V. Components of the veneer Drying System

1.Main Structural Frame

This is the skeleton of the machine, typically welded from high-quality section steel (e.g., Q235B or higher grade) and weather-resistant steel plates. The entire structure is of a box-type design with internal support tracks for the multi-layer conveyor nets. To insulate, the side panels and roof are filled with high-temperature rock wool or polyurethane insulation material and clad with color steel plates to minimize heat loss.

2. Hot air circulating system

2.1 Heat Generator / Heat Source Unit:

Provides the heat required for drying. Options can be selected based on local energy availability: biomass burners, gas burners, oil burners, or steam heat exchangers, thermal oil heaters, etc. Modern systems often prioritize eco-friendly and economical biomass energy.

2.2 High-Temperature High-Pressure Centrifugal Fans: These are numerous and high-powered. Typically installed for each layer at the top and bottom of the drying chamber. Their role is to generate powerful, controllable airflow that forces hot air through the veneer layers for efficient heat exchange.

2.3 Air Ducts & Air Flow Plates:

Air ducts, made from galvanized steel sheets, channel the hot air from the heat source to various drying zones. Air flow plates (also called nozzle plates) are installed above and below each layer. They are equipped with nozzles of specific angles and diameters to ensure hot air is blown evenly and at high velocity across the veneer, preventing dry spots and airflow short-circuiting.

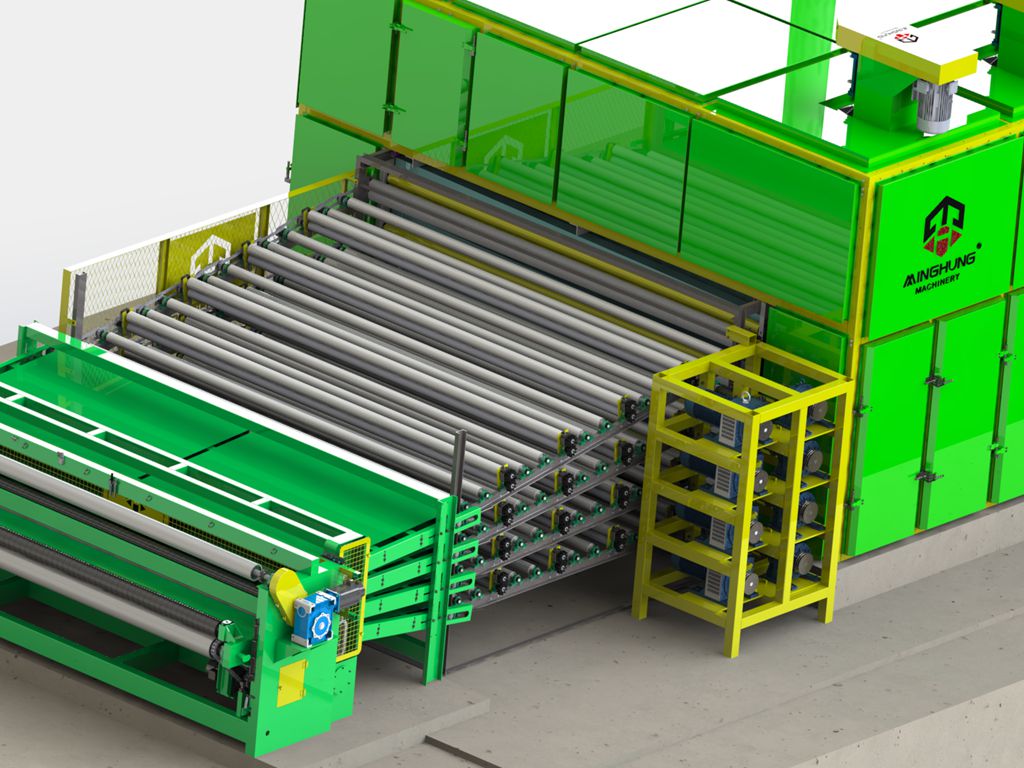

3. Material conveying system

3.1 Mesh Belts & Driving Unit:

High-strength stainless steel mesh belts or galvanized wire mesh belts are used to carry and convey the veneer sheets. They are driven by main drive motors via reducers and sprockets or drums. The speed is adjustable to control the drying time.

3.2 Feeding & Discharge Unit:

A feeding spreader ensures wet veneer is evenly laid onto the mesh belt without overlapping. The discharge end is usually equipped with an automatic stacker or conveyor to pile the dried veneer automatically, saving labor.

4. Moisture Exhaust System:

Comprises exhaust fans, ducts, and adjustable dampers. Its function is to continuously expel the high-temperature, high-humidity air evaporated from the veneer out of the drying chamber, maintaining an appropriate relative humidity inside to ensure drying rate and quality.

5. Intelligent Control System:

This is the "brain" of the dryer and a hallmark of modern equipment. The core typically consists of a PLC (Programmable Logic Controller) and a Color Touch Screen HMI (Human-Machine Interface). The system collects data from temperature and humidity sensors installed throughout the layers, automatically controlling the burner output, fan speed, exhaust damper opening, and mesh belt speed. Operators simply set the drying curve (e.g., temperature, humidity, time) on the screen, and the system runs automatically. It can often be connected to the internet for remote monitoring and diagnostics.

6. Fire Prevention System:

A critical safety component, includes spark detection and automatic extinguishing units installed in the feed inlet and ducts, which can instantly suppress sparks from the heat generator to prevent fires.

Detection Devices: Such as belt misalignment detection (to prevent the mesh belt from deviating) and over-temperature alarms, ensuring safe and continuous operation.

The multi-layer continuous veneer dryer is a highly integrated system of machinery, thermal dynamics, and intelligent electrical control. Its superior drying performance relies on the high-quality manufacturing of each component and the perfect matching and coordinated operation of the entire system.