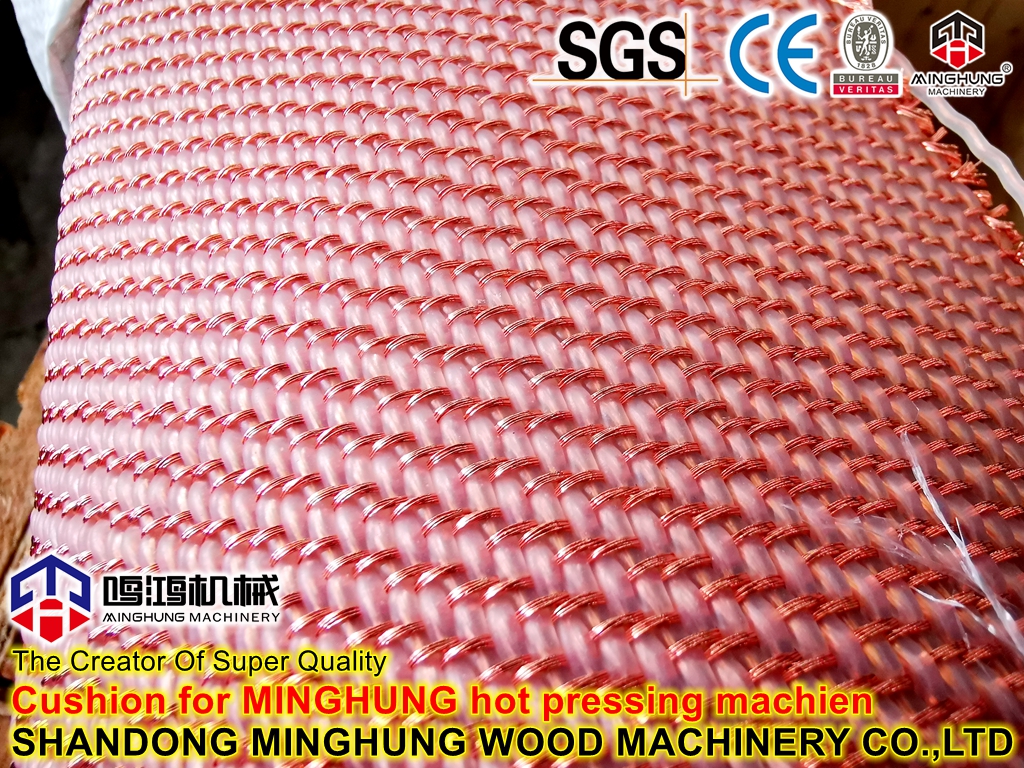

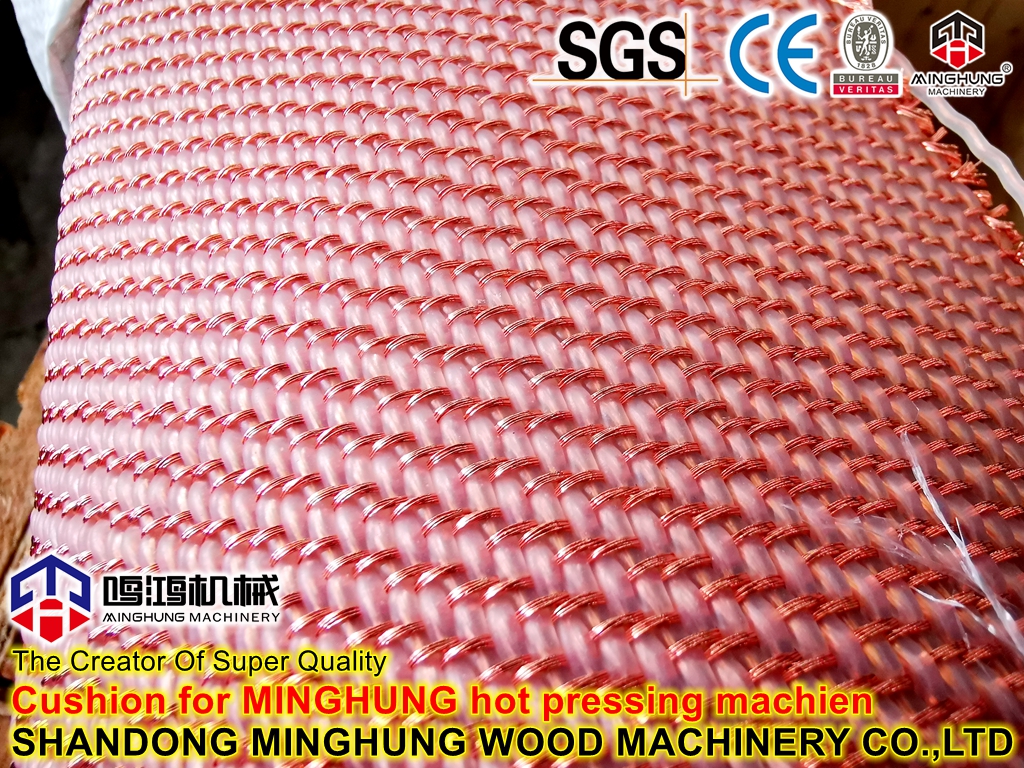

Cushion pad

This is cushion pad, it is necessary for film press too. on each hot plates, it needs two pieces cushion pad.

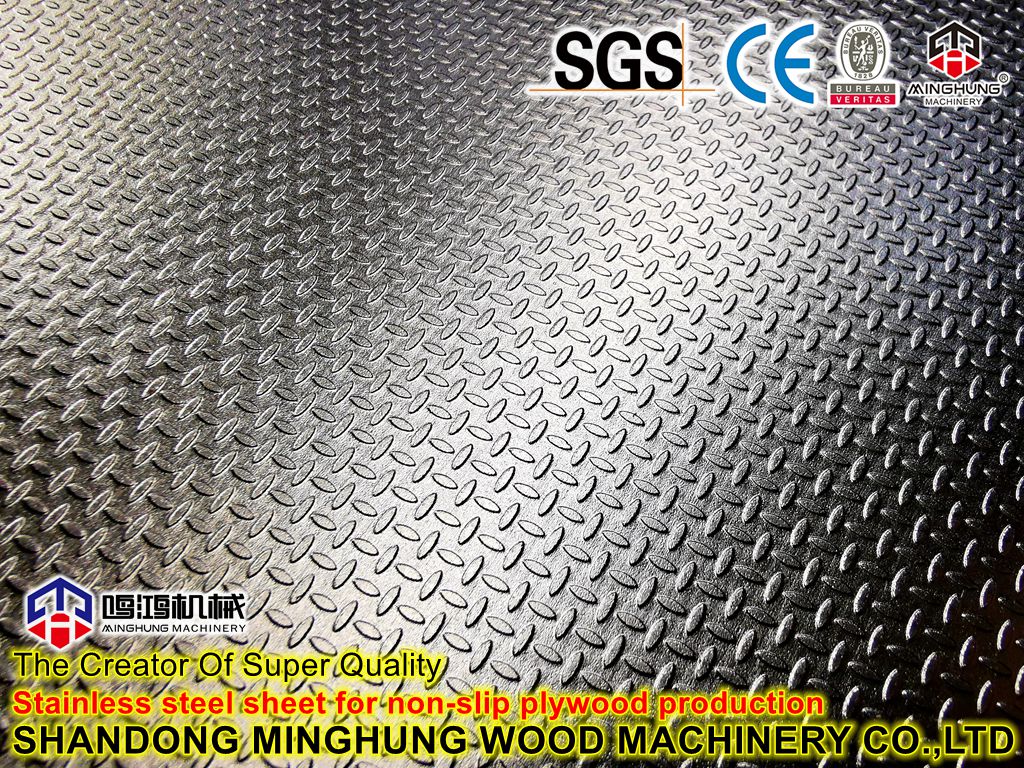

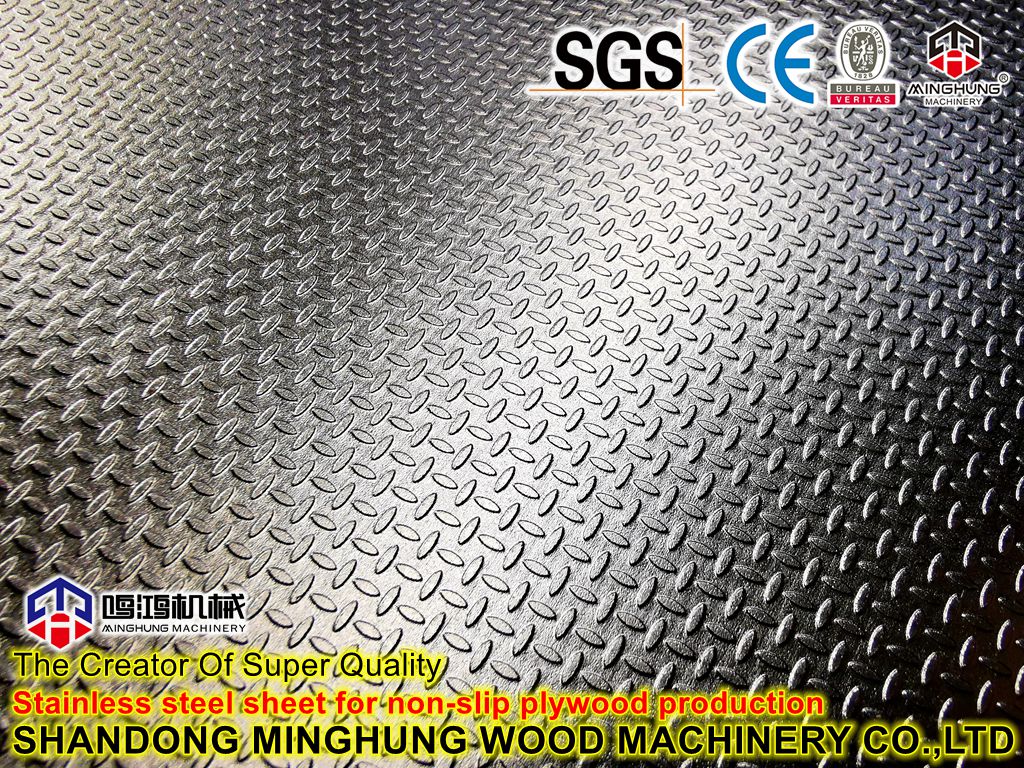

Honeycomb stainless steel plate

Millet stainless steel plate

Some clients produce anti-slip plywood, which plywood surface has pattern, thus the stainless steel plate will be different, it needs above type.

Flat film faced plywood

Hexagonal film faced plywood

For our film press machine, from its steel material, to the kinds of necessary spare parts and accessories, we use very good type, therefore, the whole our film press is very heavy, it can undertake high pressure. And all parts and accessories are good type, like Siemens engines, Schneider electric parts.

Electric box

Hydraulic station

Machine frame

Oil cylinder

| Name | Film press |

| Pressure | 800 ton |

| Cylinders | 6pcs *260mm dia |

| Daylights | 10 |

| Hot plate size | 2700*1370*52mm |

| Closing time | 15s |

Plywood hot press

Plywood cutting saw machine

If you are interested in film laminating press machine and other plywood equipment, welcome contact us for more information