1. Equipment Overview and Design Objectives

The Efficient Peeling Machine for Small-Diameter Logs is a modern wood processing equipment specifically designed to handle small-diameter logs (typically in the range of 30mm - 200mm), branch wood, and the remaining cores from larger peeling machines.

Core Design Objective: To address the pain point that traditional large peeling machines cannot effectively process small-diameter wood. It efficiently peels previously considered waste or low-value fuel—like small-diameter logs and scraps—into high-quality veneer with commercial value, thereby significantly improving comprehensive wood utilization rates and creating additional profit for production enterprises.

Key Feature: Compared to traditional spindle-type peeling machines, it typically adopts a spindleless design and emphasizes automation, high efficiency, and the ability to adapt to irregularly shaped wood.

| 2. Core Working Principle: Spindleless Double-Roller Drive |

This is the most fundamental difference between small-diameter log peeling machines and traditional equipment.

Traditional Spindle Peeling Machine: Relies on large spindles at both ends piercing and clamping the log section to drive its rotation. This makes centering difficult for small, bent, or irregular logs, and the spindles themselves damage and waste part of the wood.

Efficient Peeling Machine for Small-Diameter Logs (Spindleless Type):

1. Dual-Roller Friction Drive: The machine is equipped with two parallel, co-rotating drive rollers (usually rubber-covered rollers).

2. Clamping and Driving: The small-diameter log is placed between these two drive rollers. It is clamped and driven by the friction between the rollers and the wood surface.

3. Free Centering: Without the constraint of fixed spindles, the wood can automatically find and stabilize around its own "natural center of rotation" during rotation. This is particularly effective for bent or irregular wood, maximizing the reduction of debris after peeling and improving the yield.

4. Cutting Motion: Synchronized with the wood's rotation, the peeling knife on the tool rest performs a linear feed motion, peeling the wood into a continuous veneer ribbon.

| Typical Work Process |

1. Loading: Small-diameter logs, cores, etc., are placed onto the front rollers of the machine manually or via an automatic feeding device.

2. Startup and Clamping: The operator starts the machine. The dual drive rollers begin rotating, pulling the wood in and clamping it frictionally.

3. Automatic Peeling: The wood begins to rotate. The tool rest automatically feeds according to the preset thickness value, commencing the peeling process.

4. Veneer Conveyance: The peeled veneer ribbon is smoothly guided out by discharge rollers or guides at the rear of the machine, potentially connected to a reeling device or clipper.

5. Completion and Reset: When the wood is peeled down to the minimum diameter (can be as small as 30-40mm), the tool rest rapidly retracts, the drive rollers stop or reverse, and the remaining core or small piece falls away.

6. Cycle: The machine prepares for the next peeling cycle. Cycles are very short, ensuring high efficiency.

| Main Components |

Sturdy Frame: Provides rigid support for the entire equipment, ensuring stable peeling operation.

Dual Drive Roller System: The core driving component, providing powerful frictional drive force.

Precision Tool Rest Assembly: Includes the knife carriage, peeling knife, and pressure bar (ensures smooth veneer separation without splitting).

Feed System: Often uses a servo motor and ball screw to achieve precise, stepless adjustment of veneer thickness.

Electrical Control System: The core comprises a PLC and a touchscreen HMI (Human-Machine Interface) for setting parameters like thickness and speed. Operation is simple and intuitive.

Hydraulic System (on some models): Used for actions like pressurizing and lifting the drive rollers.

| Core Equipment Advantages |

Extremely High Wood Utilization Rate: This is its biggest selling point. It turns small-diameter logs, branch wood, cores, and other "waste" into valuable products, directly increasing economic benefits.

Spindleless Design, High Veneer Yield: Automatically finds the natural center, especially suitable for irregularly shaped wood, effectively reducing debris and resulting in a much higher yield compared to traditional methods.

High Precision and Excellent Surface Quality: Advanced CNC systems ensure uniform veneer thickness (tolerance can be controlled within ±0.05mm) and a smooth, high-quality surface, suitable directly for core sheets, back veneers, or construction formwork.

High Efficiency and Automation: Compact structure and short cycle times (from loading to finishing peeling takes only tens of seconds). Operable by one person, reducing labor intensity and increasing production efficiency.

Easy Operation and Maintenance: PLC control with parametric settings lowers the skill requirement for operators. The mechanical structure is relatively simple, facilitating maintenance.

High Return on Investment (ROI): The initial investment is lower compared to large peeling machines. However, because it transforms low-value raw materials into high-value products, the payback period is short.

Plywood/Engineered Wood Panel Industry: Specifically for producing core sheets and back veneers for plywood.

Blockboard Production: The peeled veneer can be used for overlays or filling.

Initial processing for small wood products like disposable chopsticks, popsicle sticks.

Production of packing case boards and construction formwork.

Biomass Energy Industry: Using the remaining smaller wood pieces from peeling directly for producing wood chips or biomass pellets.

Summary: The Efficient Peeling Machine for Small-Diameter Logs is a high-efficiency, precision equipment focused on enhancing resource utilization and processing low-value wood. Through its unique spindleless double-roller drive working principle, it successfully solves the industry challenge of processing small-diameter logs, making it a powerful tool for wood processing enterprises to achieve energy saving, consumption reduction, and profit increase.

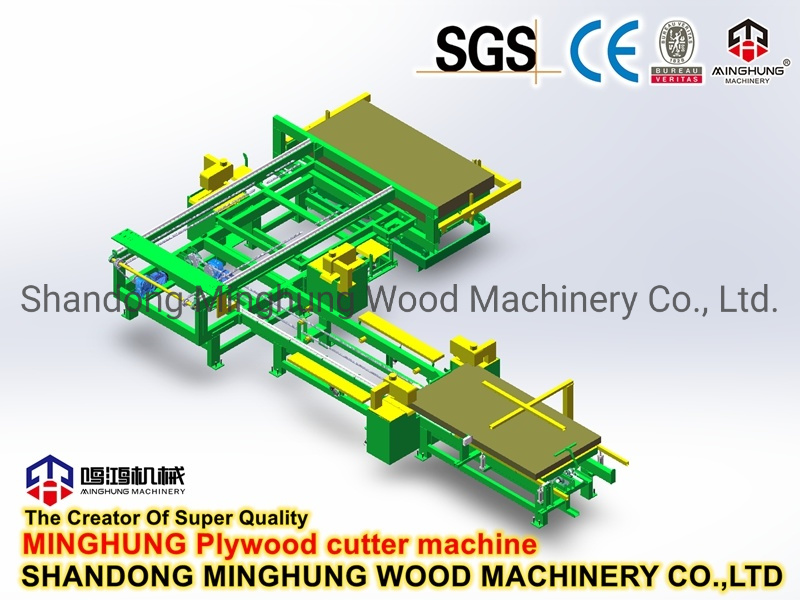

We are Shandong MINGHUNG Wood Based Panel Machinery Co.,Ltd China factory and manufacturer of full sets of Plywood machinery and Veneer machinery. With many years production experience, advanced production technology,experienced workers and professional engineers, we can offer you the suitable, good and strong machinery for you.