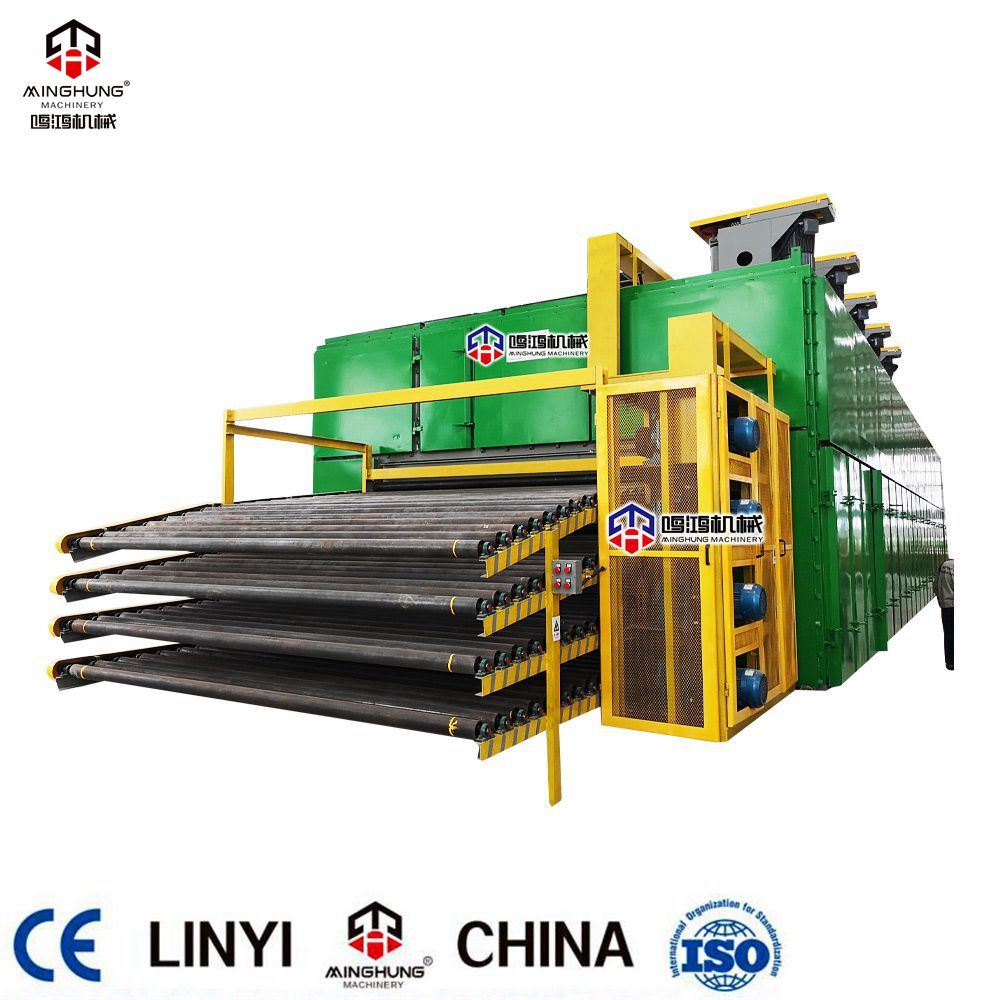

A modern automated plywood veneer drying machine is a complex system primarily composed of the following core components:

1. Main Structure System

Insulated Chamber: Typically made of high-quality color steel plates filled with high-performance insulation material (e.g., rock wool), it creates a sealed drying space, effectively preventing heat loss and improving thermal efficiency.

Steel Frame: Provides robust support for the entire equipment, ensuring stable operation under prolonged high-temperature and high-humidity conditions.

2. Heating System

Heat Source Unit: The core that generates drying heat, with options including steam boilers, thermal oil heaters, gas burners, or electric heaters, depending on customer conditions.

Heat Exchanger: Transfers energy from the heat source safely and efficiently to the drying medium – air.

3. Ventilation and Circulation System

Circulation Fans: Powerful fans are the driving force that ensures hot air is forced to circulate evenly within the drying chamber, guaranteeing uniform heating across the top, bottom, and sides of the veneers.

Air Ducts and Baffles: Scientifically designed to guide hot air through the veneer stacks at optimal velocity and direction, avoiding dead zones and enabling efficient heat transfer.

Air Inlet/Exhaust Dampers: Used to exhaust moist, hot air and supply fresh air, thereby precisely controlling the humidity inside the drying chamber.

4. Material Handling System

Conveying Mechanism: Usually a multi-layer mesh belt or chain-track structure that smoothly carries the veneers into, through, and out of the dryer for continuous operation.

Speed Control Device: By adjusting the conveyor speed, the residence time of the veneers inside the dryer can be precisely controlled to accommodate different initial and final moisture content requirements.

5. Automated Control System (The Core of Automation)

PLC (Programmable Logic Controller): The brain of the equipment. It receives signals from various sensors and commands all components to work in coordination according to pre-set programs.

HMI (Human-Machine Interface) Touchscreen: Allows operators to set drying process parameters (e.g., temperature, humidity, time) and monitor equipment status and drying curves in real-time.

Sensors: Including temperature and humidity sensors, they continuously monitor the internal conditions of the dryer and feed the data back to the PLC.

Actuators: Such as motorized control valves and frequency inverters, they receive commands from the PLC to precisely control valve openings, fan speeds, etc.

6. Safety and Protection System

Over-temperature Protection: Automatically cuts off the heat source in case of abnormal temperature rise to prevent equipment damage and fire.

Motor Overload Protection: Prevents fans, conveyor motors, etc., from burning out due to overload.

Alarm System: Alerts operators via audible and visual signals when any abnormality occurs in the equipment.