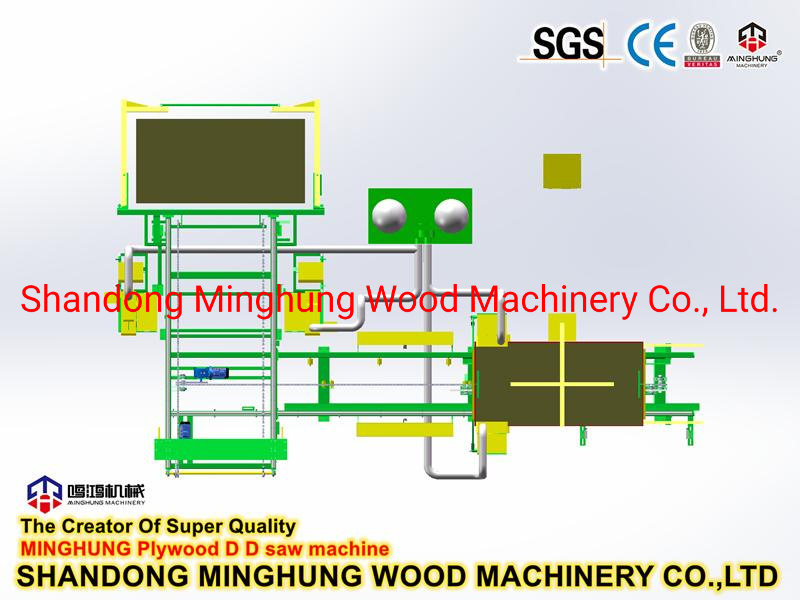

China Top Wood Tree Peeling Machine for Hard Wood Beech Veneer

MINGHUNG powerful wood veneer peeling machine:

Powerful wood peeling machine

Veneer peeling machine

rotary veneer machine

veneer lathe

This is our new upgraded type wood peeling machine, based on our old type, it is improved a lot again. It can easily peel kinds of hard wood like beech wood, birch wood and others, and ensure your veneer quality good.

The veneer machine with hydraulic knife system, so you can easy change blade and no need adjust knife gap and knife height, it will be more conveniently for your workers. And its speed is adjustable, max speed can reach 100m/min, if with stacker, it will be high production capacity; And its body is strong because we use thick materials and through special treatment.

Hydraulic knife system of peeling machine

Hydraulic knife holder of veneer peeling machine

CNC screen of our veneer lathe

High accuracy linear guide

The stick is driven by the transmission system to rotate at a uniform speed, and the speed of the double stick is the same as that of the single stick.

Due to the feed pressure of the knife table, there is a great friction between the log and the stick. The rotation of the stick drives the wood to rotate. During the rotation, the wood is gradually cut into thin slices. The linear velocity of the wood is equal to the linear velocity of the stick.

Since the linear velocity of the stick is constant, the linear velocity of the wood is also fixed. During the cutting process, the diameter of the wood gradually becomes smaller, so the rotational speed of the wood becomes faster and faster. Every time the wood rotates, the radius decreases by a value of the thickness of the veneer. At the beginning, the rotation speed is slow and the radius change rate is small. When the wood is very thin, the rotation speed is very fast, and the radius change rate is very large. The knife table should be fed according to the change of the diameter of the wood. In the early stage of cutting, the speed of the wood diameter change is slow, and the feed speed of the knife table is slow. In the later stage of cutting, the diameter of the wood changes rapidly, and the knife table must also be fed quickly. This requires the feed system of the knife table to adjust the feed speed according to the change process of the wood diameter, resulting in a gradually changing nonlinear feed speed.

Whatsapp: +8618769900191 +8615589105786 +8615805493072

Email: minghungmachinery@gmail.com

Merhaba, Biz ağaç soyma makinesi sunan Çin fabrikasıyız. senin ülkende pek çok insan kayın ağacı gibi sert ağaçları soyar. yeterince güçlü soyma makinesi gerektirir.

Ülkenize çok sayıda ağaç soyma makinesi ihraç ettik. sizin için güçlü makineyi sunabiliriz.

Ayrıca kontrplak makinesi üretiyoruz. sıcak pres makinesi, kaplama kurutma makinesi gibi.

MINGHUNG veneer machine at our clients factory:

We are confident to say that until now, almost all of our clients are very satisfied of our veneer machine and our service, most of them peel hard wood. many of them have bought veneer production line from us again and again.

MINGHUNG veneer machine delivery:

Before loading your veneer lathe, we will first assembly and test it, and share the test video with you, after confirmed all is fine, then we will disassembly and loading for you.

dear friend, if you wants to start produce wood veneer, do not worry, we will support you through offer strong machine, if you wants to enlarge production capacity, do not worry, our machine must will be help you.

our Company Culture: Be an excellent company, makes staff happy, customers satisfied, and gains social recognition.

we are doing this, we are continuous to improve our machine, choose us, you must will be satisfied.

more details, welcome contact us, will reply you in time