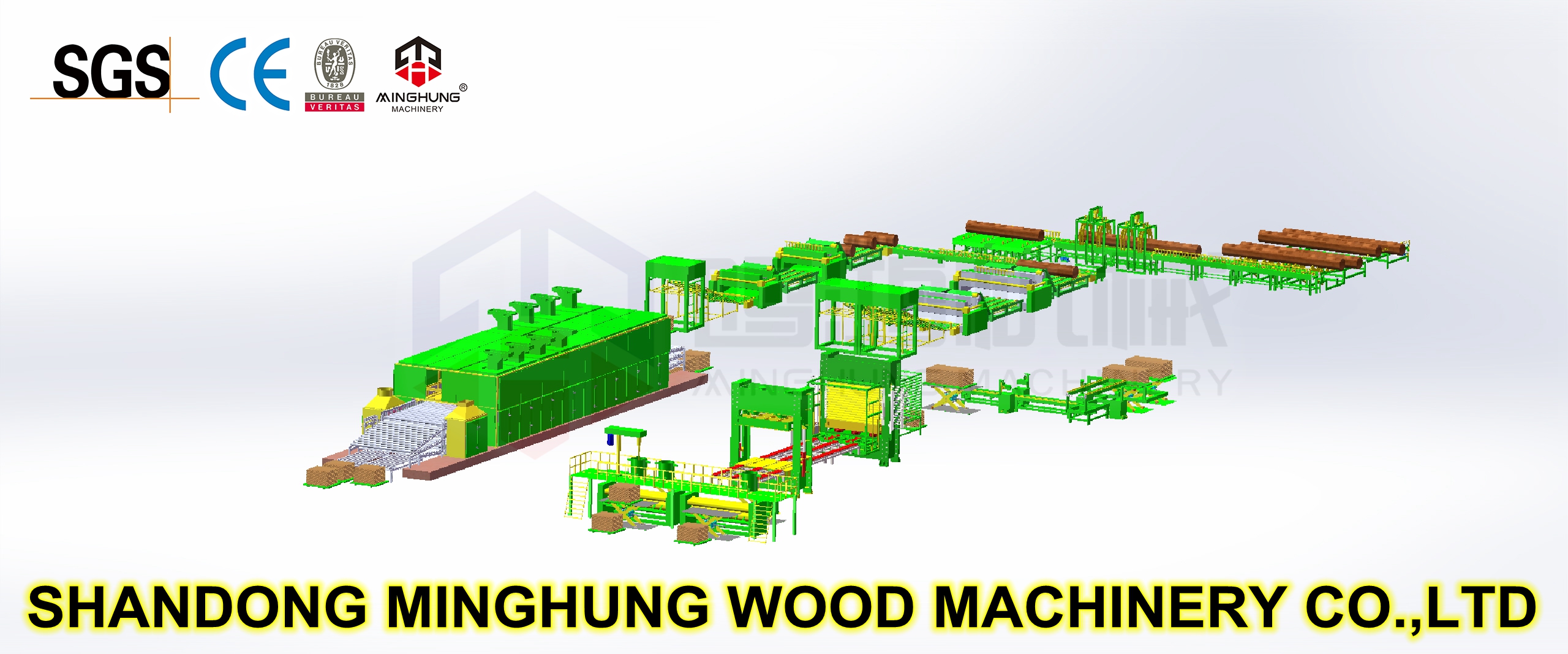

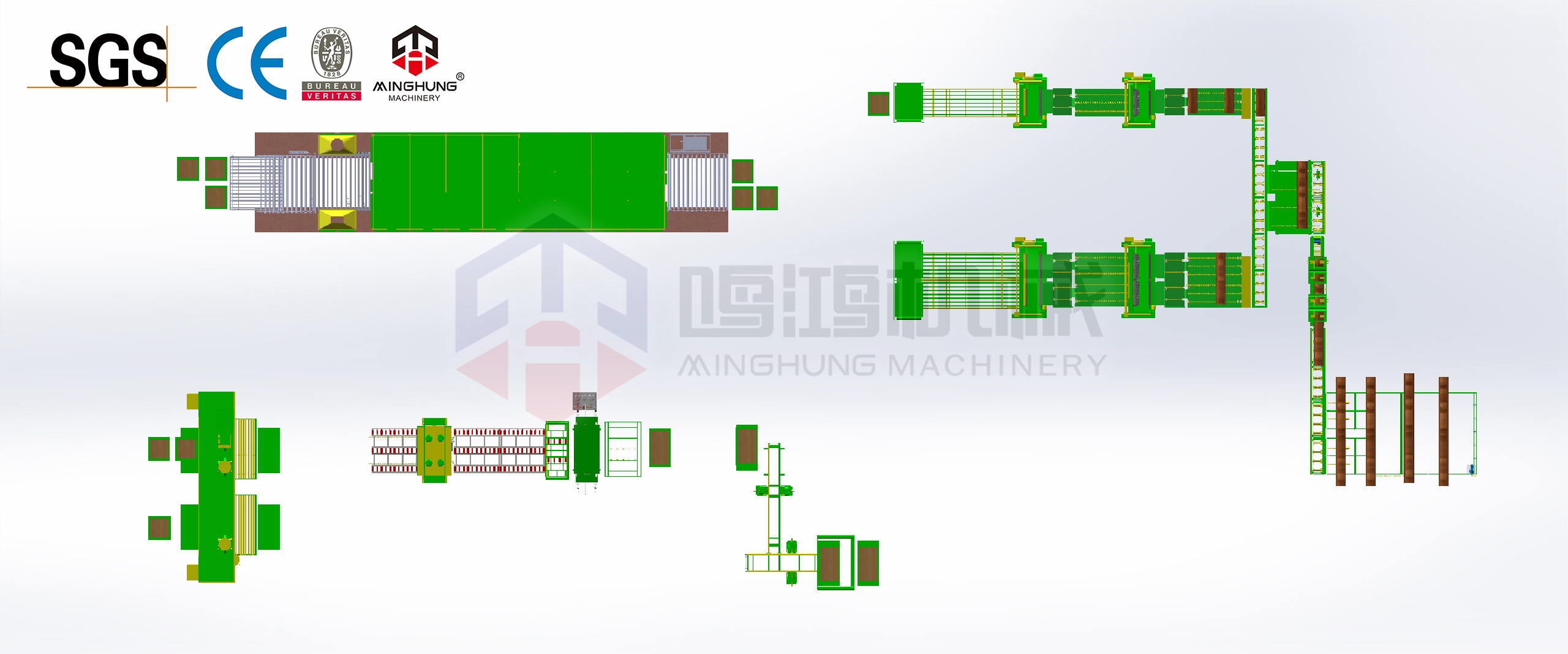

We are manufacturer of veneer machine and plywood machine since 1998, having mature and advanced technology and abundant experience. We have independent research&develop team, professional sales team, and well-trained after-sales team, until now, our machine have been exported more than 20 countries, and obtains customer’s recognition and praise.

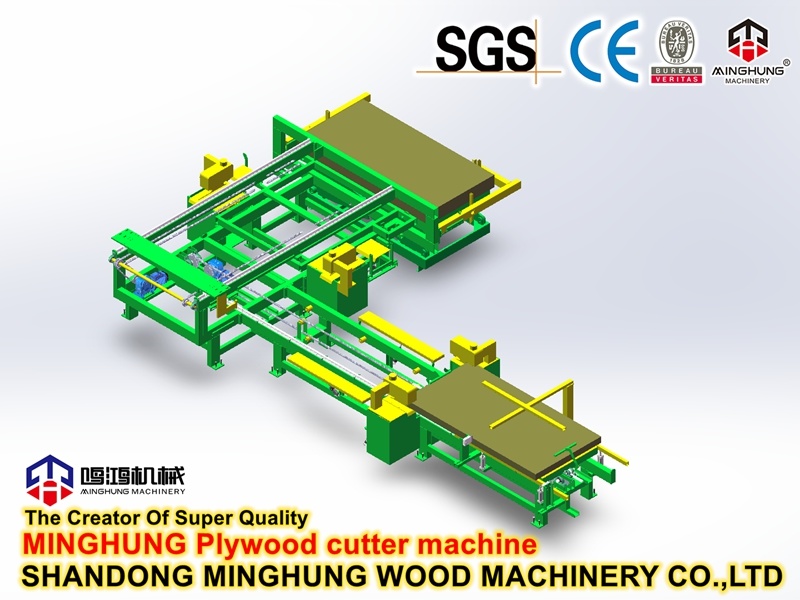

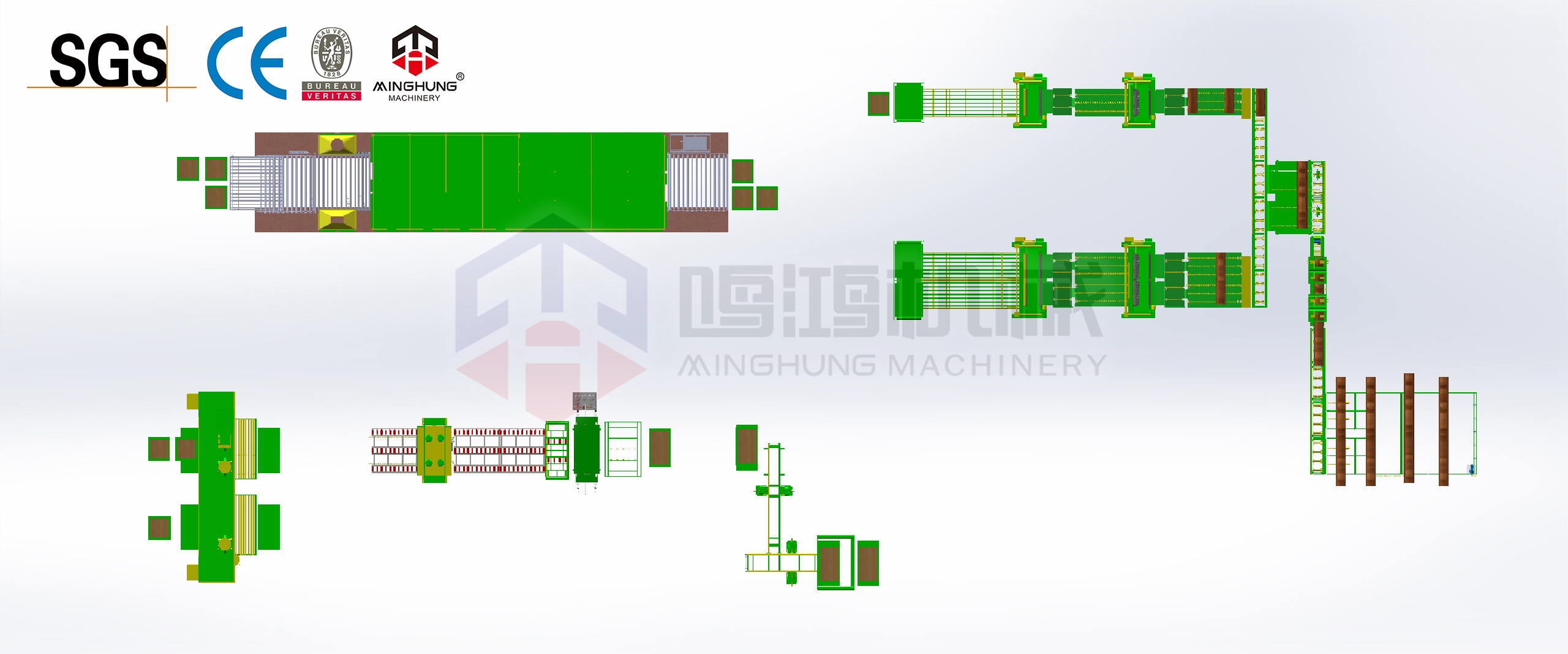

Our product mainly include: wood debarker, veneer peeling machine, veneer dryer, glue mixer, glue spreader machine, core composer, veneer joint machine, plywood veneer paving line, hydraulic cold press machine, hydraulic hot press machine, plywood edge cutting saw, sanding machine, lift table, plywood turnover.

Our machines suitable for manufacturer which produce thin wood veneer, kinds of plywood, film faced plywood, furniture plywood, construction plywood, lvl, etc.

Machine has different types, we usually produce machine according to your own conditions, and if you have special requires and ideas, we also can customize.

For example:

1. whatsapp: +8618769900191

2. WeChat: +8619953900191

3. web: www.plywoodmachineline.com

4. email: shandongminghung@gmail.com

5. Veneer peeling machines have 4 feet (max length 1500mm) and 8 feet (max length 2700mm); speed is divided into general speed and fast speed; The machine configuration is different according to your wood material, if your wood is hard wood, we will offer a higher configuration to produce good quality thin wood veneers.

6. The advantages of our wood veneer peeler are:

7. (1) veneer thickness is very accurate and balanced, and the two sides of veneer are very smooth.

8. (2) machine body uses very thick steel and high quality, very heavy machine, make sure the machine is very stable when working.

9. (3) all the main parts go through accurate processing, make sure the machine is in good condition and good quality.

10. (4) veneer machine uses a fully enclosed feed screw, protects damage from the outside, keeps the machine long life, this is our factory's patent, you can use many years.

11. (5) Veneer slicing machine is easy to operate, through the CNC screen, you can adjust the width and thickness of the veneer as you wish.

12. (6) Veneer machines have automatic oil devices, can maintain engine parts and save labor.

Veneer dryer, which has veneer press dryer and roller dryer, and veneer press dryer divides into square tube veneer press dryer and hot platen veneer press dryer. If you don’t require big production capacity per day, choose veneer press dryer is good and enough; if you require big capacity, then choose roller dryer is better.

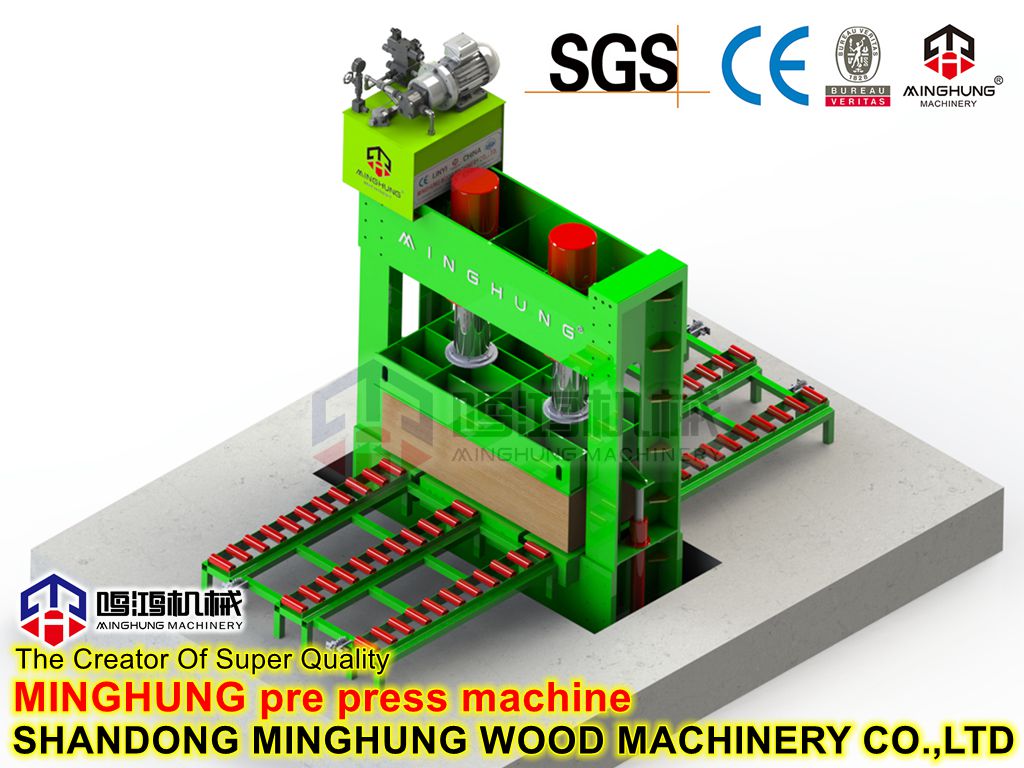

13. Cold press has up-cold press and download cold press, pressure can be 400t, 500t, 600t, 800t, etc.

14. Hydraulic hot press machine has different layers, can be 8 layers, 10 layers, 12 layers, 15 layers, 20 layers, 25 layers, etc. Pressure can be 400t, 500t, 600t, 800t, 1000t, 1200t, 1600t, etc.

And if you laminating face veneer, or melamine, we also have suitable hot press machine.

15. Glue spreader has 4feet and 8feet, and has common standard and high standard, you can choose according to your real conditions and needs.

16. Core composer/veneer joint machine and plywood veneer paving line/assemble line are not the necessary machine for producing plywood, but if you plan to enlarge your production capacity, these two machines will help you save labors and improve high efficiency, and at the same time, your plywood will become more good quality.

17. Sanding machine has light type and heavy type, has one head, two heads, and three heads, through calibrating and polishing, your plywood will become very beautiful.

Each production step through special workers manufacture, machine will be tested many times before delivery until ensure it is in a good conditions.

We welcome you come to visit our factory and check machine, the moment that you choose us and order from us, we have been your sincere and good partner, we can offer plant planning, machine foundation drawing, machine installation, teach your workers how to operate and maintain, and your workers can come to our factory study.

we insist offer the most suitable machine to you, not the most expensive one, our purpose is service more clients, let them get one good and favorable machine, and help their business develop better and better.

I am here wait for you.

CONTACTS:

MARK ZHAI

Whatsapp: +86 18769900191

email: minghungmachinery@gmail.com