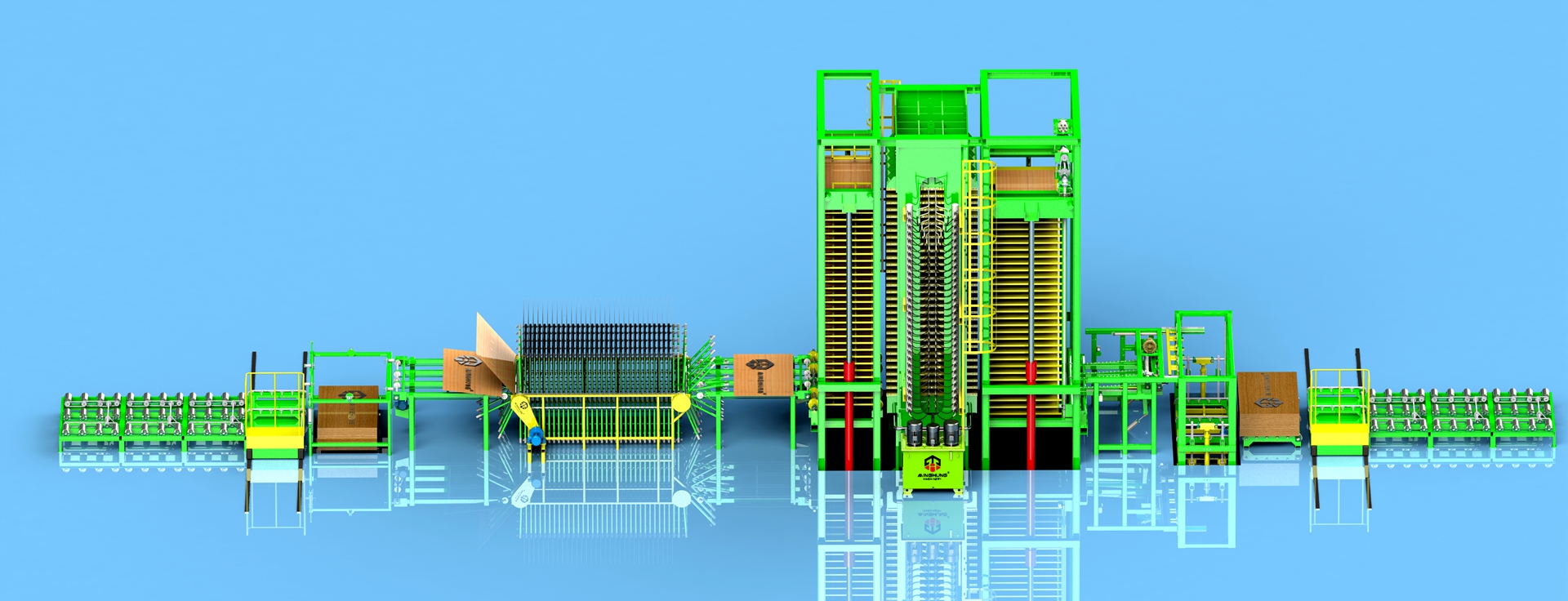

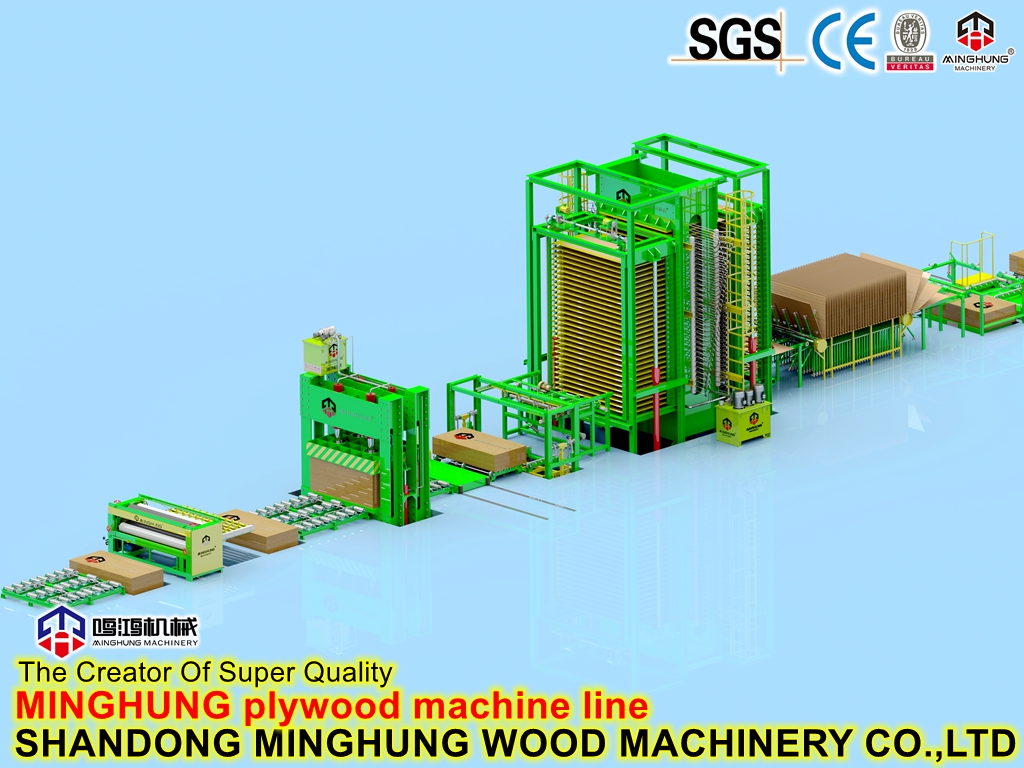

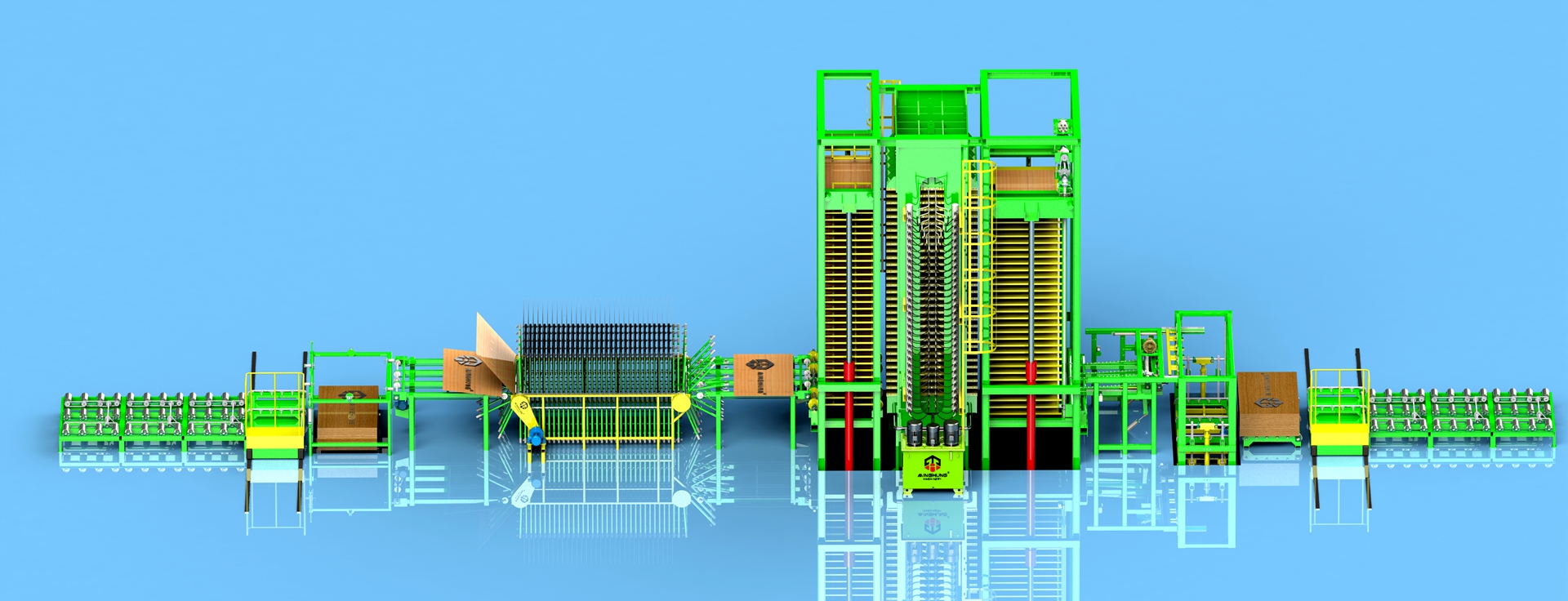

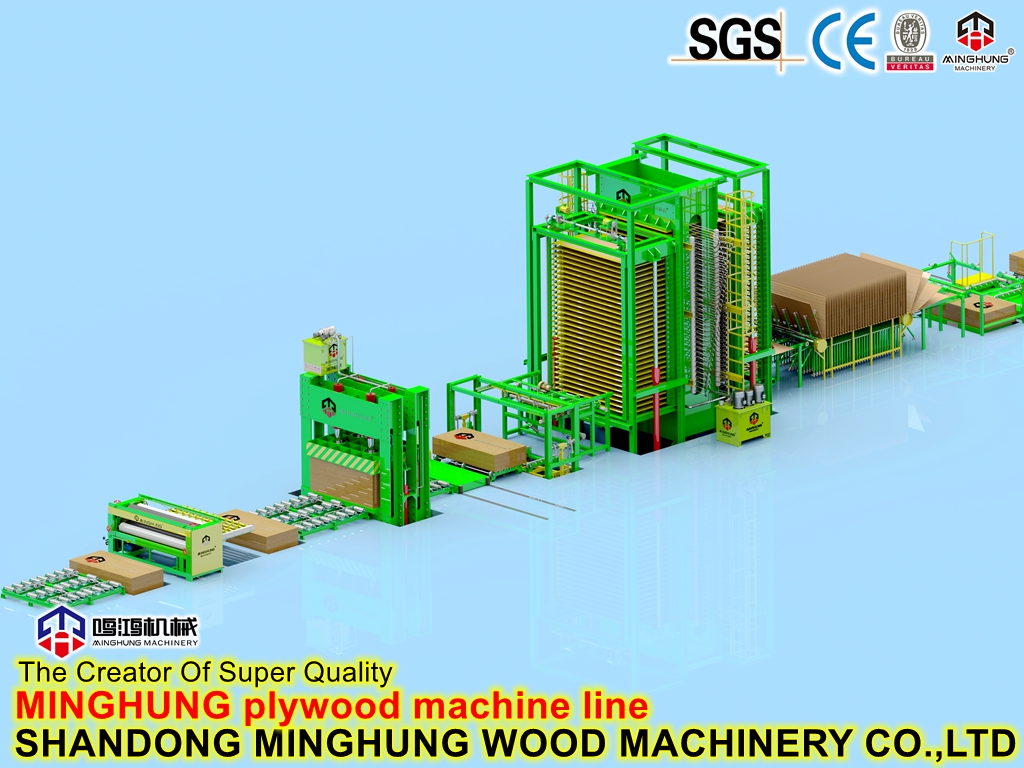

30 Layers Plywood Hot Press Machine with Automatic Loading And Unloading System

Streamlining Plywood Production with an Automatic Hot Press Production Line

Introduction:

In the realm of plywood manufacturing, efficiency and productivity are key factors that determine success. To meet the growing demand for high-quality plywood, companies are turning to advanced machinery that can streamline the production process. One such innovation is the Automatic Plywood Hot Press Production Line with Loader and Unloader and Stacker. This cutting-edge solution offers a range of hot press machines with varying layer capacities, including 10, 15, 20, 25, 30, 40, and 50 layers. In this article, we will explore the benefits and features of this state-of-the-art production line.

Enhanced Efficiency:

The Automatic Plywood Hot Press Production Line is designed to optimize efficiency and reduce manual labor. With the inclusion of a loader, unloader, and stacker, the line minimizes the need for human intervention, allowing for a continuous and uninterrupted production process. This automation not only saves time but also reduces the risk of errors, ensuring consistent and precise results.

Versatility in Layer Capacities:

To cater to different production requirements, the line offers a range of hot press machines with varying layer capacities. Whether you need a 10-layer machine for smaller production volumes or a 50-layer machine for larger-scale operations, this production line has you covered. The flexibility in layer capacities allows plywood manufacturers to adapt to market demands and optimize their production output accordingly.

High-Quality Plywood:

The Automatic Plywood Hot Press Production Line guarantees the production of high-quality plywood. The hot press machines ensure uniform heat distribution and pressure, resulting in plywood with excellent bonding strength and dimensional stability. This ensures that the final product meets the highest industry standards and satisfies customer expectations.

Safety and Reliability:

Safety is of utmost importance in any manufacturing setting. The Automatic Plywood Hot Press Production Line incorporates advanced safety features to protect operators and minimize accidents. Additionally, the line is built with robust materials and components, ensuring long-term reliability and durability. This reduces downtime and maintenance costs, allowing manufacturers to focus on their core operations.

Conclusion:

The Automatic Plywood Hot Press Production Line with Loader and Unloader and Stacker revolutionizes the plywood manufacturing process. By automating various stages and offering a range of hot press machines with different layer capacities, this production line enhances efficiency, guarantees high-quality plywood, and prioritizes safety. With this advanced solution, plywood manufacturers can meet market demands, optimize production output, and stay ahead of the competition.

| Automatic 30 layers hot pressing line introduction |

This is Multi-layers 30layers automatic hot pressing line with loading and unloading system. So the whole hot pressing line is automatic and no need workers. Hot press machine function for pressing glued plywood and make plywood be solid and strong, so it can be used in different application like constructure, furniture, packing, marin and others.

30Layers hot press machine can press 30pcs plywood at the same time. The whole working way is: the Automatic such system convey plywood to each layers of auto feeder, auto feeder automatic life and down to accept plywood, until each layers full of plywood, it will automatic convey plywood into hot press machine, Press hot press start button, it will automatic close and press plywood. After hot press machine opened, the auto system will convey pressed plywood out and stacking them.

When the hot press machine layers more, it is better use the auto loading and unloading, because it will be more efficiency and keep worker safety.

| 30Layers hot press machine at our clients factory |

Until now, we have exported many sets hot press machine to different countries, and got good feedback. Hot press machine can be different daylights and pressure according to different requires.

| Hot press machine mainly parts |

Oil cylinder

Hydraulic station

System to adjust plywood

One set hot press machine mainly consist by press machine frame, hydraulic station, oil cylinder, hot plates, electric system, and auto system

For our automatic hot pressing line, in here we can promise you that all parts and materials are good and high level, keep machine strong and stable, and long life span, you no need spend much time to maintain it

| Plywood hot press loading pictures |

Before loading your hot press machine and plywood machine, we will disassembly well and packing the parts, and during loading, we will take picturs for you

| China MINGHUNG Plywood machine |

We as China big and professional plywood machine manufacturer, we can offer you all necessary machine for making plywood board and veneer sheets, and offer the suitable and strong machine according to your own conditions. Until now we have been more than 20 years in this business, and continuous to improve our machine every year, so now we have got many good clients.

Veneer machine includes debarker, peeling lathe, log loader, stacker, Veneer dryer includes roller dryer, wire dryer and press dryer; Glue machine, Plywood lay-up line, Core composer, Plywood cold press machine, Hot press machine, Plywood edge sizing machine, Plywood sander and calibrator, Veneer knots fixing machine, Plywood putty line, Plywood turnover machine, Lift table and others

| Related Plywood machine |

Glue spreading machine

Cold press machine

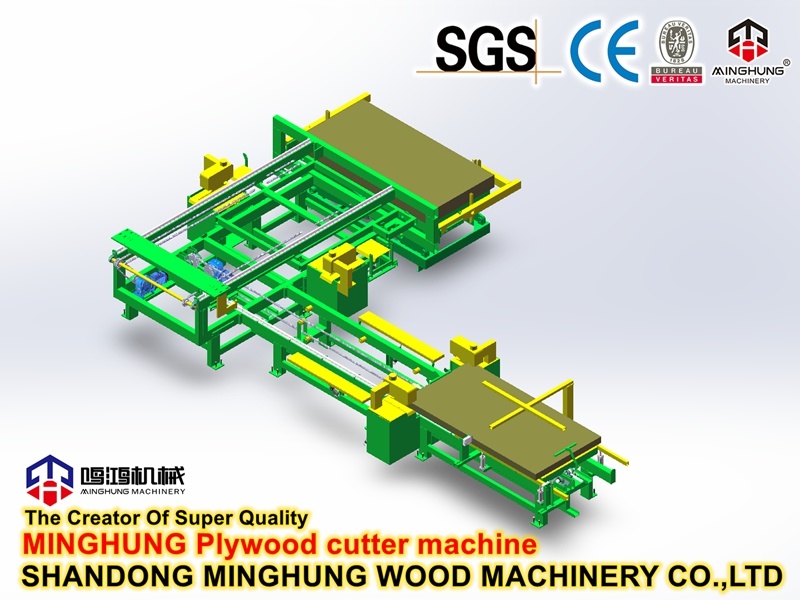

Plywood roller edge trimming sawing line

Welcome contact us for more information