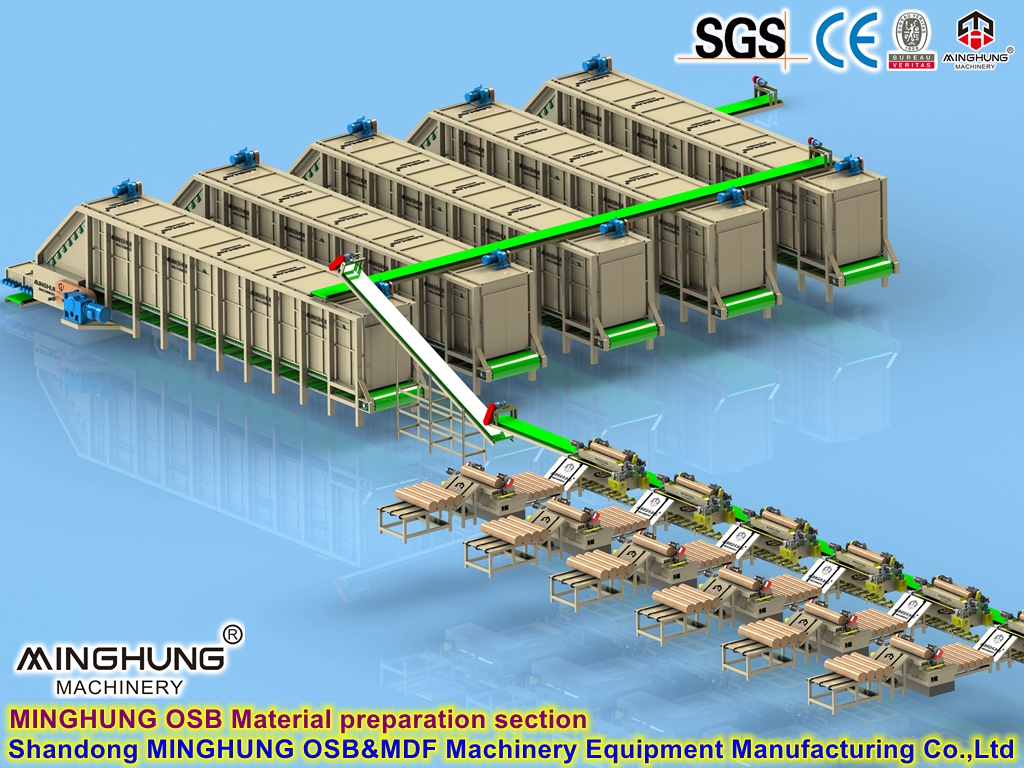

China Professional Plywood Veneer Machine-MINGHUNG MACHINE introduction: Shandong MINGHUNG Wood Machinery Co.,Ltd is one famous manufacturer of plywood machine in China, located in Linyi city.

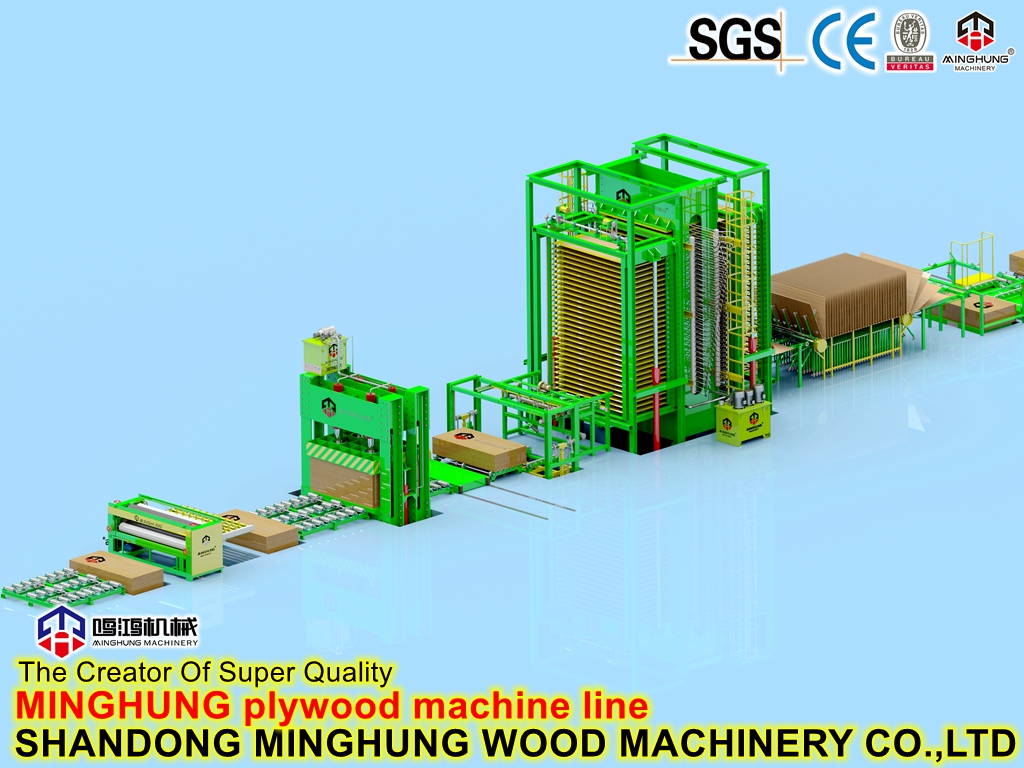

Our company integrates design, research and development, production and sales, and works closely with China's advanced scientific research institutions. We have a strong research and development team, at present, our machinery has won a number of national patents.

Pay more attention to machine details, details determine sucess or failure, so we continuous improve and optimize machines' performance, strictly control each production step, using advanced lathe processing machine, and through many times inspections, make sure our machine accurate and durable.

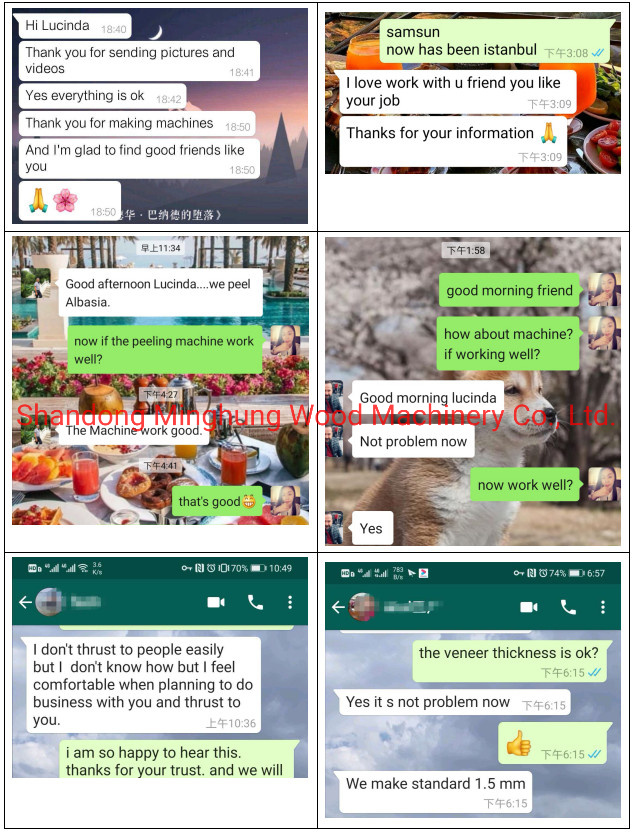

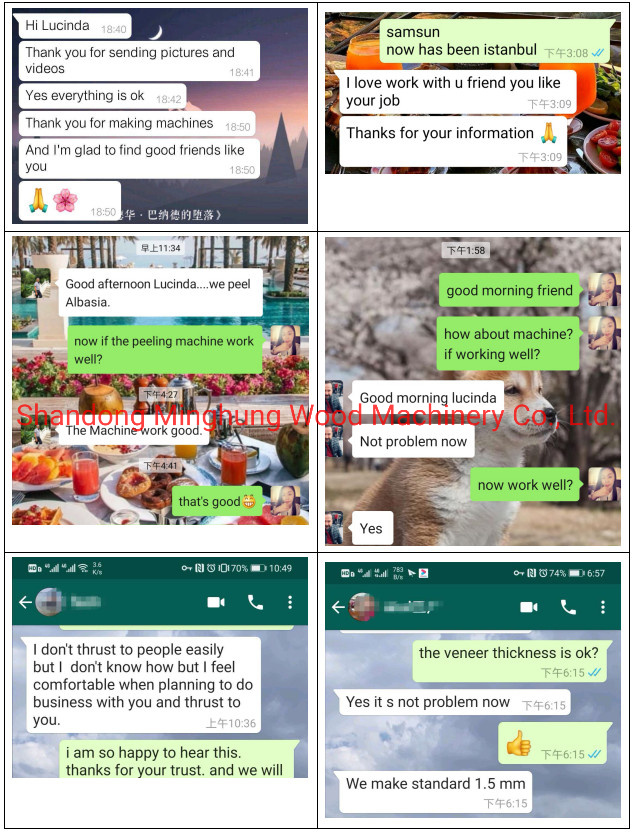

Scientific and technological innovation oriented, quality-based, service supremacy, we offer full complete range of plywood production solution and technology support for our customers. Yet our machines have been exported more than 30 countries and regions like Russia, Poland, Ukraine, Portugal, Bulgaria, Romania, Turkey, Egypt, Morocco, Indonesia, etc, and get good feedback.

Veneer peeling machine's function is processing wood into veneer, its standard size is 4feet and 8feet, also we can customize, the related machine is wood debarker, veneer stacker.For keeping veneer quality good, we focus on each production step, heavy duty make machine very stable, the precise feed screw make sure veneer thickness accurate, the roller is chromed, long lifespan, big power can offer powerful energy to driving machine process hardwood.

Hydraulic plywood hot press machine is one important machine for making plywood, it can be different pressure and layers, With reasonably designed hydraulic system, anti-rust and alloy casting cylinder, smooth and hard hot platen, machine heavy duty, make sure pressing plywood balance and high efficiency.

With high efficiency sales team offer 24 hours online service, the professional technical team and after-sales service team offer plant layout, machine drawings, and after-sales service.

Choose us, you need not worry any Our clients:

When we start cooperate, we will offer you life span service, always be there help you solve problem and give professional suggestions.

when machine after custom clearance, soon reach your factory, our engineer will prepare go to install your machine, and teach your worker how to operate and maintain.

Before we produce your machine, our engineer will be together have a meeting discuss how to design your machine, which place we can upgrade again, which place we can make it stronger again. so we can promise the machine offered to you, must very good quality and good working conditions. Delivery:

>>> Before delivery, we will test veneer machine and send you test video.

>>>When loading, we will share loading pictures with you.

>>> After ship leave, we will offer container and ship information to you. Clients Comment:  Some Question you may want to know: 1> Warranty 2 years for main parts.

Some Question you may want to know: 1> Warranty 2 years for main parts.

2> Production time 1 month

3> Installation

our engineer can go to install machine.

4> Documents

All you need for do custom clearance, we all offer.

5> Payment terms

T/T. L/C

6> Customize machine

except the standard size 4feet and 8feet, yes, we can customize veneer machine.

Contacts:

Mark: +8618769900191

Ali: +8615805496117

Lucinda: +8615805493072

Email: minghungmachinery@gmail.com

Welcome contact us for more information about plywood machinery and veneer lathe.