| 1. Raw Material Preparation Section |

Drum Chipper

Working Principle: Wood (logs, small-diameter wood, board waste) is fed into a rotating drum with knives to be cut into uniform process chips.

Key Parameters: Disc diameter ≥2000mm, Capacity ≥100 BDMT/h, Chip length 20-30mm.

Flaker & Crusher

Working Principle: Flakers process chips into thinner flakes; Crushers break down oversized flakes.

Key Parameters: Flake thickness 0.2-0.5mm, Width 5-20mm.

Screening Machine

Working Principle: Uses multi-layer vibrating screens to grade flakes by size (fine face layer flakes, coarse core layer flakes), with oversize material returned for crushing.

Key Parameters: Typically 3-4 screen layers.

wood chipper

vibrating screen

| 2. Drying, Blending, and Fire Treatment Section |

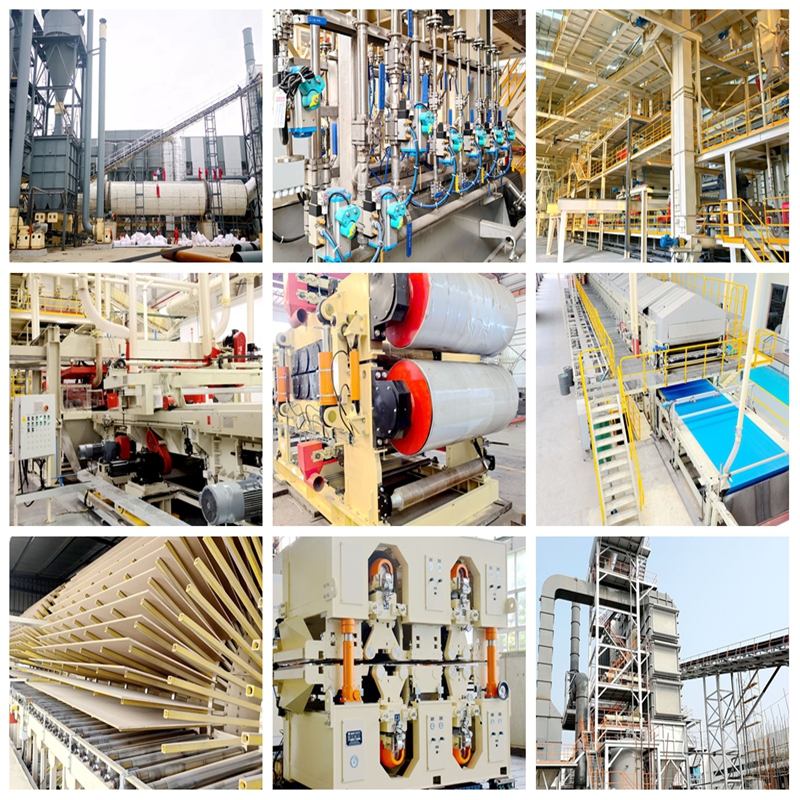

Rotary Drum Dryer

Working Principle: Hot air flows through a rotating drum, contacting wet flakes to reduce moisture content from ~40% to 2-4%.

Key Parameters: Evaporation capacity ≥10000 kg/h, Inlet temp ~400°C, Outlet temp ~100°C.

Ring Blender

Working Principle: Dried flakes are mixed uniformly with atomized resin and additives in a high-speed annular channel.

Key Parameters: Capacity ≥8000kg/h, Blending uniformity ≥95%.

Flame Retardant Dosing System

Working Principle: Core of fire-retardant production. High-precision pumps and nozzles accurately add liquid or powder retardants to the flakes at a set ratio (Usually, the gel mixing process is carried out simultaneously or in stages.).

Key Parameters: Addition rate 5%-15% (of oven-dry wood weight), Dosing accuracy ±0.5%.

dryer system

glue mixer

| 3. Forming and Pressing Section |

Mechanical Former

Working Principle: Spreads resinated and retarded flakes via scattering rolls and metering conveyors to form a uniform mat with a "fine-coarse-fine" three-layer structure.

Key Parameters: Forming width ≥8 ft (2440mm), Forming accuracy deviation ±1.5%.

Continuous Flat Press

Working Principle: The formed mat continuously enters between high-temperature (200-220°C), high-pressure (30-40 bar) steel belts where the resin and retardant cure rapidly under heat and pressure, forming a solid board. Key to achieving the high 600m³/day output.

Key Parameters: Press length ≥30m, Opening height 100mm, Platens temperature control accuracy ±2°C.

forming machine

continuous hot press

| 4. Finishing and Sanding Section |

Cooling Star (Rotary Cooler)

Working Principle: Cools the hot boards (~100°C) exiting the press evenly to room temperature, releasing internal stresses and stabilizing board properties.

Key Parameters: Cooling time ≥25 minutes.

Cross-Cut & Rip Saws

Working Principle: Cuts the continuous board into required large-format panels (e.g., 1220x2440mm).

Multi-Head Wide Belt Sander

Working Principle: Sands the boards to precise thickness and a smooth surface through multiple sanding heads (coarse & fine), removing the pre-cured layer.

Key Parameters: Sanding width ≥2650mm, Sanding amount 0.5-1.0mm, Thickness accuracy ±0.1mm.

Rotary Cooler

edge trimming and cutting

sander

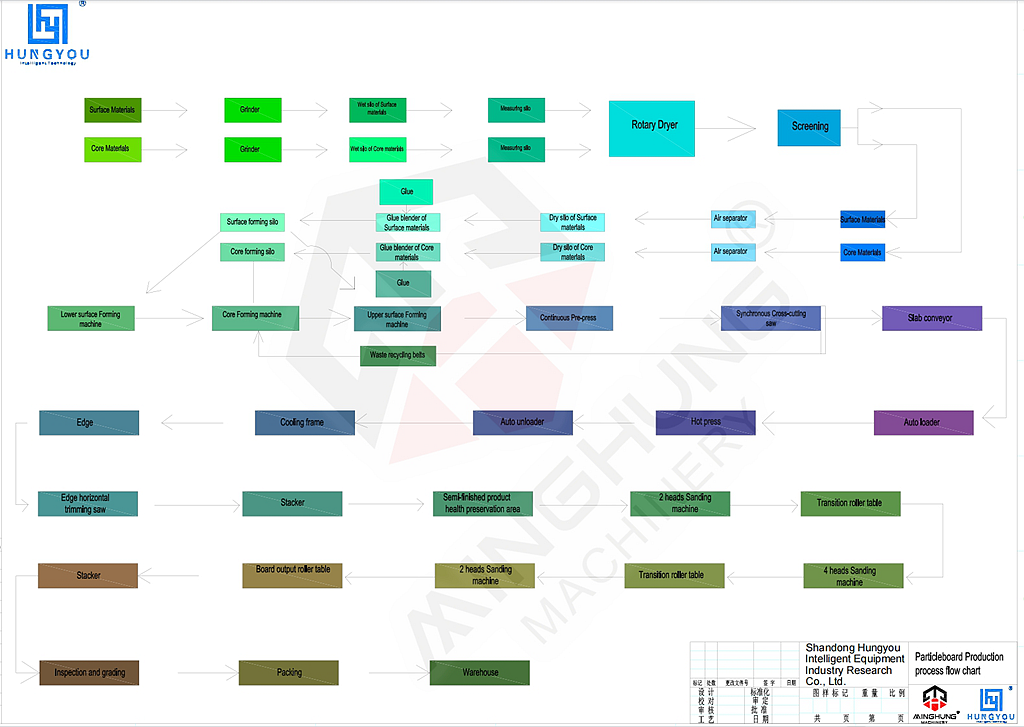

Production Process of Fire-Retardant Particleboard

The entire process can be divided into six main sections: Raw Material Preparation, Flake Preparation, Drying & Classification, Forming, Finishing, and Auxiliary Systems. The core of the process lies in uniformly and stably adding the flame retardant to the flakes and successfully curing it.

| Section 1: Raw Material Preparation |

1. Raw Material Receiving & Storage

Content: Receive wood raw materials, such as small-diameter logs, branch wood, wood processing residues (e.g., board edges, planer shavings). Materials are stored in designated areas in the yard.

Fire-Related Note: While not directly related to fire retardancy, the purity of the raw material (free of metal, sand, soil) affects subsequent processing quality and the final board's uniformity, indirectly influencing the stability of fire performance.

2. Chipping & Washing

Content: Raw materials are cut into uniform process chips using a drum chipper. The chips are then washed (with water or air) to remove sand, metal, and other impurities.

Purpose: To provide clean raw material for producing high-quality flakes. A clean surface promotes the uniform adhesion of resin and flame retardant in subsequent steps.

| Section 2: Flake Preparation |

3. Flaking

Content: The washed chips are fed into a flaker, where they are shaved into thin flakes by high-speed rotating blades.

Parameter Control: The thickness (0.2-0.5mm), length, and width of the flakes are strictly controlled. Flake size directly affects the board's mechanical strength and surface quality.

4. Screening & Grinding

Content: Flakes are classified by multi-deck vibrating screens into face-layer fines, core-layer coarse flakes, and oversized rejects. Oversized flakes are sent to a crusher for grinding and then re-screened.

Purpose: To enable the three-layer "fine-coarse-fine" mat structure, ensuring a smooth surface and high internal bond strength.

| Section 3: Drying, Blending & Fire Treatment |

This is the most critical section for imparting fire-retardant properties.

5. Drying

Content: The screened wet flakes (approx. 40%-60% moisture content) are dried in a rotary drum dryer using hot air to achieve a moisture content of 3%-4% (oven-dry basis).

Purpose: To prepare the flakes for blending. Excessive moisture would dilute the resin and flame retardant, leading to poor curing.

6. Blending with Resin & Flame Retardant

Content: Dried flakes enter a large ring blender. Here, resin (typically modified urea-formaldehyde or MDI) and flame retardant are atomized through high-pressure nozzles and uniformly sprayed onto the flakes.

Core Fire Retardancy Process:

Retardant Types: Commonly used include phosphorus-nitrogen intumescent flame retardants, inorganic retardants .

Addition Methods:

Primary Method (Simultaneous Addition): Resin and retardant are added simultaneously in the same blender. This is efficient and ensures good uniformity.

Sequential Addition: The retardant is added and mixed first, followed by the resin, ensuring more thorough penetration.

Dosage: Retardant dosage is typically 5%-15% of the oven-dry weight of the flakes, depending on the target fire rating.

Purpose: To ensure each flake is uniformly coated with resin and retardant. Uniformity is the most critical factor determining whether the fire performance meets standards consistently.

This line uses continuous pressing technology, integrating drying, gluing, flame retardant addition, forming, hot pressing, and cutting processes. It specializes in producing 12mm thick fire-retardant particleboard, complying with fire-resistant particleboard technical standards . The boards exhibit high fire resistance, low formaldehyde emission (E1 Level), and stable physical-mechanical properties.

This line uses continuous pressing technology, integrating drying, gluing, flame retardant addition, forming, hot pressing, and cutting processes. It specializes in producing 12mm thick fire-retardant particleboard, complying with fire-resistant particleboard technical standards . The boards exhibit high fire resistance, low formaldehyde emission (E1 Level), and stable physical-mechanical properties.