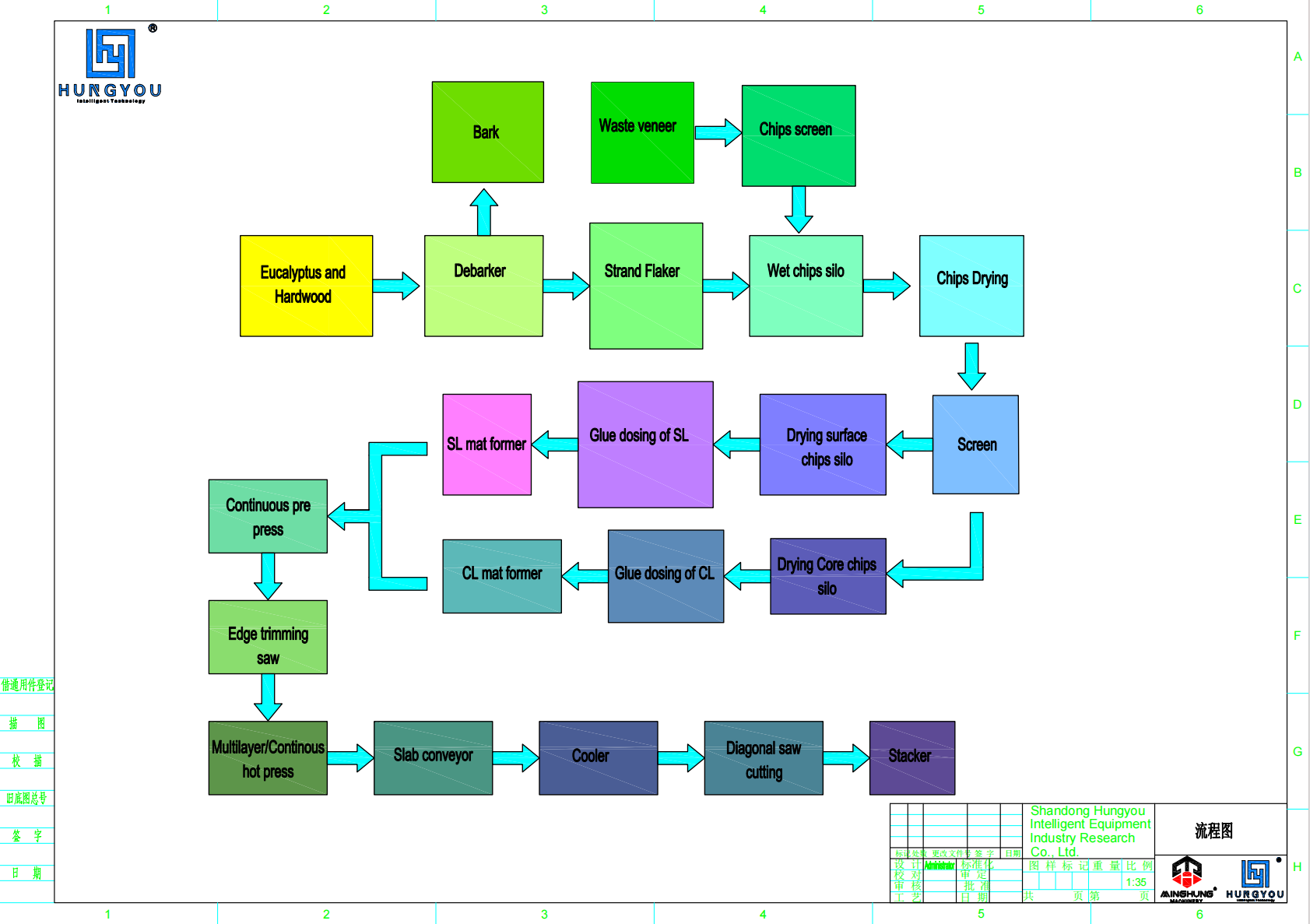

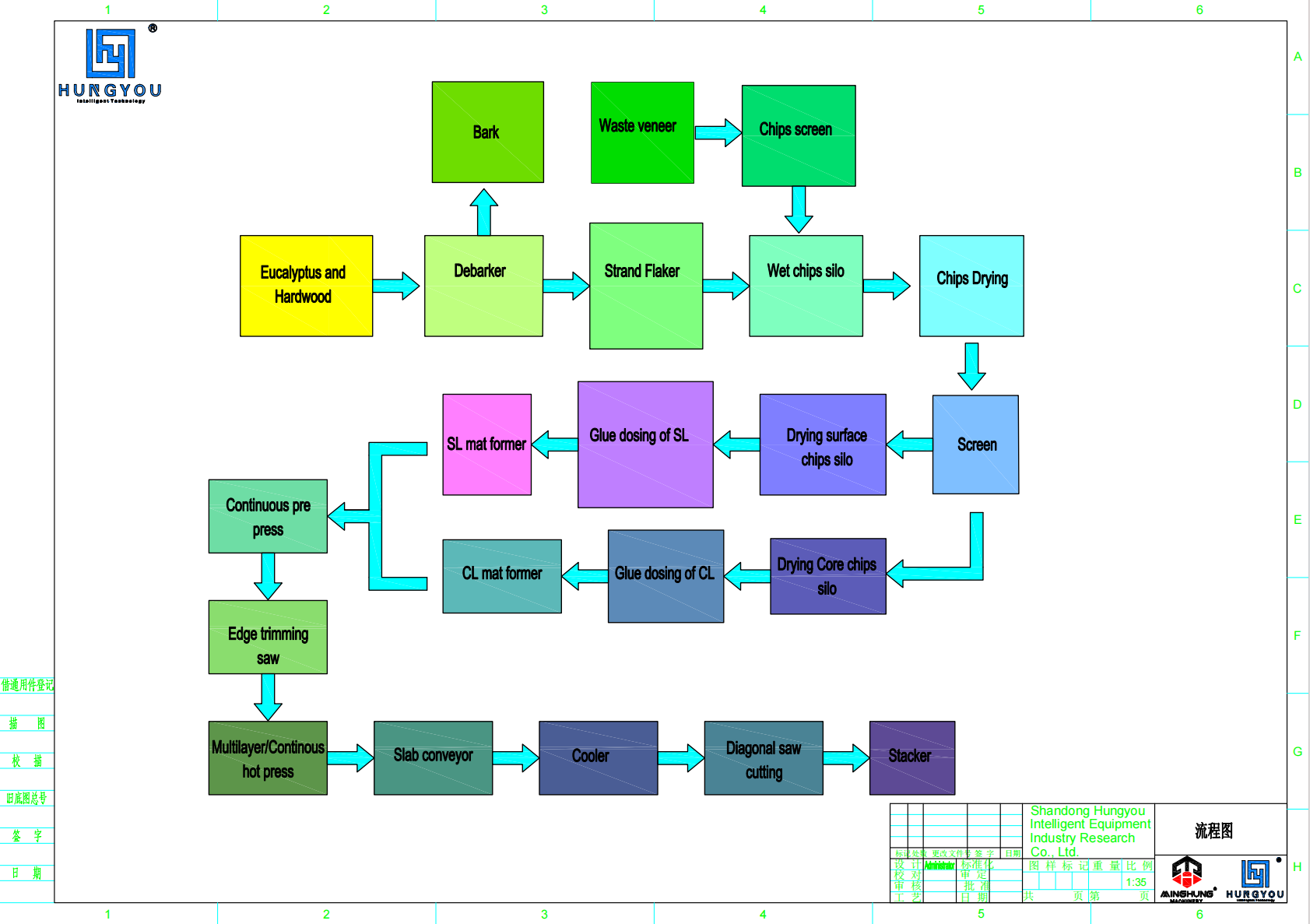

1.Working principle and process flow

(1) Directed paving and pre-pressing

Directed paving:

OSB wood chips are divided into surface layer (longitudinally arranged) and core layer (transversely arranged), and are oriented by a special paving machine (such as a mechanical directional head or airflow paving system). The length of the surface layer wood chips is usually 50-100mm, and the core layer wood chips are shorter (20-50mm).

Pre-pressing and shaping:

The paved slab enters the pre-pressing machine (pressure 0.5-1.5MPa), and the air is removed and the direction of the wood chips is initially fixed by mechanical roller pressing or high-frequency pre-pressing to prevent the structure from loosening during the subsequent hot pressing process.

(2) Continuous hot pressing stage

High pressure zone (initial curing):

Temperature 210–230℃, pressure 3.0–5.0MPa, quickly close the slab and activate the adhesive (usually phenolic resin or MDI adhesive), and the surface wood shavings directional structure is initially cured.

Medium pressure zone (plasticization balance):

Temperature 200–220℃, pressure 2.0–3.5MPa, maintain full penetration of the core layer adhesive, and balance the curing rate of the inner and outer layers.

Low pressure zone (setting and stress release):

Temperature 180–200℃, pressure 1.0–2.0MPa, control the final thickness and release internal stress to avoid board warping.

(3) Cooling and post-processing

Cooling section:

The pressed sheet is cooled to below 50°C by a circulating water cooling system to stabilize the sheet size.

Cutting and sanding:

The sheet is cut into standard sheets using a high-speed sawing system, and the surface flatness is adjusted using a sander.

2. Core Structure and Composition

2.1 Hot press plate system: Composed of multiple heating plates, the interior is heated by heat transfer oil or steam to provide uniform temperature.

2.2 Steel belt system: Two circulating steel belts (upper and lower) hold the slabs and run continuously to ensure uniform pressure transmission.

2.3 Hydraulic system: Pressure is applied through hydraulic cylinders, and the pressing force in different areas can be adjusted in sections.

2.4 Control system: PLC or computer control, real-time monitoring of parameters such as temperature, pressure and speed.

2.5 Auxiliary equipment: includes paving machines, pre-pressing machines, cooling sections, sawing systems, etc.

paving machine for OSB

pre press machine

cooling machine

3. Key process parameters

Parameters | Typical range | Function |

Surface shavings moisture content | 8–10% | Prevent the surface from being too brittle and improve bonding strength |

Core shavings moisture content | 4–6% | Reduce steam emission and avoid bubbling and stratification |

Hot pressing temperature | 220–230℃ in high pressure area, 180–190℃ in low pressure area | Layered curing and balancing internal stress |

Unit pressure | 4.0–5.0MPa in high pressure area, 1.0–1.5MPa in low pressure area | Oriented structural shaping to prevent shavings displacement |

Hot pressing time | 3–5s/mm (thickness) | Ensure that the adhesive is fully cured |

4. Application scenarios

Building structural materials: wall, roof, floor bearing layer (replacing traditional plywood).

Packaging and logistics: heavy pallets, container bottom plates.

Furniture manufacturing: customized furniture substrates, especially outdoor furniture (strong weather resistance).

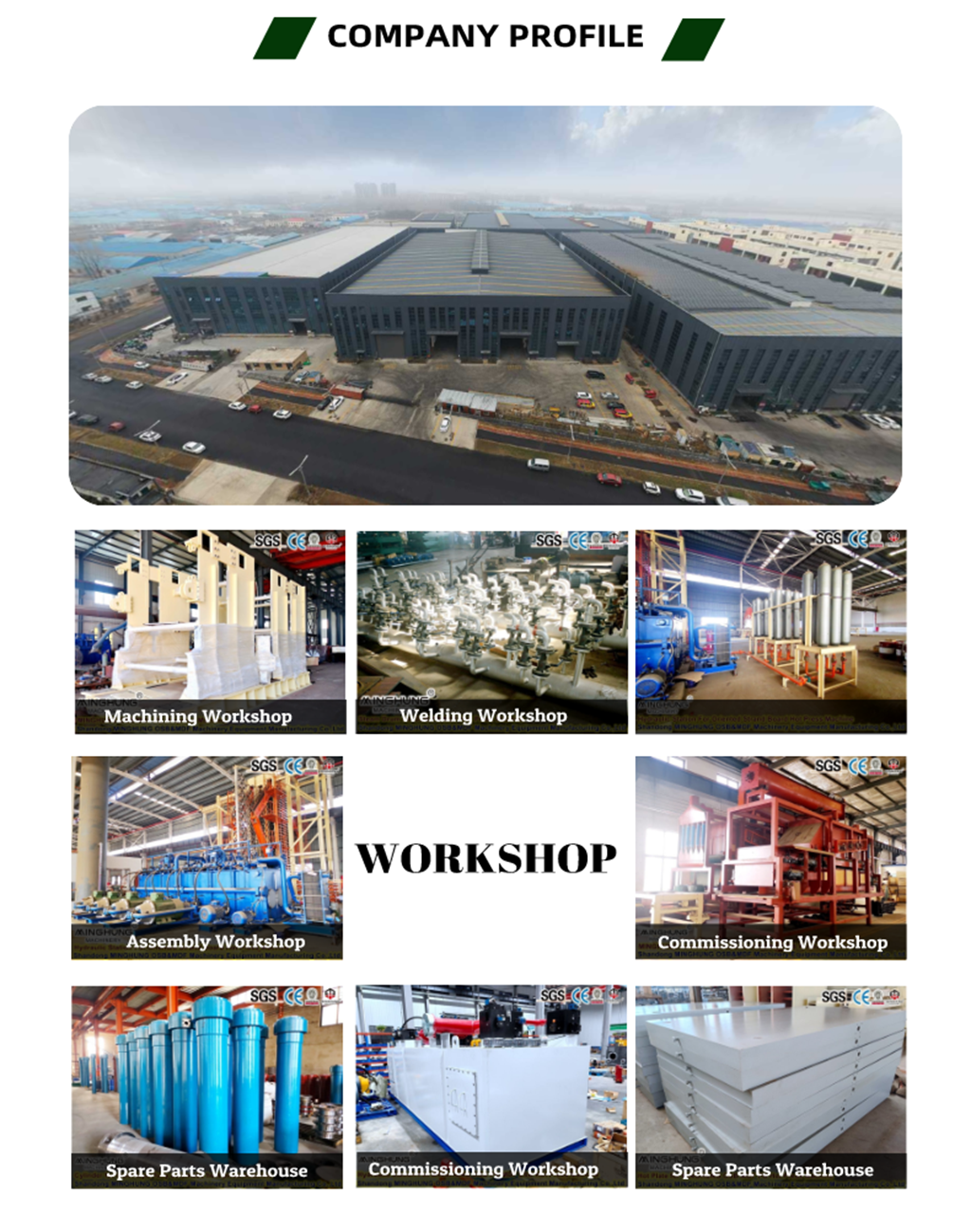

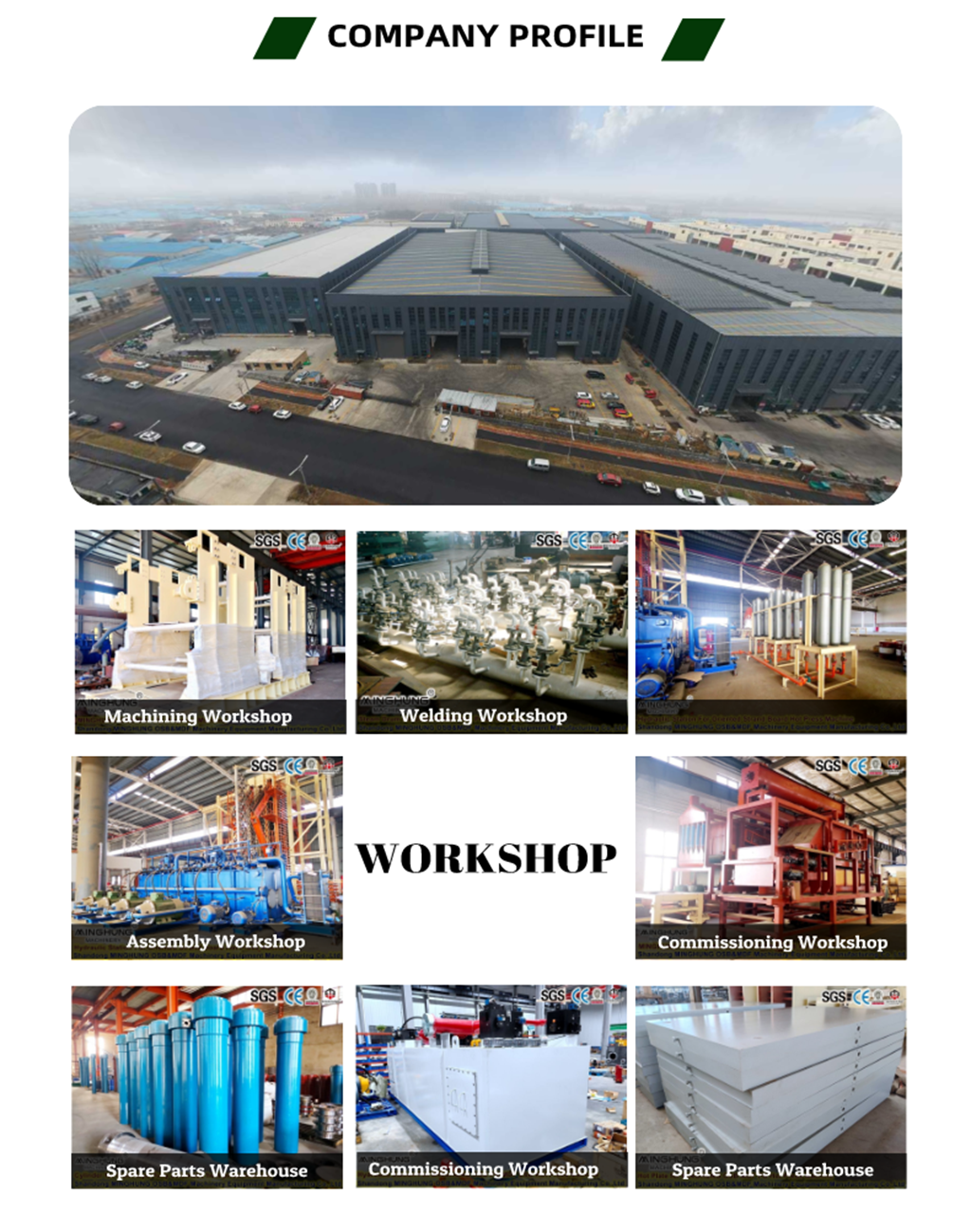

Shandong MingHung OSB&MDF Machinery Equipment is a China professional factory who specilize in manufacturering and offering Wood based panel machine, including OSB making machine, MDF making machine, and Chipboard /PB making machine.

Our factory with the advanced processing lathes, Mature production technology, and Professional engineers and technicians, and independent ability of reasearch and development, and quickly service, ensure that we have the ability to offer you the suitable and good woodworking machinery as different conditions and requires.

Claim Your Free OSB Line Layout! Get end-to-end plant design from strand preparation to sanding. Receive 3D factory plan within 30 days.

Whatsapp: +8618769900191 +8615589105786 +8618954906501

Email: osbmdfmachinery@gmail.com