The entire line can be divided into four modules: 1. Bamboo Processing Equipment; 2. Wood Processing Equipment; 3. Gluing & Layup Equipment; 4. Pressing & Finishing Equipment.

Module 1: Bamboo Processing Equipment

This is the core section that differentiates it from ordinary plywood lines, designed to process round bamboo poles into standardized curtains/mats.

1. Bamboo Cross-Cut Saw: Precisely cuts long bamboo poles into required process lengths.

2. Bamboo Splitter: Splits the bamboo sections radially into strips of equal width.

3. Bamboo Knot Remover/Planer: Removes internal and external bamboo nodes and planes the strips into slivers with uniform thickness and smooth surfaces.

4. Bamboo Curtain/Mat Weaving Machine: Automatically weaves the processed bamboo slivers into curtain or mat forms using nylon thread.

5. Bamboo Dryer: Typically a Mesh Belt Dryer, reduces the moisture content of the woven curtains/mats to the optimal level (8%-12%) for hot pressing, preventing deformation.

Module 2: Wood Processing Equipment

This section is similar to standard plywood lines, producing wood veneer for the core layer.

1. Log Debarker: Removes bark from logs.

2. Peeling Lathe: Peels debarked logs into continuous, uniform-thickness wood veneers. High-precision CNC lathes are required.

3. Veneer Dryer: Commonly a Roller Dryer, rapidly dries wood veneers using hot air.

4. Veneer Clipper & Patching Machine: Cuts dried veneers to size and automatically patches defects to improve yield.

Module 3: Gluing & Layup Equipment

This module integrates the bamboo and wood materials for pressing.

1. Glue Mixing & Supply System: Continuously and automatically prepares and supplies adhesive.

2. Dual-Purpose Glue Spreader: Applies adhesive evenly to both wood veneers and bamboo curtains/mats. Dipping machines or special spreaders ensure glue penetrates the curtain mesh.

3. Composite Layup Line: Automatically assembles the glued materials into a mat according to a preset structure (e.g., Bamboo Face + Wood Veneer Core + Bamboo Back).

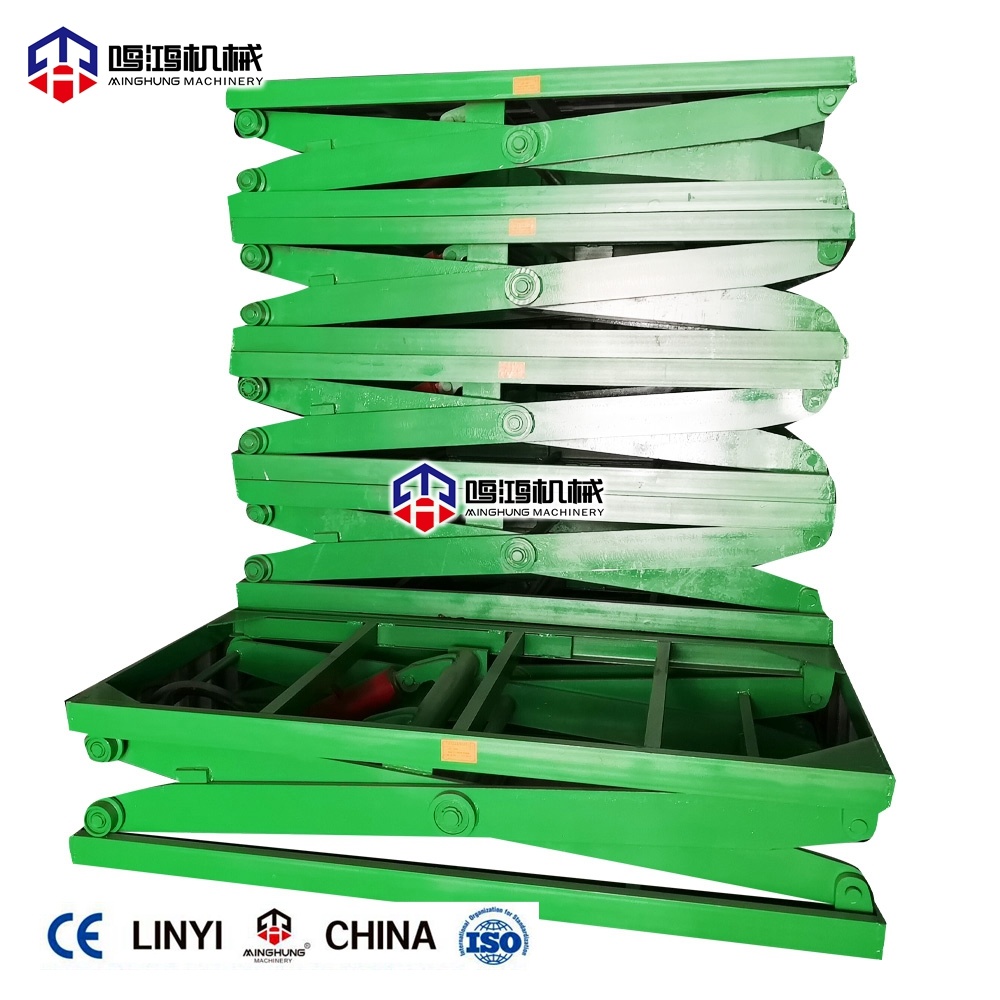

4. Pre-Press: Applies cold pressure to the mat for initial bonding strength, facilitating safe transfer to the hot press.

Module 4: Pressing & Finishing Equipment

This module gives the panel its final properties and dimensions.

1. Hot Press (Core Equipment)-Continuous Press:

The most advanced option. The mat enters continuously, is pressed and cured between heated steel belts while moving. Offers high output, superior surface flatness, precise thickness control, and energy efficiency.

2. Cooling & Turning Stacker: Cools the hot panels and stacks them neatly to release internal stress.

3. Calibrating Sander: A heavy-duty wide-belt sander that sands panels to a consistent thickness and smooth surface.

4. Cross-Cut & Rip Saws: CNC-controlled saws that trim panels to the final customer dimensions with high precision.

5. Central Control System: The "brain" of the line. Monitors and controls all equipment parameters from a central control room for intelligent, stable production.