Minghung Wire Veneer Drying

Veneer dryer

The veneer (plywood) dryer can be divided into three heating forms: hot air heating, steam heating, and heat transfer oil heating according to different heating forms. According to different fuels, it can be divided into fuel oil, gas, coal, firewood, and electricity. The equipment can be divided into manual loading and automatic loading. The veneer enters the dryer, and according to the set value, the temperature and humidity in the dryer are automatically controlled, so that the drying material can be leveled and the moisture can be controlled uniformly. The equipment can determine the size of the equipment according to the user's output, and it can be divided into automatic board and manual board. This equipment has large output, high degree of automation, low cost of use, uniform drying, and good effect. Through drying, it can avoid mildew and blue change of plates in high temperature and high humidity environment (such as eucalyptus wood, rubber wood, poplar, camphor It is ideal in the field of veneer processing, flame retardant veneer production, plywood production, flame retardant plywood production, and dyed veneer (board) production. Veneer drying equipment.

product description

Product advantages: This equipment has a high degree of automation, low operating cost, small footprint, and can be operated 24 hours a day, saving labor, and the annual labor cost saving can reach 150,000 US dollars.

Obvious features:

1. High degree of automation, automatic loading, labor saving, automatic heating, dehumidification, high drying intensity, long drying time, high moisture saturation, and energy saving.

2. Dry evenly. The peeled veneer undergoes heat exchange and moisture removal in multiple sections, and after drying for about 1.5 hours, the moisture content is low and uniform, which can meet the production needs of veneer and plywood.

3. The output is large. According to the needs of different users and different materials, the output of the equipment can reach 1---5 cubic meters/H.

4. The equipment adopts fin-type heating device, which has large heat exchange area, fast temperature increase, large circulating air volume, many cycles, high heat exchange efficiency, high exhaust water saturation, energy saving, and low use cost, which is better than roller type veneer. The drying equipment saves energy by more than 40% (the roller adopts the air spray method, the contact time between the hot air and the plate is short, and the heat exchange efficiency is low).

5. A piece of equipment investment can be used for more than ten years, super cost-effective

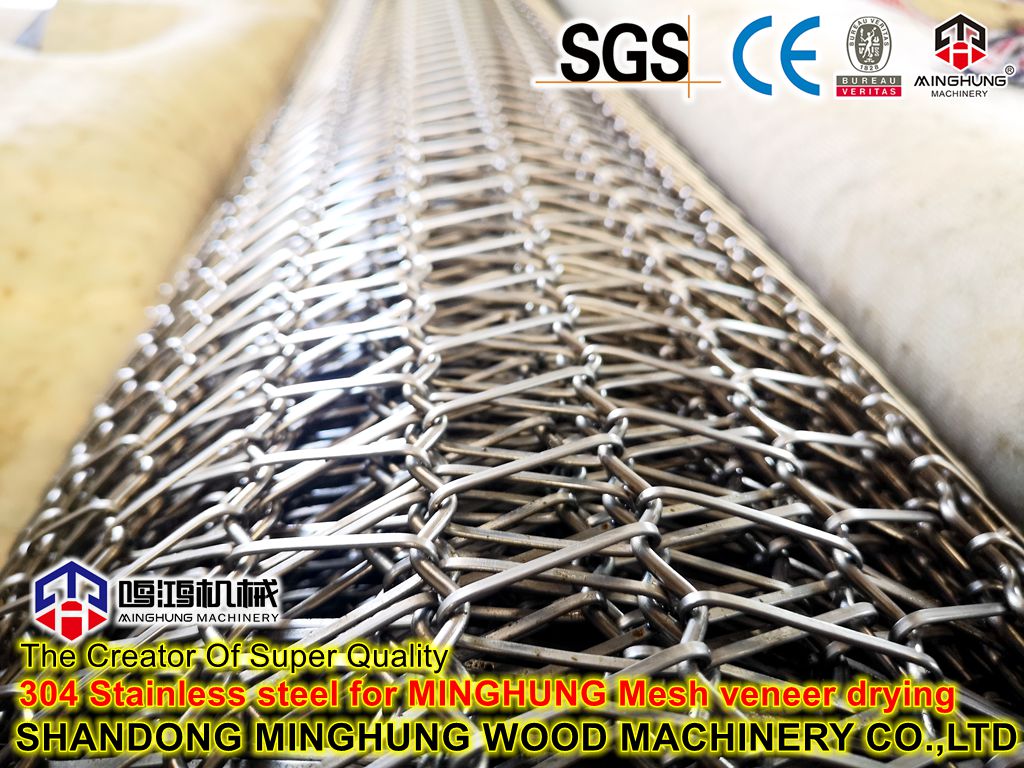

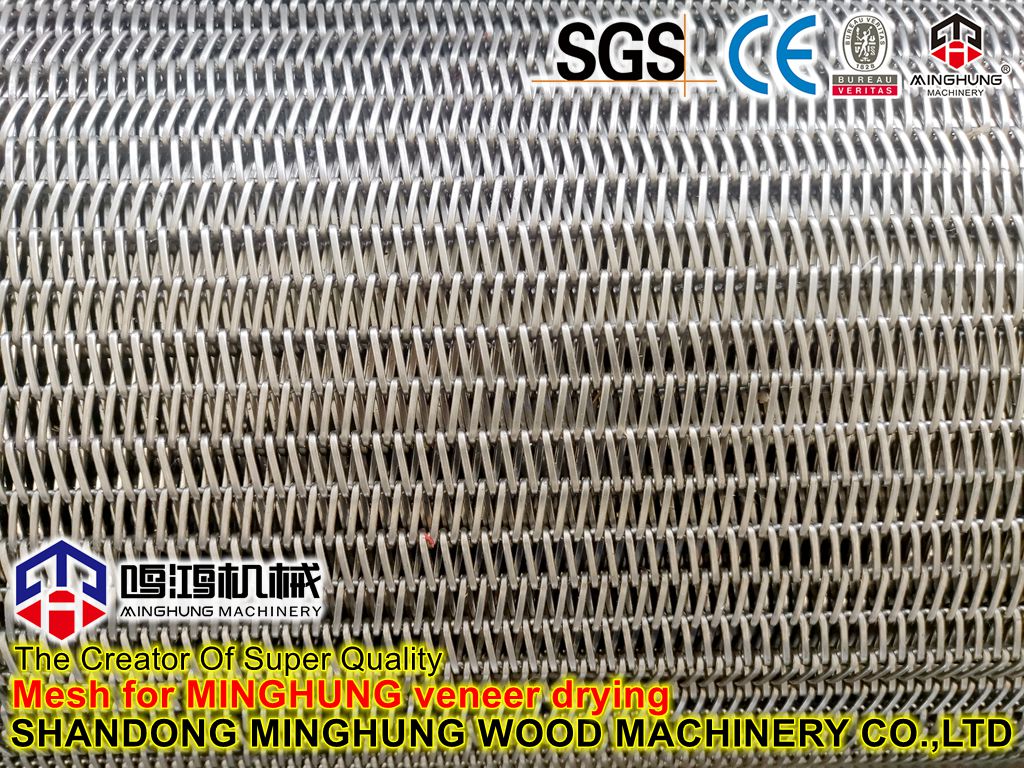

6. The failure rate is low, the network belt is worn, and the network is disconnected, and the failure rate of the pallet is low.

7. The equipment adopts vertical plate loading and drying. The operation time of the plate skin in the equipment is long, which can reach 1-2 hours. The temperature can be controlled according to the section. 13----15min, the folding type veneer dryer has large output, low energy consumption and low drying cost.

We have professionally designed according to different types of dryers, positive pressure fans and negative pressure fans, different fans for different veneer drying equipment, energy-saving, high-efficiency design concepts provide an effective guarantee for improving the quality of veneer drying products .

We have professionally designed according to different types of dryers, positive pressure fans and negative pressure fans, different fans for different veneer drying equipment, energy-saving, high-efficiency design concepts provide an effective guarantee for improving the quality of veneer drying products .

HEAT CONDUCTION HEAT SINK:

HEAT CONDUCTION HEAT SINK:

Heat conduction heat sink, used for MINGHUNG veneer drying, the warp is made of aluminum, the characteristics of aluminum material is good heat conduction effect, low heat loss, can better improve heat conduction efficiency, internal design forced circulation, heat conduction effect is better than traditional heat dissipation Warp increased by %70. Greatly improved energy utilization.

Heat conduction heat sink, used for MINGHUNG veneer drying, the warp is made of aluminum, the characteristics of aluminum material is good heat conduction effect, low heat loss, can better improve heat conduction efficiency, internal design forced circulation, heat conduction effect is better than traditional heat dissipation Warp increased by %70. Greatly improved energy utilization.