Rotary Cut Veneer Manufacturing Machine for Core Veneer Sheets

Ürünümüz 4feet Kaplama üretim hattımız 4feet kütük soyucu, 4feet ahşap soyma makinesi, kütük konveyörü ve 4feet vakumlu kaplama istifleyici içerir.

Ahşap işlemek ve ahşap kaplama üretmek için kaplama soyma hattının işlevi, bildiğiniz gibi, ahşap kaplama kontrplak, ahşap mobilya ve diğerleri yapmak için malzemedir. Bu yüzden kalitesi çok önemlidir. Bu, kaplama makinesinin kaliteli ve yeterince güçlü olmasını gerektirir.

Bu 4 fitlik kaplama üretim hattı, maksimum kütük uzunluğunu 1400 mm ve maksimum kütük çapını 550 mm işleyebilir ve kalınlık 0,5-4 mm olabilir.

Gelişmiş ve olgun üretim teknolojisi ve deneyimli işçiler ve profesyonel teknisyenler ile kaplama makine yapımız ve karakterlerimiz iyidir. Ve iyi ve kalın malzemeler, süper makine aksesuarları, iyi elektrik kutusu ve yükseltilmiş elektrikli parçalar kullanıyoruz, Bu nedenle kütük soyma makinemiz kayın, huş ağacı ve diğerleri gibi sert ağaçları soymak için yeterince güçlüdür ve çok hassas ahşap kaplama üretmenize yardımcı olabilir. çok değer yaratmanıza yardımcı olacak pürüzsüz yüzey.

Kaplama makinesi hakkında daha fazla bilgi için bize hoş geldiniz, sizin için makine çalışma videosu ve detayları sunacağız.

Our product 4feet Veneer production line includes 4feet log debarker, 4feet wood peeling machine, log conveyor, and 4feet vacuum veneer stacker.

The function of veneer peeling line for processing wood and produce wood veneer, as you know, wood veneer is material for making plywood, wooden furniture and others. So its quality are very important. This requires the veneer machine are good quality and strong enough.

This 4feet veneer production line can process max log length 1400mm, and max log diameter 550mm, and thickness can be 0.5-4mm.

With advanced and mature production technology, and experienced workers and professional technicians, So our veneer machine structure and characters are good. And we use good and thick materials, super machine accessories, good electric box and upgraded electric parts, So our log peeling machine are strong enough to peel kinds of hardwood like beech, birch and others, and can help you produce very accurate wood veneer with smooth surface, which will help you create much value.

Welcome contact us for more information of veneer machine, we will offer machine working video and details for you.

|

Veneer Production Line includes: Wood Debarker Veneer Peeling Machine Log Transporter Vacuum Veneer Stacker Knife Grinder

They are necessary machine for producing wood veneer |

1. Wood Debarker

The Function:

Removing wood bark, and make log round.

The Structure:

Wood debarker machine structure is simple, mainly consist by: machine frame, motors, cylinder, hydraulic station, knife

The Working Principle:

When start machine, put log into it, worker shake handle, machine will work.

The Advantages:

|

Specification:

Max length: 4feet/8feet

Max diameter: 500mm/550mm/600mm/700mm

Max speed: 70m/min

Total power: 27.5kw

Weight: 4t

Size: 3800*2200*1500mm

Customize machine according to your needs. |

2. Veneer Peeling Machine

The Function:

Processing log into pieces of wood veneer.

The Structure:

Veneer peeling machine mainly consist by: machine frame, motors, rollers, knife, control box

The Working Principle:

When start machine, adjust wood veneer thickness and width you want by CNC screen, adjust machine diameter and open, put log, then veneer machine will automatically roatry.

The Advantages:

|

Specification:

Max length: 4feet/8feet

Max diameter: 500mm/550mm/600mm/700mm

Max speed: 50-80m/min

Total power: 41.2kw

Weight: 6.8t

Size: 4500*2300*1500mm

Customize machine according to your needs. |

3. Log Transporter

The Function:

Transport log, one connect with wood debarker, another connect veneer peeling machine.

The Advantages:

This is the upgrade one, powerful to convey log, the chain will be fine. |

Specification:

Power: 4.4kw

Weight: 2t/pcs

Size: 3000*1800*1500mm |

4. Vacuum Veneer Stacker

The Function:

Automatic sorting wood veneer, save 2 workers, connect with veneer peeling machine.

The Structure:

Machine frame, lift table, convey belt, fan, electric box

The Advantages:

|

Specification:

4feet

Lifting mode: hydraulic lift

Veneer size: 1270*500-1270mm

Thickness:<3.6mm

Power: 18.55kw

Weight: 2.5t

Size: 6500*2000*2750mm |

5. Magnetic Knife Grinder

The Function:

Grinding knife, make it become sharp again.

The Advantages:

Knife is consumable, after using a while, knife edge will become blunt, if you have this grinding machine, will be conveniently and fast make knife become sharp again. Knife is also very important for peeling good quality wood veneer. |

Specification:

4feet magnetic

Knife length: 1500mm

Table size: 1500*160(200)mm

Power: 4kw

Weight: 800kg

Size: 2800*1000*1000mm

Customize machine according to your needs. |

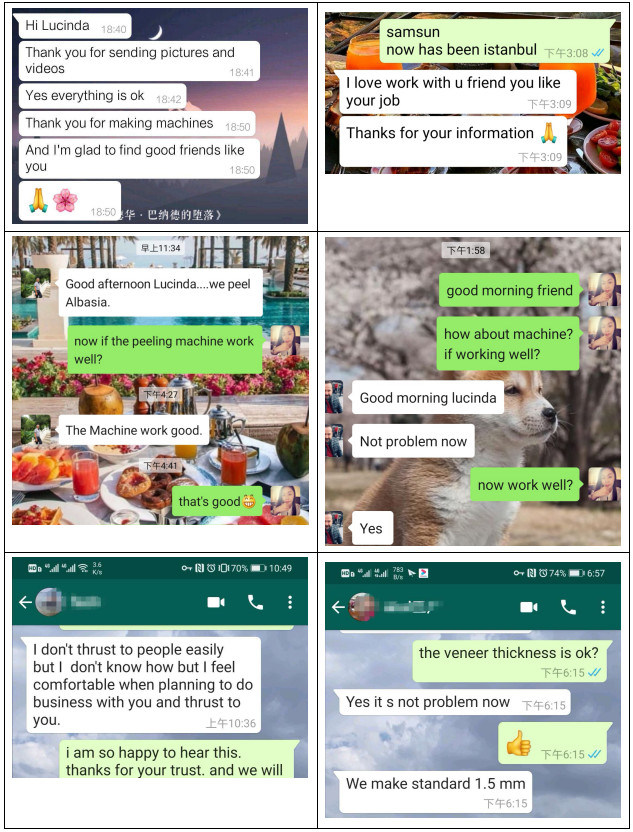

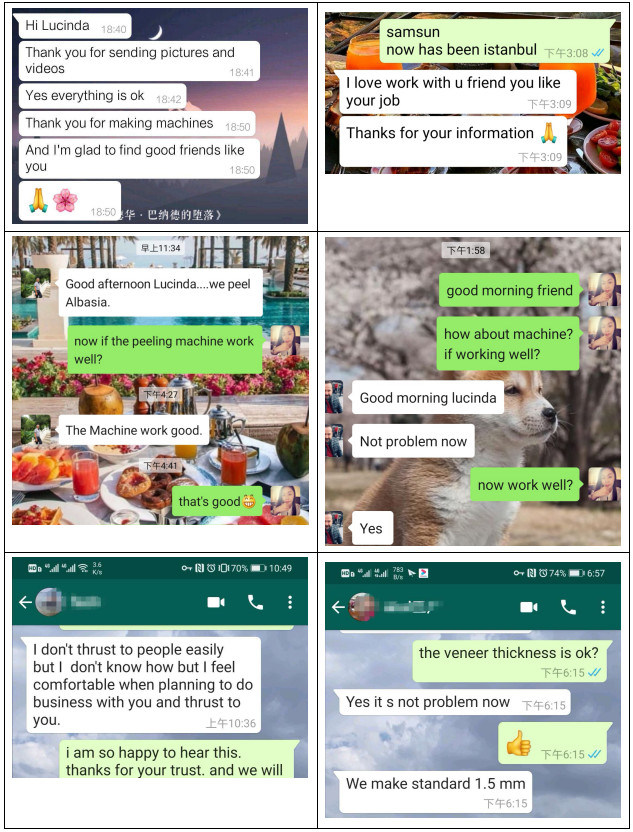

We often talk with our clients about machine working conditions, see if machine is well. If they meet some problems, we will help them solve it in time.

The moment when you choose us, we have been your lifetime partners, anytime you need help, we will be there. Clients Comment:  Delivery:

Delivery:  When machine finish production, we will share test video and pictures to you.

When machine finish production, we will share test video and pictures to you.

When loading, we will send loading pictures to you.

After ship leave, we will offer you container no and ship information, and prepare all documents for your custom clearance. Factory:

Professional manufacturer produce the full sets of veneer machine and plywood machine in Linyi City, Shandong Province, China.

Professional manufacturer produce the full sets of veneer machine and plywood machine in Linyi City, Shandong Province, China.

Including Wood debarker, veneer peeling machine, veneer stacker, veneer dryer machine, glue spreader, cold press machine, hot press machine, plywood saw machine, sanding machine.

The value of our factory is: create much more value for clients.

We have our own morality and principle, insist sincerely treat our clients, regard them as our friend, try help their business. Plywood Machine:

RFQ:

RFQ: | Production Time: |

| 1 month after receive your deposit. |

| Payment Terms: |

30% deposit, 70% before delivery.

100% Letter of Credit. |

| Warranty: |

| 2 years for main parts. |

| MOQ: |

| 1 set |

| Installation: |

| When machine reach your factory, our engineer can go to install |

| After-sales service: |

| Any problem that your worker can not solve, tell us, we will reply you at the first time, |

Contact us:

Whatsapp:

MARK: +8618769900191

ALI: +8615589105786

Lucinda: +8615805493072

Email:

minghungmachinery@gmail.com