Plywood Making Machine Hydraulic Hot Press Machine

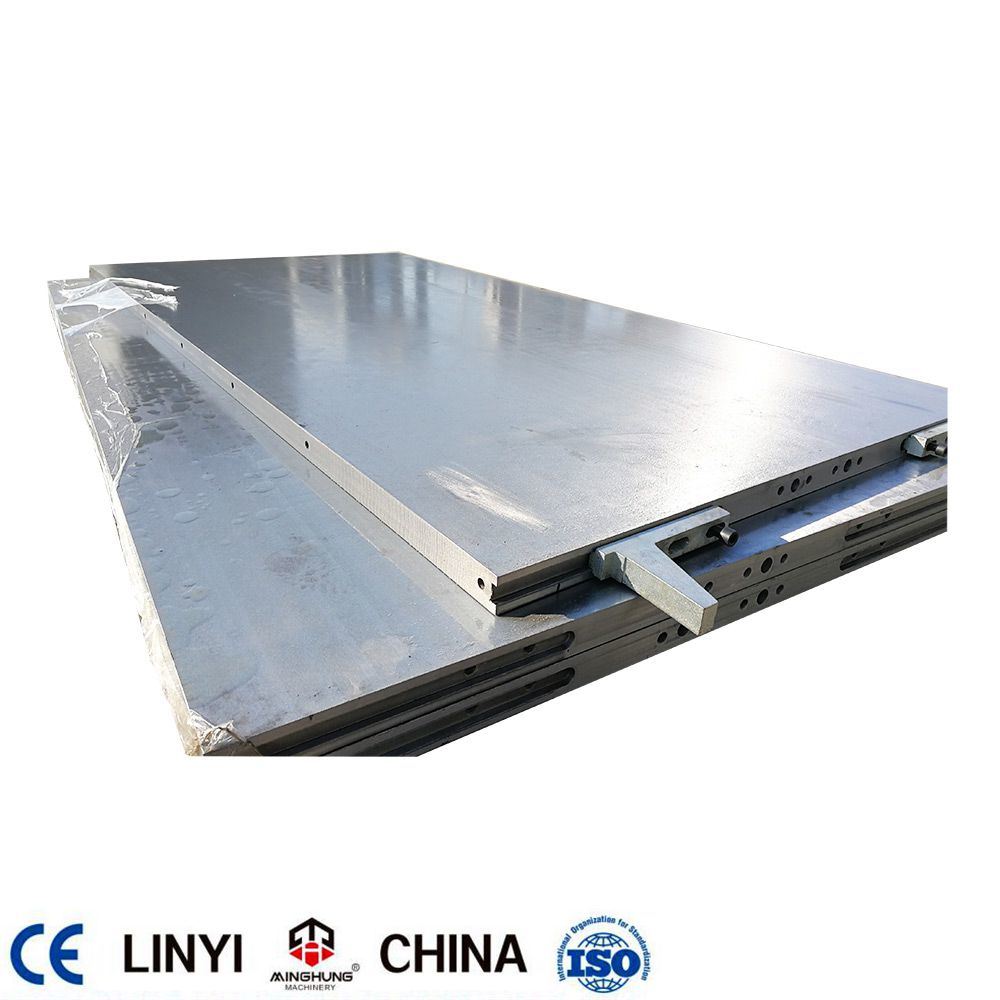

At the same time, the rigidity and strength are high, but the hot-pressed plate is relatively thick; the latter is usually in the form of a thin plate, and due to stress generated during welding and processing, high processing accuracy is required. The hot-pressed plate is thin and easy to preheat and control the temperature, but it has high requirements for the workpiece. The uneven thickness of the workpiece will cause the deformation of the platen and affect the quality of subsequent processing; the thicker hot-pressed plate is beneficial to increase the heat capacity and improve the strength and rigidity. But it will increase the size of the press and consume more steel. During manufacturing and processing, it should be ensured that the flatness of the hot pressing plate and the upper and lower surfaces have sufficient parallelism. The flatness tolerance of the hot pressing plate should be within the range of 0.1-0.18mm, and the tolerance of parallelism should be within the range of 0.15-027mm. The roughness is 3.2 μm. The temperature difference should not exceed 2-3°C in the entire width of the hot pressing plate. If the temperature difference is too large, the moisture content will be uneven, the product will warp easily, and the strength and appearance quality of the product will be affected. The heating channel through which the heat medium flows in the heat press plate is generally not paid attention to by people in the furniture industry. The correct circuit design should be based on the principle of facilitating the flow of heat medium, facilitating the uniform temperature rise of the plate surface, and reducing the leakage of heat medium. For the small press hot plate used in the furniture industry, the design of single channel and double circuit is generally adopted, which can meet the requirements of use.

HOT PRESS MAHCINE

one necessary machine for producing plywood, its pressure and layers will be different according to your plywood thickness, size, and requires.

tell us your conditions and requires, we will offer the most suitable plywood hot press machine for you

>>>SPECIFICATION

| name | hot press machine |

| model | MH-HP15 |

| pressure | 500t |

| cylinder | 360*2pcs |

| layers | 15 |

| power | 29.5kw |

| weight | 33t |

| size | 3600*1370*4500mm |

>>> DELIVERY INFORMATION

1. Payment terms

T/T. 30% as adeposit, 70% before delivery.

2. Production time

one month

3. Warranty

2 years

>>> ADVANTAGES

1. Hydraulic station is one important part for plywood hot press machine, it will offer the oil to cylinder, driving it lift hot press machine.

The hydraulic station is also called the hydraulic pump station. The motor drives the oil pump to rotate. The pump sucks oil from the oil tank and pumps the oil. The mechanical energy is converted into the pressure energy of the hydraulic oil. The hydraulic oil is realized by the hydraulic valve through the integrated block (or valve combination). After the flow adjustment, it is transmitted to the oil cylinder or oil motor of the hydraulic machinery through the external pipeline, thereby controlling the direction change of the hydraulic motor, the size and speed of the power, and promoting various hydraulic machinery to do work.

2. The oil cylinder is treated with anti-rust, alloy casting, high hardness, scratch resistance, suitable for high-strength operations, and uses a good oil seal to prevent leakage, ensure the pressure in the oil cylinder, and good performance

3. Usually hot platen use 42mm or 52mm, The hot platen be processed by large lathe, make the surface is smooth, with sufficient strength and stiffness. It does not deform at high temperatures, and the temperature and heat are uniform. This makes the plywood heated evenly, the surface is flat, and the thermal efficiency is high, which improves the production efficiency.

>>> our factory

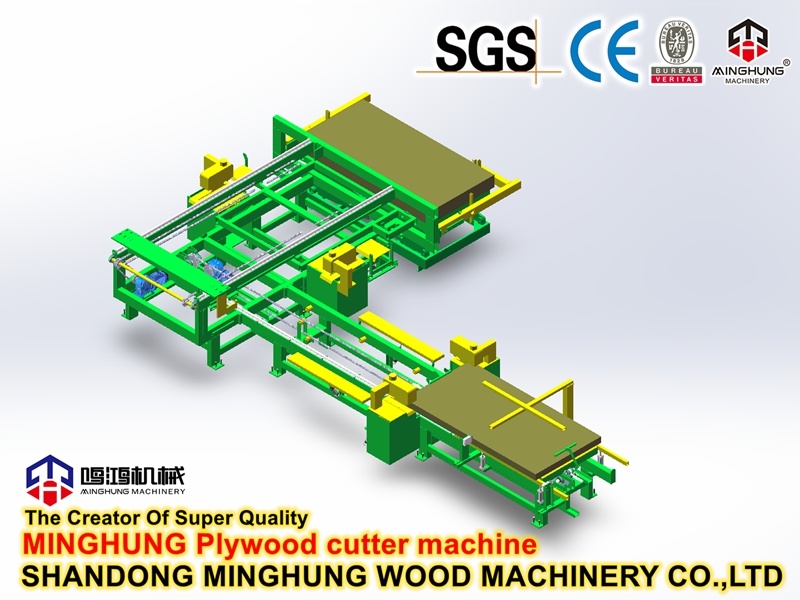

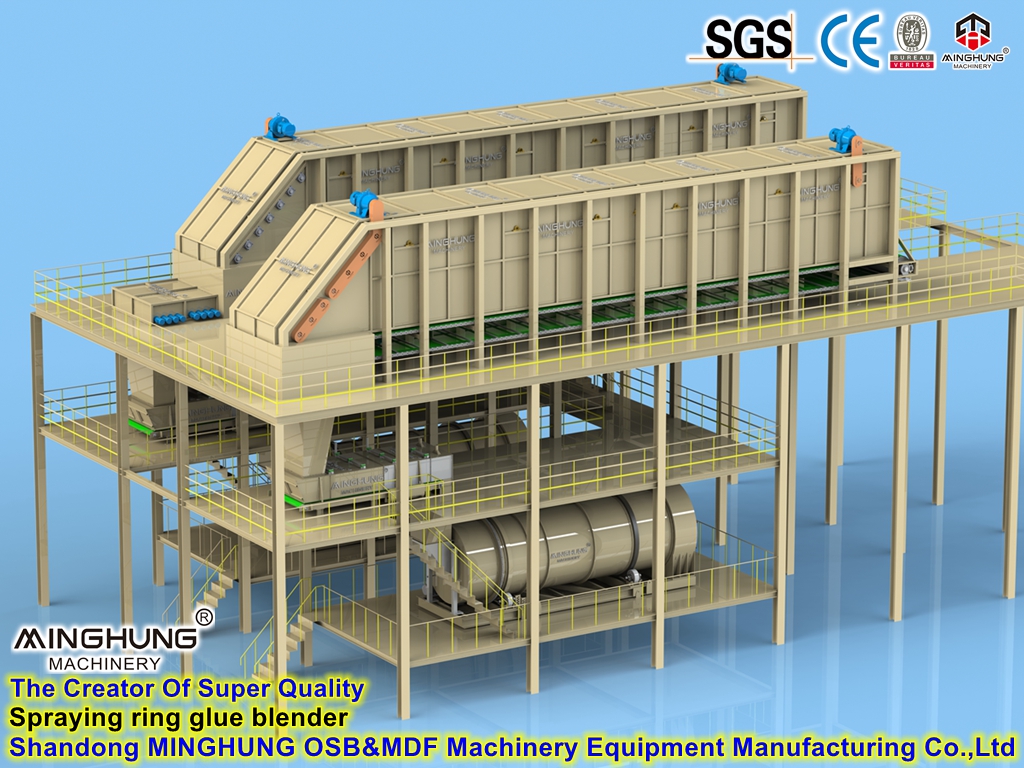

Our main products include wood log debarker, veneer peeling machine, vacuum veneer stacker, veneer dryer machine, plywood cold press machine, plywood hot press machine, glue spreader, glue mixing machine, automatic plywood veneer paving line, plywood saw machine, sanding machine.

Scientific and technological innovation oriented, quality-based, service supremacy, we offer full complete range of plywood production solution and technology support for our customers. Yet our machines have been exported more than 30 countries and regions like Russia, Poland, Ukraine, Portugal, Bulgaria, Romania, Turkey, Egypt, Morocco, Indonesia, etc, and get good feedback.

With high efficiency sales team offer 24 hours online service, the professional technical team and after-sales service team offer plant layout, machine drawings, and after-sales service.

Choose us, you need not worry anything, we will help you arrange all.

>>> DELIVERY

before delivery, our engineer will test machine for make sure machine in good conditions.

when loading machine, we will share the loading pictures with you.

after ship leave, we will send ship information to you.

and prepare all documents for you do custom clearance.

>>> CONTACTS

At the same time, the rigidity and strength are high, but the hot-pressed plate is relatively thick; the latter is usually in the form of a thin plate, and due to stress generated during welding and processing, high processing accuracy is required. The hot-pressed plate is thin and easy to preheat and control the temperature, but it has high requirements for the workpiece. The uneven thickness of the workpiece will cause the deformation of the platen and affect the quality of subsequent processing; the thicker hot-pressed plate is beneficial to increase the heat capacity and improve the strength and rigidity. But it will increase the size of the press and consume more steel. During manufacturing and processing, it should be ensured that the flatness of the hot pressing plate and the upper and lower surfaces have sufficient parallelism. The flatness tolerance of the hot pressing plate should be within the range of 0.1-0.18mm, and the tolerance of parallelism should be within the range of 0.15-027mm. The roughness is 3.2 μm. The temperature difference should not exceed 2-3°C in the entire width of the hot pressing plate. If the temperature difference is too large, the moisture content will be uneven, the product will warp easily, and the strength and appearance quality of the product will be affected. The heating channel through which the heat medium flows in the heat press plate is generally not paid attention to by people in the furniture industry. The correct circuit design should be based on the principle of facilitating the flow of heat medium, facilitating the uniform temperature rise of the plate surface, and reducing the leakage of heat medium. For the small press hot plate used in the furniture industry, the design of single channel and double circuit is generally adopted, which can meet the requirements of use.

Whatsapp: +8618769900191 +8615589105786 +8615805493072

Email: minghungmachinery@gmail.com

Website: www.plywoodmachineline.com