3. Log Transporter

The Function:

Transport log, one connect with wood debarker, another connect veneer peeling machine.

The Advantages:

This is the upgrade one, powerful to convey log, the chain will be fine. |

Specification:

Power: 4.4kw

Weight: 2t/pcs

Size: 3000*1800*1500mm |

4. Vacuum Veneer Stacker

The Function:

Automatic sorting wood veneer, save 2 workers, connect with veneer peeling machine.

The Structure:

Machine frame, lift table, convey belt, fan, electric box

The Advantages:

|

Specification:

4feet

Lifting mode: hydraulic lift

Veneer size: 1270*500-1270mm

Thickness:<3.6mm

Power: 18.55kw

Weight: 2.5t

Size: 6500*2000*2750mm |

5. Magnetic Knife Grinder

The Function:

Grinding knife, make it become sharp again.

The Advantages:

Knife is consumable, after using a while, knife edge will become blunt, if you have this grinding machine, will be conveniently and fast make knife become sharp again. Knife is also very important for peeling good quality wood veneer. |

Specification:

4feet magnetic

Knife length: 1500mm

Table size: 1500*160(200)mm

Power: 4kw

Weight: 800kg

Size: 2800*1000*1000mm

Customize machine according to your needs. |

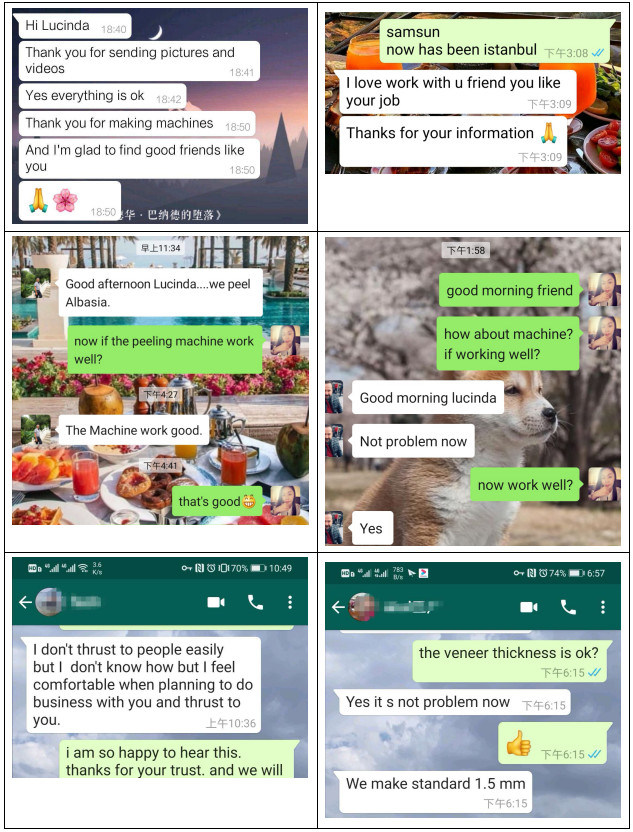

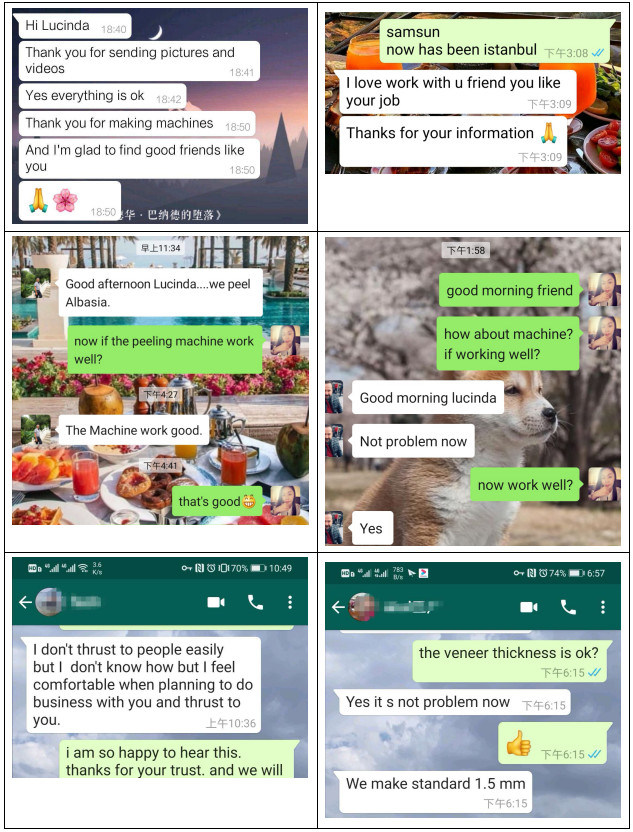

Machine in Clients Factory:

We often talk with our clients about machine working conditions, see if machine is well. If they meet some problems, we will help them solve it in time. The moment when you choose us, we have been your lifetime partners, anytime you need help, we will be there. Clients Comment:

We often talk with our clients about machine working conditions, see if machine is well. If they meet some problems, we will help them solve it in time. The moment when you choose us, we have been your lifetime partners, anytime you need help, we will be there. Clients Comment:

Delivery:

Delivery:  When machine finish production, we will share test video and pictures to you. When loading, we will send loading pictures to you. After ship leave, we will offer you container no and ship information, and prepare all documents for your custom clearance. China MINGHUNG factory offer plywood machine and veneer machine:

When machine finish production, we will share test video and pictures to you. When loading, we will send loading pictures to you. After ship leave, we will offer you container no and ship information, and prepare all documents for your custom clearance. China MINGHUNG factory offer plywood machine and veneer machine:

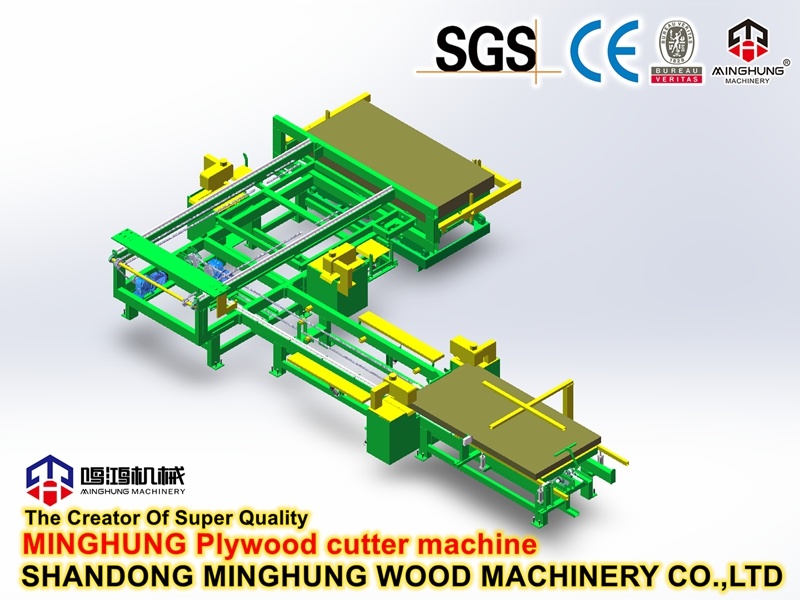

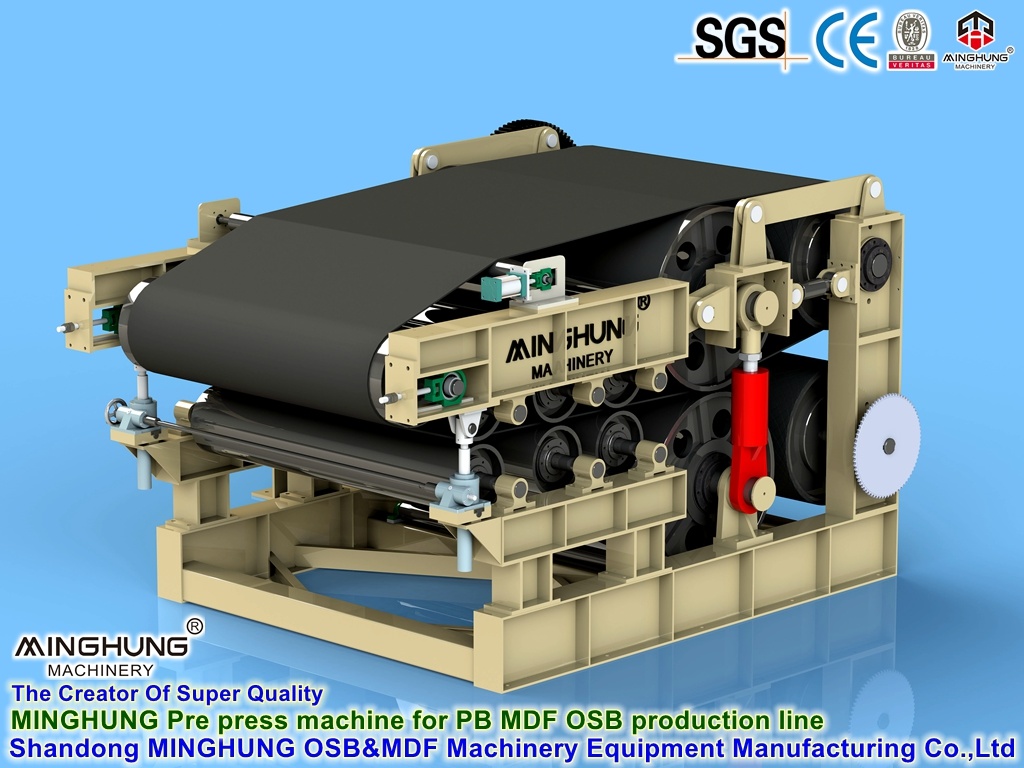

Shandong MINGHUNG Wood Machinery Co.,Ltd is one famous manufacturer of plywood machine in China, located in Linyi city.

Machine mainly includes: veneer peeling lines(wood debarker, veneer peeling machine, log conveyor, vacuum veneer stacker), veneer dryer(roller dryer, mesh dryer, press dryer), core composing machine, veneer glue machine, plywood cold press machine, hot press machine, film hot press machine, sanding and calibrating machine, lift table, steam and oil boiler.

Our company integrates design, research and development, production and sales, and works closely with China's advanced scientific research institutions. We have a strong research and development team, at present, our machinery has won a number of national patents.

Pay more attention to machine details, details determine success or failure, so we continuous improve and optimize machines’ performance, strictly control each production step, using advanced lathe and equipment processing machine, and through many times inspections, make sure our plywood veneer machine accurate and durable.

Scientific and technological innovation oriented, quality-based, service supremacy, we offer full complete range of plywood production solution and technology support for our customers. Yet our machines have been exported more than 30 countries and regions like Russia, Poland, Ukraine, Portugal, Bulgaria, Romania, Turkey, Egypt, Morocco, Indonesia, etc, and get good feedback.

Plywood Machine:  RFQ:

RFQ: | Production Time: |

| 1 month after receive your deposit. |

| Payment Terms: |

30% deposit, 70% before delivery.

100% Letter of Credit. |

| Warranty: |

| 2 years for main parts. |

| MOQ: |

| 1 set |

| Installation: |

| When machine reach your factory, our engineer can go to install |

| After-sales service: |

| Any problem that your worker can not solve, tell us, we will reply you at the first time, |

Contact us: whatsapp/telegram: +8618769900191 +8615589105786 +8615805493072

website: www.plywoodmachineline.com

email: minghungmachinery@gmail.com