|

Product Equipment

| Stage 1: Raw Material Preparation & Handling Section |

1. Chipper

To chip wood (small-diameter logs, wood residuals, etc.) into uniform process chips.

Requirement: High capacity and stable operation to meet daily high-intensity raw material processing demands.

2. Chip Screen & Re-crusher

To screen chips, removing oversized and undersized fragments, ensuring consistent chip size for the next stage. This is the foundation for producing high-quality fibers.

3. Chip Storage & Metering System

To store qualified chips and feed them continuously and steadily into the preheating & digesting system according to a preset ratio.

| Stage 2: Fiber Preparation & Flame Retardant Treatment Section (Fireproof Core) |

4. Preheating & Digester

To soften and preheat the chips with steam, making them easier to separate into fibers.

5. Refiner

One of the core equipment. It defibrates the chips into fine wood fibers under high temperature and pressure. Its quality directly determines the mechanical properties of the board.

6. Blending & Flame Retardant System (Critical System)

This is the most critical step for producing fire-resistant MDF.

Resin Blending: To precisely apply adhesive (typically modified Urea-Formaldehyde or Melamine-Urea-Formaldehyde resin) to the fibers.

Flame Retardant Application: To apply liquid or powder flame retardants (e.g., ammonium phosphate, boron compounds) simultaneously or separately, but evenly, onto the fibers along with the resin. High-speed rotary blenders are typically used.

Requirement: Mixing must be extremely uniform to ensure each fiber is coated with the retardant, guaranteeing consistent and durable fire performance.

7. Fiber Drying System

To dry the resin and retardant-coated fibers to an appropriate moisture content.

Note: Drying temperature and time must be precisely controlled to prevent premature reaction of the retardant or resin.

| Stage 3: Forming & Pre-pressing Section |

8. Air-Flow Forming Machine

To evenly distribute the dried fibers into a continuous, consistent-thickness mat. Forming uniformity affects the density distribution and thickness tolerance of the board.

9. Pre-press

To apply cold pre-pressing to the fluffy mat, giving it initial strength for easier handling and reducing the opening height of the hot press, thereby improving production efficiency.

10. Mat Scale & Metal Detector

To scan the mat for density distribution and detect metal contaminants, protecting the expensive continuous press from damage.

| Stage 4: Hot Pressing & Post-processing Section |

11. Continuous Hot Press

The heart of the production line. The mat is subjected to high temperature and pressure, curing the adhesive and bonding the fibers into a solid board. For a capacity of 600 m³/day, a Continuous Flat Press is essential. Its precise control of pressure, temperature, and speed is key to producing stable-quality 12mm thick boards.

12. Cooler & Turner

To evenly cool the high-temperature boards after pressing, preventing warping and completing the curing process.

13. Cut-to-Size & Stacking System

To saw the continuous board into required sizes (e.g., 4ft x 8ft) and stack them automatically.

14. Conditioning Area

To allow the boards to rest for 24-48 hours, allowing internal stresses and moisture content to equilibrate, which benefits subsequent processing.

| Stage 5: Sanding & Inspection/Packaging Section |

15. Double-Dimension Wide-Belt Sander

To perform precision sanding on the top and bottom surfaces of the boards, ensuring accurate thickness and a smooth, flat surface ready for laminating or direct use.

16. Fire Performance Testing Equipment (Optional but Important)

To conduct sample tests on finished boards to verify their fire rating (e.g., compliance with ASTM E84, EN 13501-1).

17. Automatic Packaging & Palletizing System

To package (e.g., shrink-wrapping) and palletize the finished boards for storage and shipping.

| Summary of Production Line Core Advantages |

High Capacity & Efficiency: Designed for 600m³/day output, meeting large-scale order demands.

Excellent Fire Resistance: Professional fiber-level flame retardant application system ensures products meet international fire standards.

Precision Control: Fully automated line control ensures consistent quality and high yield for 12mm thick boards.

High Reliability: Core equipment (e.g., continuous press, refiner) adopts mature and reliable technology, ensuring continuous and stable operation.

|

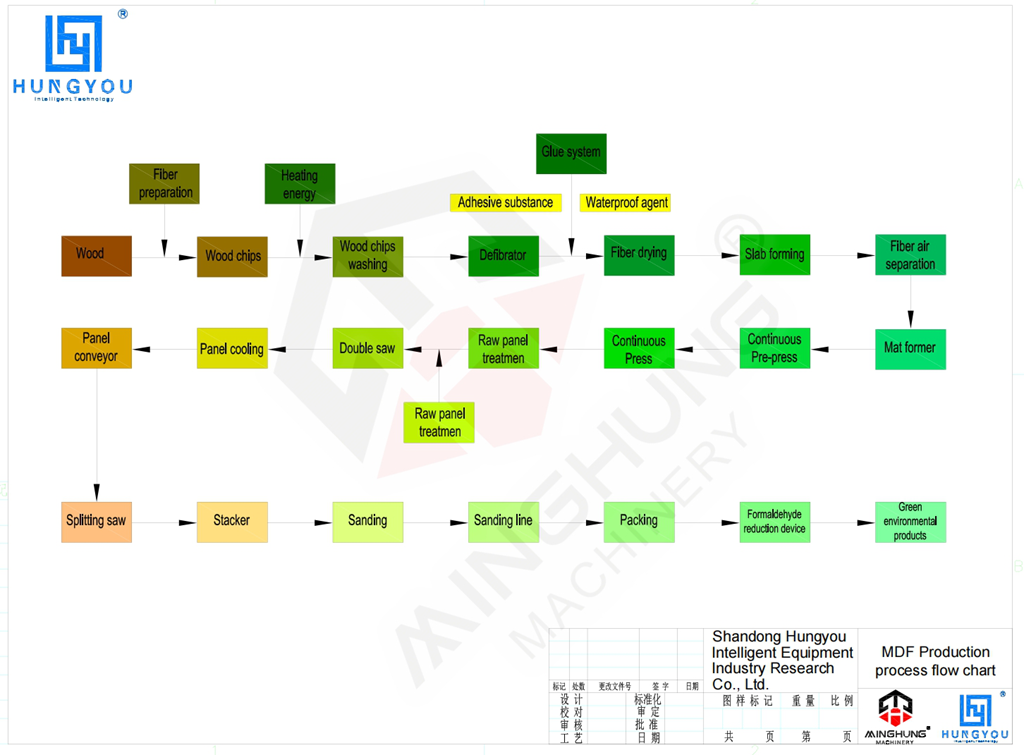

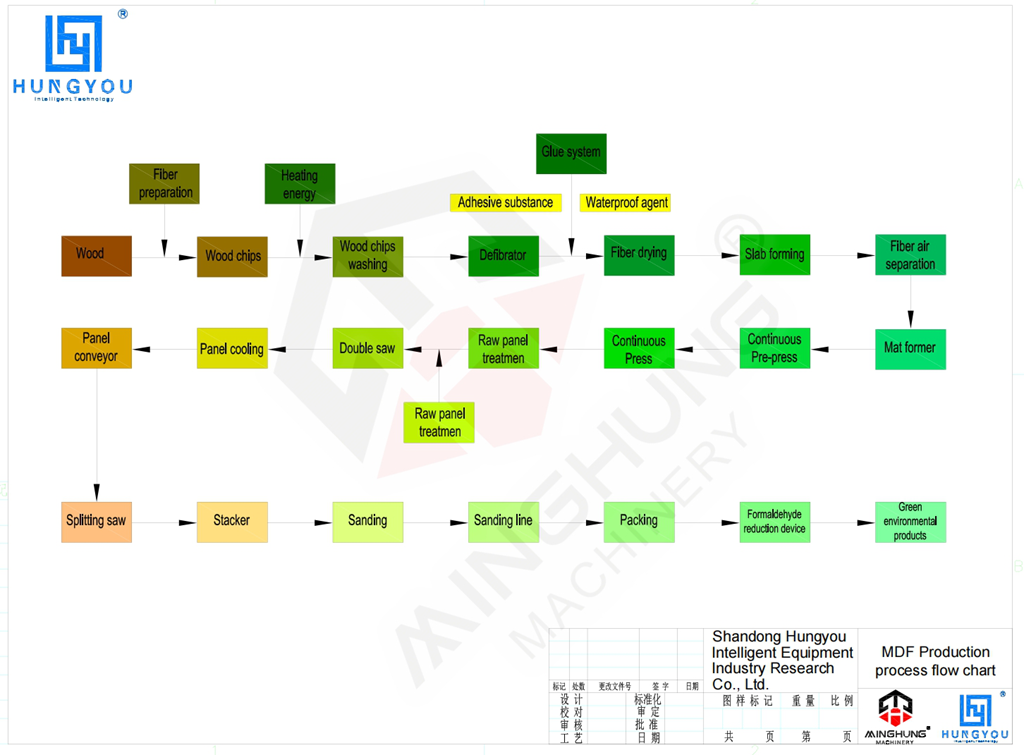

Product Process

The production of fire-retardant MDF board is based on the standard MDF manufacturing process, with the key addition of fire retardants. The complete production workflow is as follows:

1. Raw Material Preparation:

Wood raw materials, such as small-diameter logs, branches, and wood processing residues, are used and broken down into uniformly sized wood chips.

2. Fiber Preparation (Core Stage):

Digesting: The wood chips are fed into a digester and softened using high-pressure steam.

Refining: The softened chips are then separated into individual wood fibers in a defibrator (refiner).

Blending with Resin and Fire Retardant (Critical Step): During the refining process, urea-formaldehyde resin (or other environmentally friendly binders) and liquid or powder fire retardants are evenly applied to the fibers. The fire retardant is the key component that imparts fire-resistant properties, typically acting through chemical mechanisms to inhibit or delay combustion.

3. Drying:

The fibers, now coated with resin and fire retardant, are conveyed through a drying pipeline where hot air dries them to an appropriate moisture content.

4. Mat Forming:

The dried fibers are spread evenly onto a conveyor belt using an air-layering or mechanical forming machine to create a continuous, uniform "fiber mat." The amount of fiber spread is precisely controlled to achieve the target 12mm thickness.

5. Pre-pressing and Mat Handling:

The fluffy fiber mat is first compressed by a pre-press to give it initial strength for easier handling and cutting.

Afterwards, the mat is trimmed to the required dimensions by edge saws.

6. Hot Pressing (Key to Forming):

The mat is sent into a multi-opening hot press or a continuous press. Under high temperature (e.g., 180-210°C) and high pressure (e.g., 20-30 kg/cm²), the resin in the fibers cures rapidly, bonding the loose fibers into a dense board. The pressing time and pressure are precisely controlled for a 12mm thick board.

7. Cooling and Conditioning:

The newly pressed boards are very hot and must pass through a cooling system to stabilize their internal structure.

After cooling, the boards are stacked for a period of "conditioning" or "curing" to allow internal stresses and moisture content to equilibrate, achieving optimal performance.

8. Sanding and Cutting:

The conditioned boards are sanded by a wide-belt sander to ensure precise thickness (e.g., 12mm) and a smooth, flat surface.

Finally, the large panels are cut to final standard sizes (such as 1220mm x 2440mm) according to customer requirements.

9. Quality Inspection and Packaging:

The finished boards undergo strict quality control checks, including tests for thickness, density, modulus of rupture (MOR), and fire rating compliance .

After passing inspection, the boards are packaged and stored for shipment.

|

Main Application of 12mm Fire-Retardant MDF

12mm thick fire-retardant MDF is widely used due to its balanced structural strength, excellent workability, and crucial fire safety properties. Here are its primary

I. Commercial and Public Space Decoration (Core Application Area)

These venues have mandatory or high-standard requirements for fire ratings, making them the primary market for fire-retardant MDF.

1. Hotels & Hospitality:Wardrobe doors in guest rooms, bathroom vanity bases, feature walls, custom furniture (e.g., desks, TV consoles), decorative moldings.

2. Office Buildings & Meeting Rooms:Partition walls, office furniture (e.g., desktops, cabinets), wall panels, suspended ceilings, display cabinets.

3. Schools, Hospitals, Libraries:Desks, laboratory furniture, hospital ward furniture, lockers, bookshelves, reception desks.

4. Shopping Malls, Restaurants, Exhibition Halls:Shop partitions, display props, decorative wall cladding, fixed seating bases, signboard substrates.

II. Transportation Industry

Ships, high-speed trains, and subways have extremely high requirements for material flammability.

Interior paneling for train/subway carriages (e.g., wall panels, luggage rack bases), ship cabin interiors, cabinet doors.

III. Specific Residential Areas

While standard MDF is common in homes, fire-retardant MDF is a safer choice for critical areas.

1. Kitchens:Cabinet carcasses and doors, especially near stoves.

Advantages: Provides a layer of fire protection against accidental sparks or overheating.

2. Entertainment Rooms / Home Theaters:Custom media walls, speaker cabinets, projector wall surrounds.

3. Garages or Workshops: Storage cabinets, workbenches.

IV. Other Professional Applications

Electronics Industry: Used for test fixtures, equipment liners. Anti-static versions (if required) protect sensitive components.

Door Manufacturing: Used as the core material for interior doors, overlaid with a decorative surface, providing a flat, stable, and fire-resistant product.

Summary and Key Advantages

The main drivers for choosing 12mm fire-retardant MDF are the combination of "Safety" and "Functionality":

Safety: Effectively delays combustion in case of fire, buying crucial time for evacuation and firefighting.

Decorability: Like standard MDF, it has a perfectly smooth surface ideal for secondary processing like laminating, painting, milling, and carving, meeting various design needs.

Structural Strength: 12mm is a medium thickness offering a good balance of strength, weight, and cost, making it suitable for furniture manufacturing and interior decoration.

|

Comment & FAQ

Q:Are you a factory or a trading company?

A:We are an industry and trade integrated company with 40 years of experience.

Q:How to choose the right machine?

A:We will check and confirm the type of furniture you manufacture, the process used and the size of the board to recommend the most suitable machine to you.

Q:Can you customize products for customers?

A:Yes, we can customize products according to customer requirements or drawings. At the same time, we protect customers' business privacy with the strongest awareness.

Q:What payment methods do you offer?

A:Usually T/T and LC. If you have other payment methods, we can also consider it.

|

Company Profile

We are Shandong MINGHUNG Wood Based Panel Machinery Co.,Ltd China factory and manufacturer of full sets of Plywood machinery and Veneer machinery.

The machinery we produce includes peeling machines, chipping machines, rotary cutting machines, drying machines, gluing mixers, laying machines, pre-pressing machines, hot pressing machines, cooling machines, longitudinal and transverse sawing machines, sanding machines, as well as auxiliary machinery such as automatic feeding and discharging systems and lifting platforms.

|

Production department

We regularly participate in international industry exhibitions based on the company's business development and customer needs. On one hand, this helps us showcase our company's strength and expand new customers. On the other hand, we visit existing customers for follow-up visits, thereby enhancing the bond between them.

We provide global installation support and technical training, 2-year machine warranty, and 24-hour online response - let your fiberboard production enter a new era of intelligence and low carbonization.