II. Core Equipment for 24/7 Continuous Production Lines

1. Raw Material Processing Section

- Moisture-Resistant Additive System:

- Paraffin melting tanks (constant 80~90°C) + high-pressure atomizing nozzles for uniform coating on particles.

- Corrosion-resistant high-precision metering pumps (±0.5% accuracy) for PMDI resin.

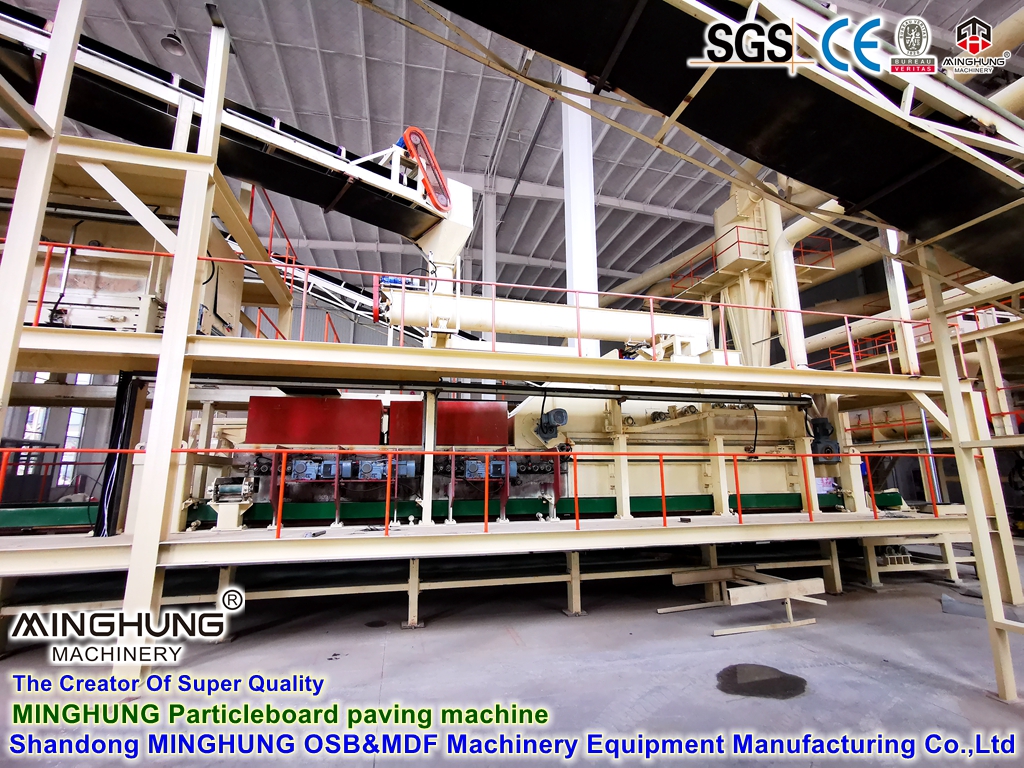

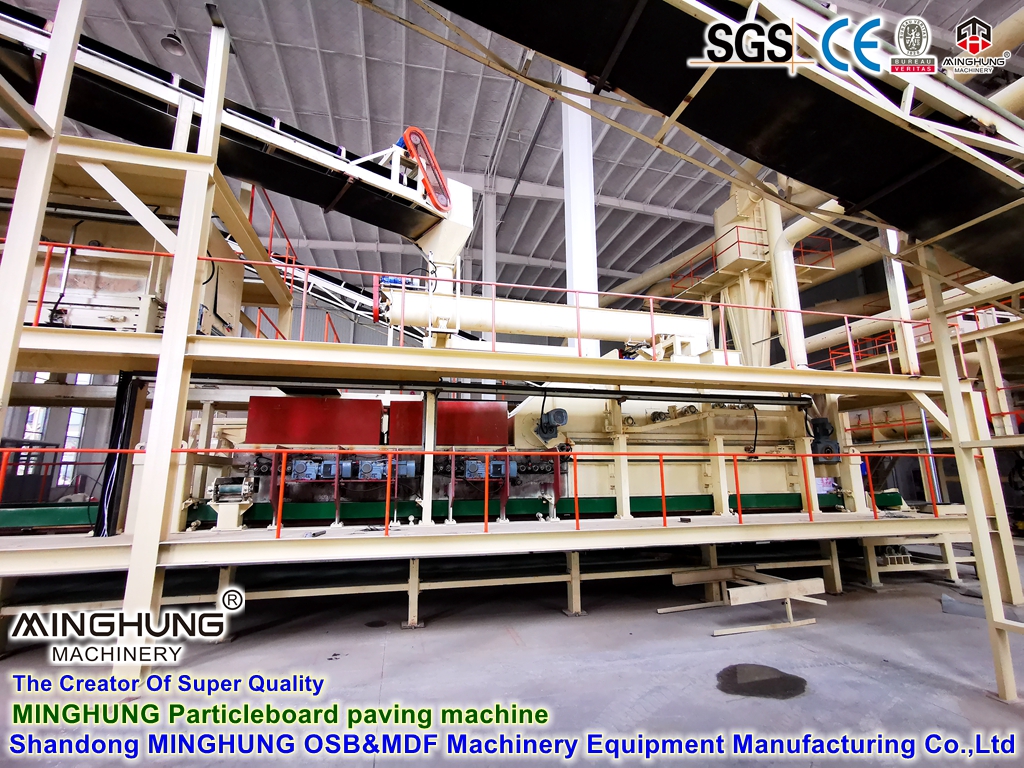

2. Forming and Pre-Pressing System

2.1 Moisture-Resistant Forming Station:

Three-layer forming (fine surface layers / coarse core layer) with online NIR moisture detectors for dynamic resin adjustment.

Airflow formers: Ensure uniform distribution of fine particles to reduce surface porosity.

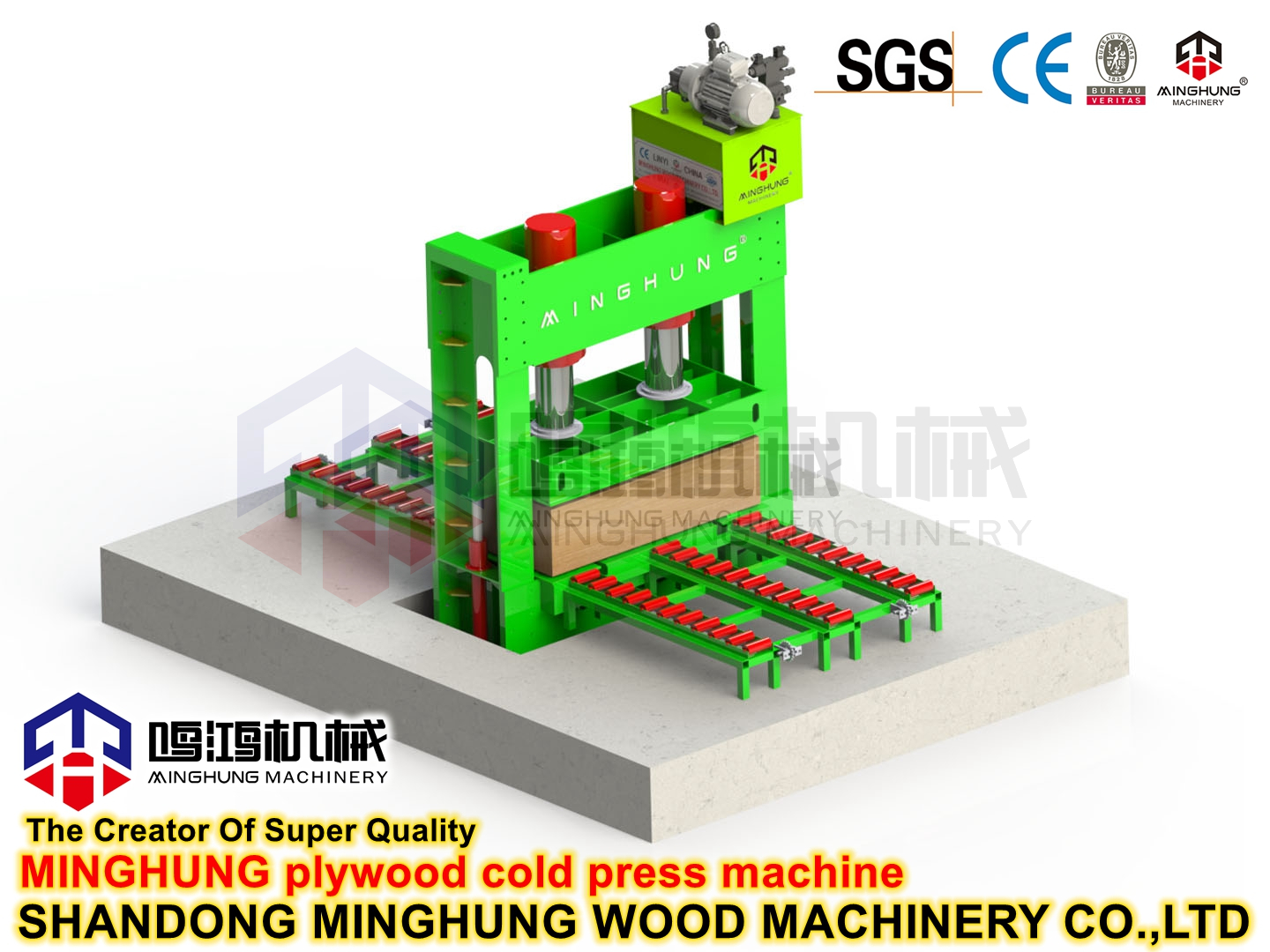

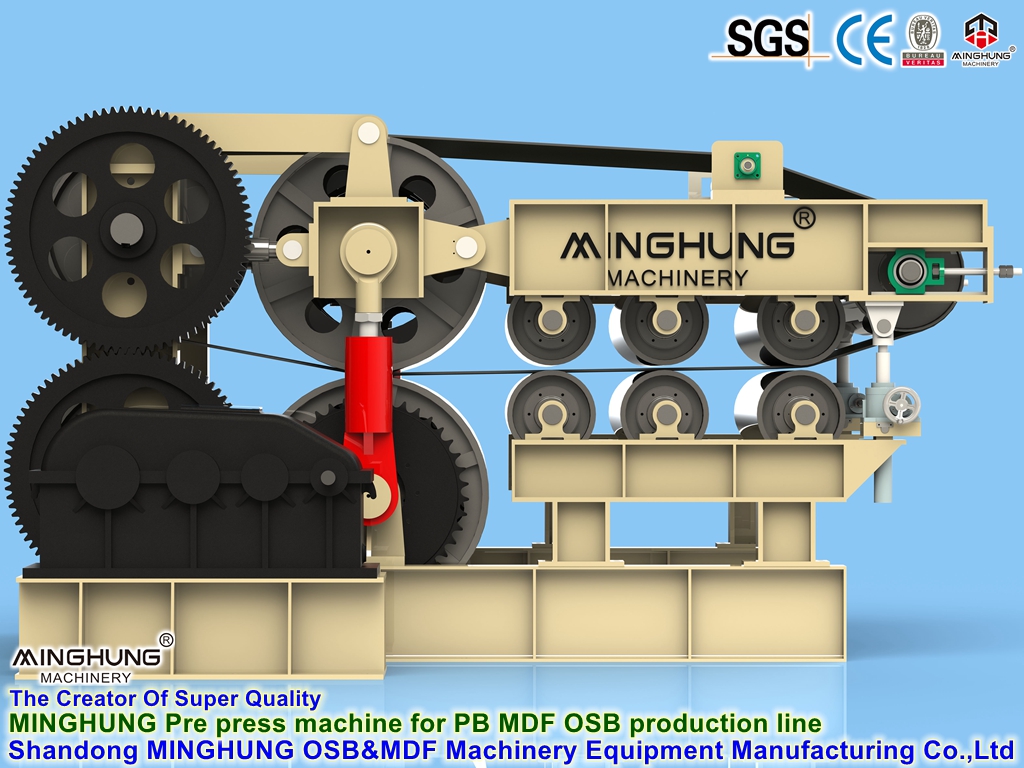

2.2 Continuous Belt Pre-Press:

Pressure up to 5 MPa, compression ratio ≥2:1 to eliminate internal air pockets.

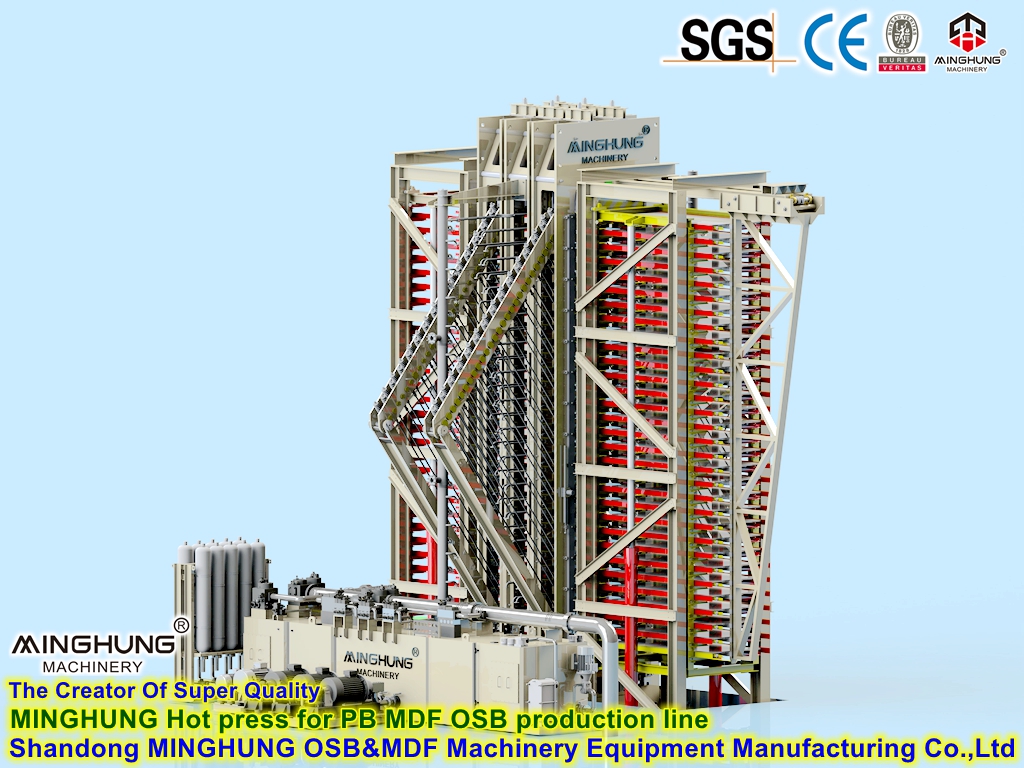

3. Continuous Hot Press (Core Equipment)

Parameter | Moisture-Resistant Board Design | Standard Particleboard |

Heating Method | Dual-medium (thermal oil + steam) | Single thermal oil |

Pressure Range | Max. 50 MPa | Typically ≤40 MPa |

Temperature Control | Multi-zone control (≥8 zones) | 4-6 zones |

Effective Length | ≥60m (80m+ for thick boards) | 40-50m |

Steel Belt Cooling | Integrated roller water-cooling | None/simplified cooling |

4. Post-Processing System

4.1 Online Quality Monitoring:

- X-ray density scanners: Real-time density profiling with automated press parameter feedback.

- Microwave moisture detectors (±0.2% accuracy) linked to drying kilns.

4.2 Enhanced Cooling Section:

- Multi-stage roller cooling (water spray + air cooling) ensures board temperature ≤45°C before cutting to prevent warping.

III. Key Technologies for 24/7 Operation

1. Reliability Engineering

Redundant Hydraulics: Dual pump stations + accumulators with oil temperature control (±2°C).

Steel Belt Steering: Laser-guided sensors + servo motor closed-loop control (deviation <1mm).

Rapid Press Plate Replacement: Modular design (<10 minutes per segment).

2. Intelligent Process Control

- Process Database:

Stores optimized pressure-temperature-speed profiles for different board thicknesses/densities.

- AI Failure Prediction:

Vibration sensors monitor main bearings, enabling 2-week advance maintenance alerts.

3. Zero-Downtime Maintenance

- Online Cleaning:

Automatic steel belt scrapers + pulse-jet dust removal reduce downtime by 30 mins/shift.

- Preventive Maintenance:

Replace wear parts (seals, thermocouples) during production gaps (<15 mins/action).

IV. Energy and Efficiency Optimization

1. Heat Recovery

- Press exhaust heat reclaims via heat exchangers to preheat mats (≥15% energy savings).

- Cooling water reused for resin tank temperature control.

2. Speed-Thickness Synchronization

Thickness (mm) | Max. Line Speed (m/min) | Standard Particleboard |

8-12 | 1,200-1,500 | Single thermal oil |

15-18 | 800-1,000 | Typically ≤40 MPa |

25-30 | 400-600 | 4-6 zones |