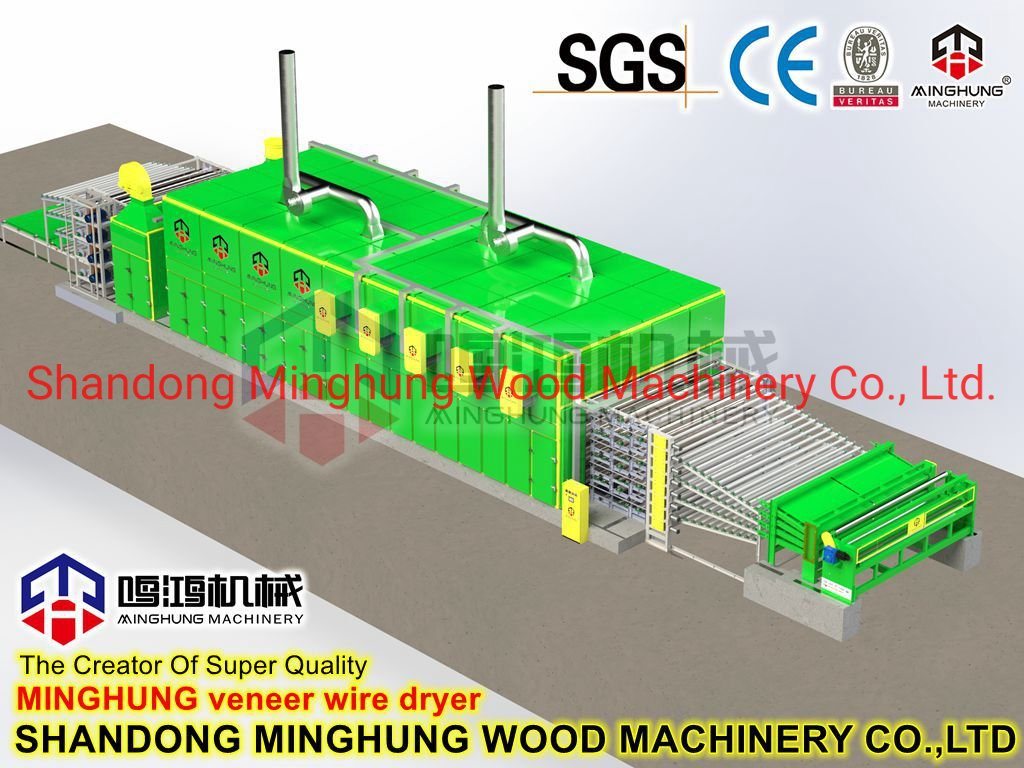

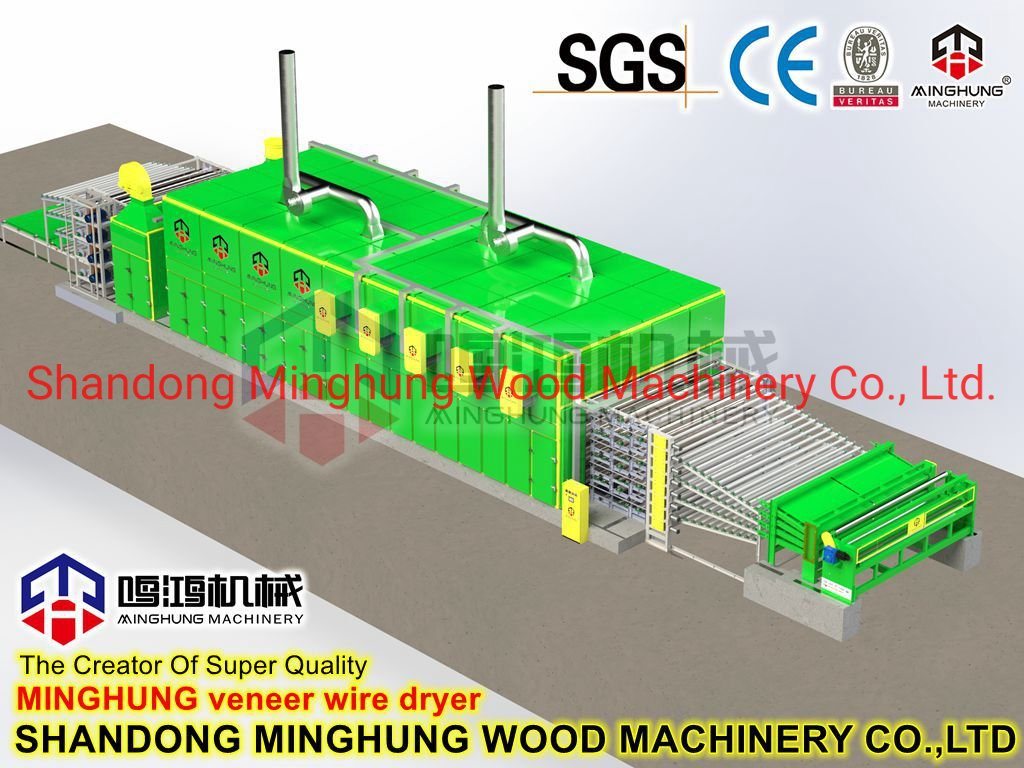

Presenting our state-of-the-art façade drying frames, designed to meet the highest guidelines in the industry. With our expert hardware you can guarantee a flawless and proficient drying process for your ve neer drying.

Our façade veneer dryer systems feature state-of-the-art technology which sets them apart from the competition. Equipped with cutting-edge temperature and muffle control, it delivers precise, reliable drying conditions for clockwork-like results.

With maximum efficiency in mind, the spacious drying chamber is designed to accommodate large quantities of veneer. The frame's keen airflow innovations guarantee an even transfer of strength, eliminating any risk of uneven drying or twisting.

Health is paramount in our program and our façade drying frames are no exception. It is equipped with state-of-the-art sensors and warnings to screen and prevent any anticipated risks, allowing you to enjoy true peace of mind throughout your drying system.

Furthermore, our framework is undeniably easy to use, including natural dashboards that consider simple activities and observations. With its easy-to-understand interface, you can easily change settings and track the progress of veneer drying.

Putting resources into our exterior wall drying frames means putting resources into the life and nature of your veneer dryer project. With its proficient grade highlights and solid execution, it's ideal for organizations looking to upgrade their veneer dryer process.

Choose our veneer dryer frame and experience the highest level of amazing skill and efficiency in your plywood making. Trust our capabilities and let us help you achieve perfect results again.

>>>Parameters:

The dryer machine-Roller dryer, can be different layers, length and width, so we usually offer and produce according to your production capacity required.   |

| Name | Roller dryer |

| Model | MH-RD2830L |

| Heating mode | Steam/Oil |

| Veneer thickness | 1-3mm |

| Transport mode | Roller press mode |

| Speed | Speed adjustable |

| Number of layers | 2 layers/3layers/4layers |

| Length of hot wind area | 20m/26m/30m |

| Peoduction capacity | 10-20m³/day, 20-30m³/day, more |

>>>Main Parts:

Dryer Design:

The installation of veneer roller dryer is more complex and spend longer time than others, so our engineer will go to install with your workers.

>>>Clients:

With our clients, we not just partners, we are friends.

We will stand your position think about problem, consider how to save cost for you, and offer the better and suitable plywood machine to you.

>>>Delivery:

When loading, we will share loading pictures to you.

After ship leave, we will offer you container and ship information.

Offer all documents for you do custom clearance.

>>>Factory:

Shandong MINGHUNG Wood Machinery Co.,Ltd is one famous manufacturer of plywood machine in China, located in Linyi city. Our products have acquired EU CE, ISO 9001, ISO 14001, CCEP, and Energy Conservation Certification.

Our company integrates design, research and development, production and sales, and works closely with China's advanced scientific research institutions. We have a strong research and development team, at present, our machinery has won a number of national patents.

Pay more attention to machine details, details determine sucess or failure, so we continuous improve and optimize machines' performance, strictly control each production step, using advanced lathe processing machine, and through many times inspections, make sure our machine accurate and durable.

Scientific and technological innovation oriented, quality-based, service supremacy, we offer full complete range of plywood production solution and technology support for our customers. Yet our machines have been exported more than 30 countries and regions like Russia, Poland, Ukraine, Portugal, Bulgaria, Romania, Turkey, Egypt, Morocco, Indonesia, etc, and get good feedback.

Our main products include wood log debarker, veneer peeling machine, vacuum veneer stacker, veneer dryer machine, plywood cold press machine, plywood hot press machine, glue spreader, glue mixing machine, automatic plywood veneer paving line, sanding machine.

With high efficiency sales team offer 24 hours online service, the professional technical team and after-sales service team offer plant layout, machine drawings, and after-sales service.

Choose us, you need not worry anything, we will help you arrange all.

we will offer you the better and suitable machine, two years warranty, professional technical team at your service anytime. and hope that build a good and long-time cooperation.

>>>RFQ:

| Production Time: |

| 1 month after receive your deposit. |

| Payment Terms: |

30% deposit, 70% before delivery.

100% Letter of Credit. |

| Warranty: |

| 2 years for main parts. |

| MOQ: |

| 1 set |

| Installation: |

| When machine reach your factory, our engineer can go to install |

| After-sales service: |

| Any problem that your worker can not solve, tell us, we will reply you at the first time, |

>>> Contacts:

Whatsapp: +8618769900191 +8615589105786 +8615805493072

Email: minghungmachinery@gmail.com

Website: www.plywoodmachineline.com