This process is designed for continuity, high efficiency, and minimized interruption, like a highly coordinated industrial symphony.

1. Automatic Feeding & Crushing/De-ironing: Forklifts feed mixed waste wood (e.g., nailed formwork, pallets) into a heavy-duty crusher. The machine crushes the material and thoroughly separates ferrous metals (nails, screws) via powerful magnetic systems.

2. Screening/Cleaning & Drying: The crushed chips pass through a drum screen to remove sand, stones, and concrete residues, and may be cleaned (air washing or water washing) to achieve clean chips. The chips are then evenly dried to the optimal moisture content (8-12%) in an efficient rotary dryer.

3. Precise Glue Blending & Uniform Forming: The dried chips are mixed with a precisely measured adhesive (e.g., MDI, UF resin) in a large blender, ensuring each chip is uniformly coated. A mechanical or air forming machine then creates a mat with extremely consistent thickness.

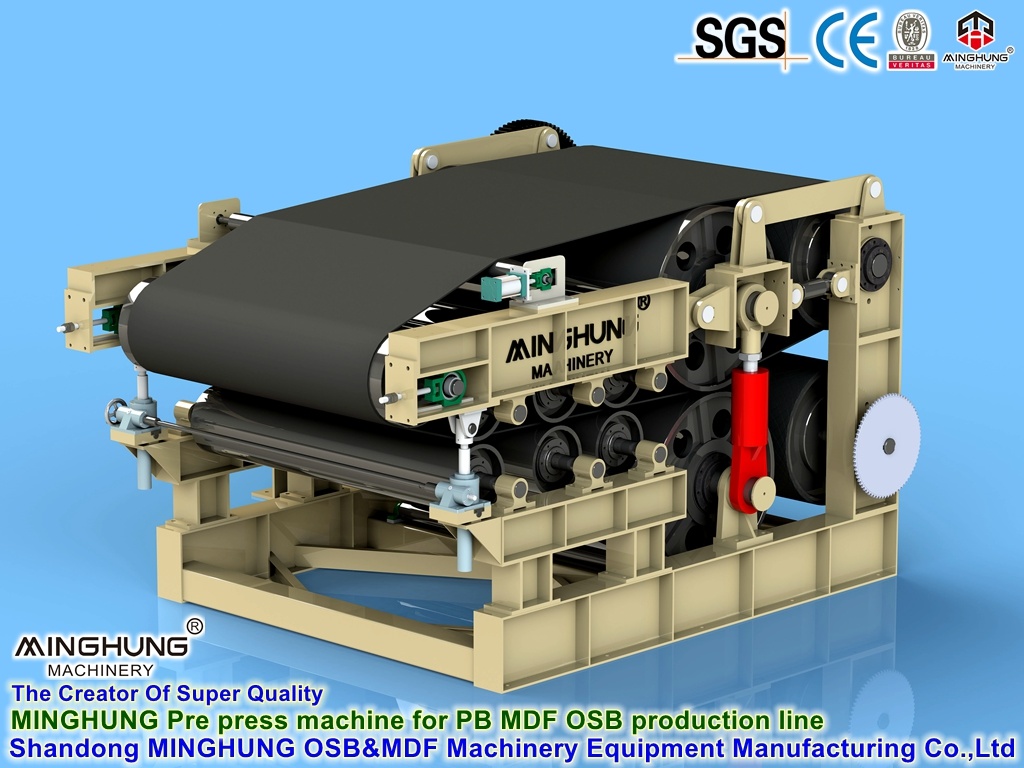

4. Pre-pressing & Continuous Hot Pressing: The fluffy mat is initially compacted by a cold pre-press and then automatically conveyed into a continuous press (or high-efficiency multi-opening press). Under high temperature and pressure, the mat is instantly pressed and cured.

5. Online Cutting & Cooling/Stacking: The continuous board exiting the press is immediately cut to standard sizes by an online cross-cutting and trimming system. The boards then enter a long roller cooler for gradual cooling to release internal stress and prevent warping. Finally, robots or automatic stackers stack and package the finished products.

Core Feature: Buffering silos and intelligent control systems seamlessly connect each step of the process, ensuring the hot press can continue working even if upstream feeding has brief pauses, enabling true 24/7 uninterrupted production.

Equipment | Core Function & Features | 24/7 Continuous Operation Upgrade Design |

Heavy-Duty Formwork Crusher | The core for crushing nail-embedded wood. | Dual-motor drive design, hydraulic opening for quick hammer change, multi-stage de-ironing (suspended + drum magnets) ensures >99% metal removal rate. |

Efficient Triple-Pass Dryer | Dries chips to standard moisture content. | Gas heating for precise temperature control; superior insulation design for high thermal efficiency; explosion-proof and fire-proof design for safety. |

Continuous Press | The heart of the production line. Applies continuous heat and pressure to form and cure the mat. | Servo-hydraulic system for stable and precise pressure; thermal oil heating for uniform platen temperature; modular design for quick replacement of key components. |

Central Control System | The brain of the production line. | Industrial PC + High-end PLC for fully automated integrated control; integrates remote monitoring and early warning functions, accessible globally via the internet. |

Predictive Maintenance System | The guardian of continuous operation. | Integrates vibration sensors, temperature sensors, and automatic lubrication systems to provide early warnings of potential equipment failures, shifting from "reactive repair" to "predictive maintenance". |

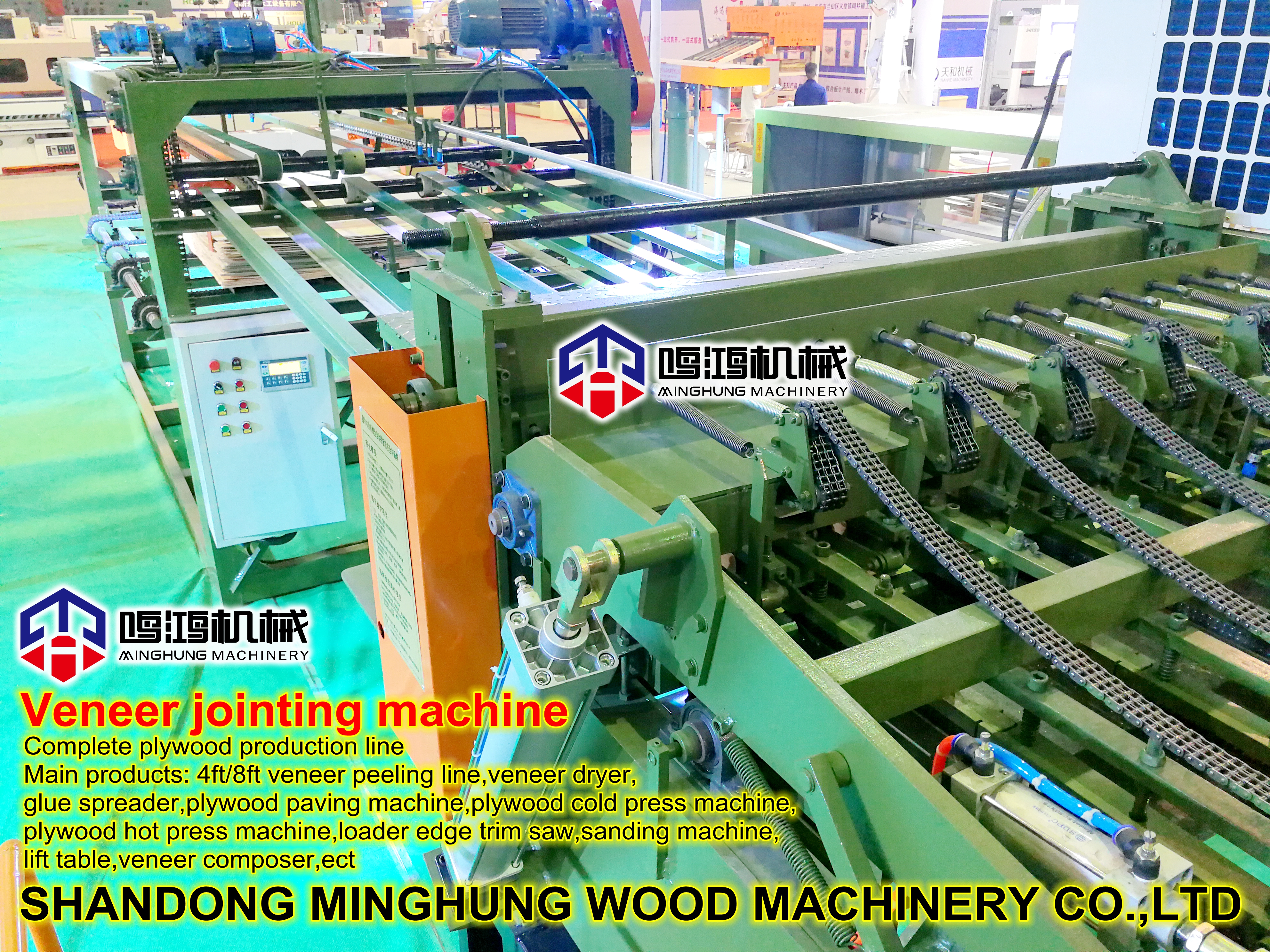

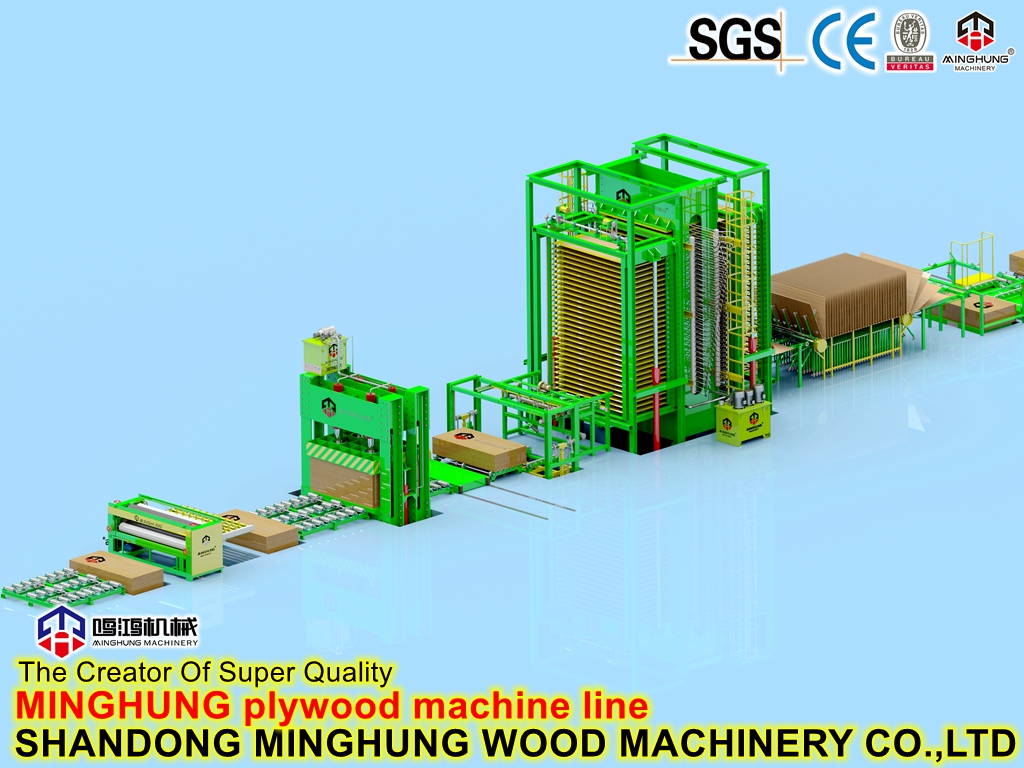

log debarker

weneer peeling machine

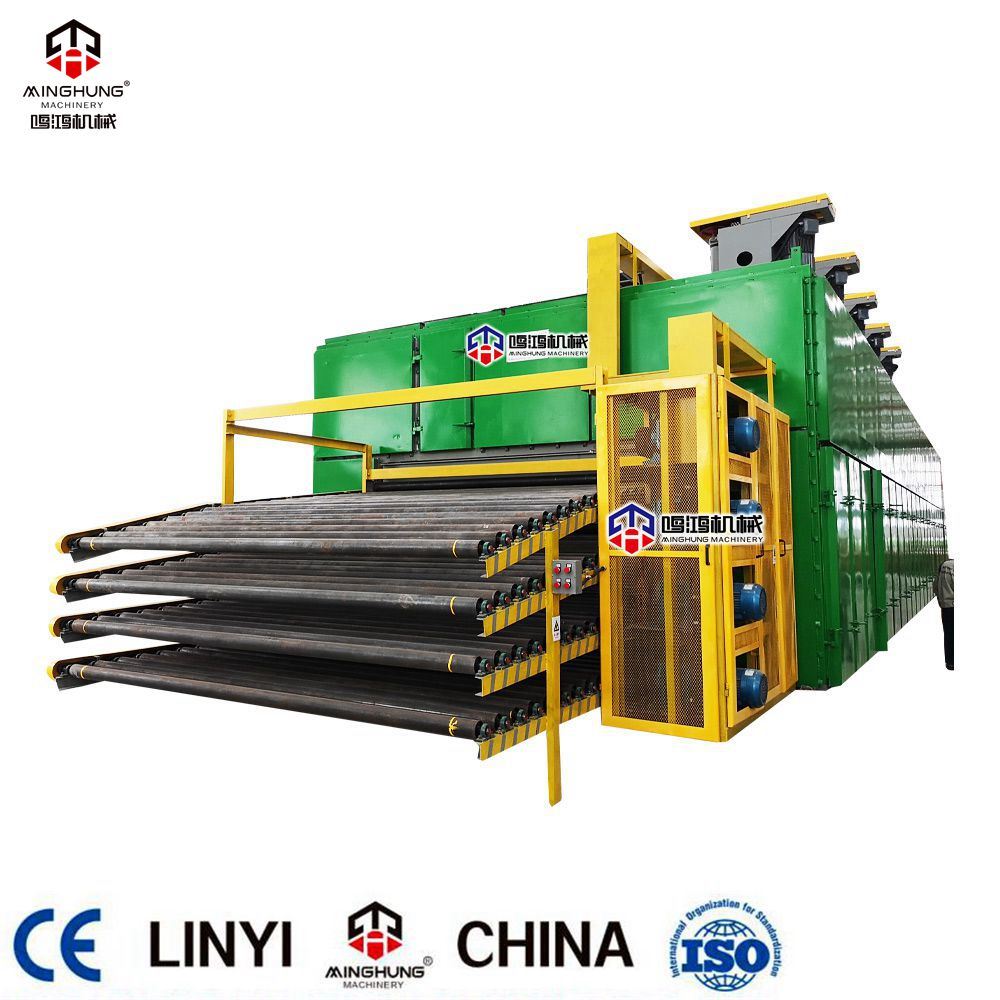

dryer

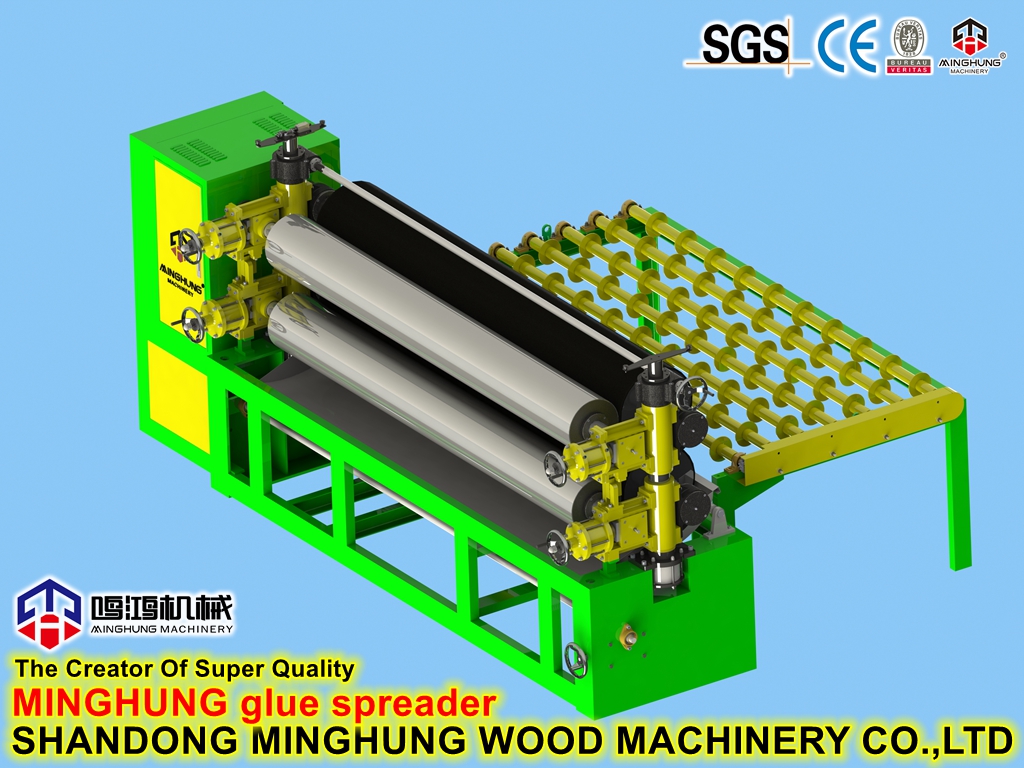

glue spreading

cold press

hot press

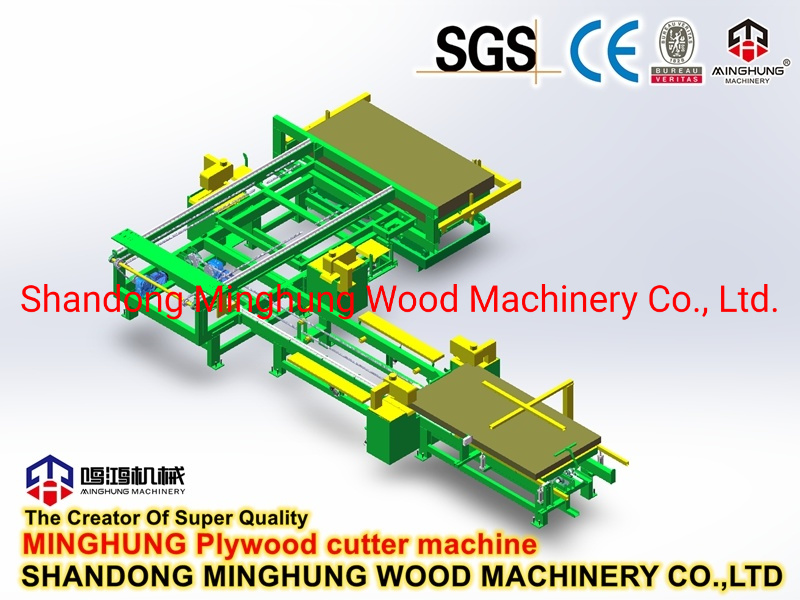

cross-cut saw

sander

Construction & Structural: Roof sheathing, wall sheathing, floor underlayment, concrete formwork (especially film-faced for reuse), I-beam webs, structural paneling for shear walls.

Furniture Manufacturing: Cabinet carcasses, bookshelves, drawer bottoms, table/chair tops, sofa frames, bed bases.

Interior Joinery & Finishing: Wall paneling, ceiling panels, partitions, door cores, substrate for moldings/trim.

Packaging & Transport: Export crates, pallets, shipping containers, display stands.

Vehicle & Marine: RV interior linings, truck body linings, boat decks, bulkheads (requires marine/waterproof type).

Industrial & Craft: Workbench tops, shelving, display boards, musical instrument parts (e.g., guitar backs/sides), model making.

Other: Signage substrates, sporting goods (e.g., skateboards), DIY projects.

Shandong MINGHUNG Wood Based Panel Machinery Co.,Ltd Located in Xiaogezhuang Industrial Zone, Yitang Town, Lanshan District, Linyi City.

MINGHUNG supplies equipment including branch material loading devices, drum chippers, long wood chippers, ring chippers, milling machines, hammer crushers and other complete artificial panel preparation section suppliers. The high-capacity particle super chip machine has unique advantages in the global particle board field. The development of the MINGHUNG system proves that Industry 4.0 has come to the field of artificial boards.

We regularly participate in international industry exhibitions based on the company's business development and customer needs. On one hand, this helps us showcase our company's strength and expand new customers. On the other hand, we visit existing customers for follow-up visits, thereby enhancing the bond between them.

As a leading plywood machinery factory in China, we specialize in assisting our clients in designing rational factory layouts and arranging machine positions. By utilizing our expertise, you can ensure that your plywood factory operates at its highest potential, maximizing productivity and profitability, Contact us today to discuss your plywood production requirements and let us help you create an optimized factory layout that aligns with your goals.

Whatsapp: +8618769900191 +8615589105786 +8618954906501

Email: osbmdfmachinery@gmail.com