Product Description

The Four-Roller Precision Glue Spreader Plywood Production Line is a high-performance production system developed by Shandong Minghong Woodworking Machinery, based on core glue application technology. Centered around an industry-leading Four-Roller Precision Glue Spreader, this line achieves efficient operation across the entire process – from veneer feeding and precision gluing to automatic layup and hot pressing – through optimized automated workflow integration. It is specifically designed to address core pain points in plywood production, such as "uneven glue application, high glue consumption, and poor bonding," making it the ideal choice for businesses aiming to enhance product quality, reduce production costs, and strengthen market competitiveness.

The Design Essence: Precision and Efficiency

The design essence of this production line is to maximize the core value of "precision glue application" and seamlessly integrate it with upstream and downstream processes.

Core Objective: To fundamentally ensure the interlayer bonding strength and flatness of the finished plywood by achieving ultimate uniformity in glue application, while significantly reducing adhesive consumption.

System Philosophy: Modular, Intelligent, Low-Maintenance. The production line is optimally arranged around the four-roller glue spreader, ensuring smooth material flow and maximum efficiency.

Applicable Scenarios: Suitable for medium-sized manufacturers with an annual output of 10,000 to 30,000 cubic meters, particularly ideal for producing high-quality furniture boards, decorative panels, and E0/E1 grade eco-friendly boards.

Plywood Production Process

Plywood production is a process of bonding thin wood veneers peeled from logs into a solid panel using adhesives under pressure. The main production steps are as follows:

1. Log Processing & Peeling: Logs are debarked, softened by steaming/cooking, and then mounted on a lathe. They are rotated against a blade, peeling a continuous ribbon of veneer.

2. Veneer Drying & Preparation: The wet veneer from the lathe is fed into a dryer to reduce its moisture content to a suitable range (typically 8%-12%). It is then clipped, graded, and spliced in preparation for layup.

3. Gluing: Prepared adhesive (e.g., Urea-Formaldehyde) is applied evenly to both surfaces of the core veneers. This is a critical step determining bonding quality.

4. Layup (Assembling): The glued core veneers and unglued face/back veneers are assembled together, with the grain direction of adjacent layers perpendicular to each other, forming a "mat".

5. Pre-pressing: The mat is cold-pressed to achieve initial bonding, making it easier to handle and reducing deformation during hot pressing.

6. Hot Pressing: The mat is loaded into a hot press. Under high temperature and pressure, the adhesive cures completely in a short time, permanently bonding the multiple veneer layers into a solid panel.

7. Post-processing: The pressed panels undergo cooling, edge trimming, and sanding to become finished plywood with accurate dimensions and a smooth surface.

Major Production Equipment in the Line

This production line integrates modern automated equipment required for the above processes, ensuring efficient and high-quality production.

1. Veneer Dryer

Used to rapidly and uniformly dry the wet veneer after peeling to the appropriate moisture content. It is the fundamental equipment ensuring subsequent bonding quality and final panel flatness.

2. Four-Roller Precision Glue Spreader - Key Equipment

This is the core equipment of the production line, responsible for applying adhesive precisely and evenly onto the veneer surface.

Detailed Introduction:

Working Principle: It operates via the synchronized action of four precision-matched rollers (Pick-Up Roller, Metering Roller, Application Roller, and Reverse Compensation Roller). The adhesive is transferred and metered through these rollers, forming an ultra-thin, uniform film which is finally transferred onto the veneer.

Core Advantages:

Excellent Application Uniformity: Eliminates streaks or bare spots common in traditional spreaders, laying the foundation for producing high-strength plywood.

Precise Glue Control: Achieves significant glue savings (typically 10%-15% compared to two-roller machines), directly reducing production costs.

High Adaptability: Easy to adjust for different wood species, veneer thicknesses, and adhesive viscosities.

3. Automatic Layup Line

Automatically assembles and aligns glued and unglued veneers to form a mat. It fully replaces manual labor, offering high efficiency, low error, and ensuring a symmetrical mat structure.

4. Pre-press

Applies pressure to the assembled mat to achieve initial bonding, increasing its strength for easier loading into the hot press while removing internal air.

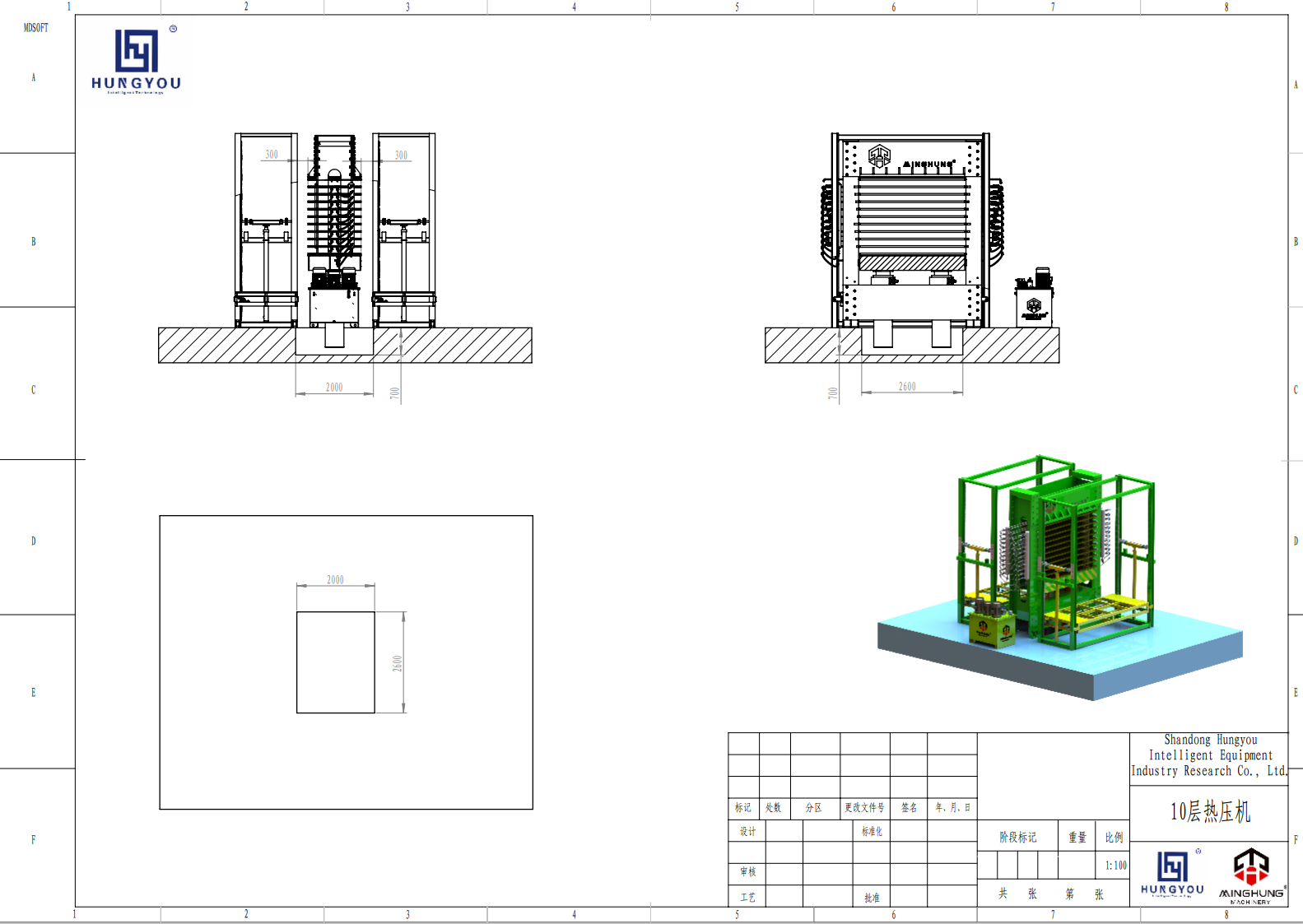

5. Hot Press

The "heart" of the production line. By providing a precise high-temperature and high-pressure environment, it rapidly cures the adhesive in the mat, achieving permanent bonding. Its performance directly determines the final mechanical strength and quality of the plywood.

6. Post-processing Equipment Group

Cooling & Turning System: Allows the high-temperature panels after hot pressing to cool uniformly, preventing deformation.

Cross-Cut & Trim Saws: Automatically cut the rough edges of the panels to standard dimensions.

Double-Side Calibrating Sander: Precisely sands the top and bottom surfaces of the panel to ensure consistent thickness and a smooth surface, meeting the final product standard.

7. Central Control System (PLC)

Acts as the brain of the production line, uniformly controlling and coordinating the operation of all equipment, enabling parameter setting, process monitoring, fault diagnosis, and data logging.

Core Advantages & Value Creation 1. Enhance Product Quality, Build Brand Reputation:

Uniform glue layers result in higher bonding strength, creating stable panel structures resistant to delamination and offering excellent physical properties.

Exceptional panel flatness provides a perfect substrate for subsequent deep processing like laminating or painting, enhancing product marketability.

2. Significantly Reduce Overall Production Costs:

Direct Glue Savings: 10%-15% savings in adhesive translate into substantial cost reduction over long-term production.

Reduce Rejection Rate: Defects like delamination and blistering caused by gluing issues are drastically reduced, improving overall output efficiency.

Lower Labor Costs: Automated line operation reduces dependence on skilled gluing operators, lowering management and labor costs.

3. Increase Production Stability & Efficiency:

Stable equipment operation with low failure rates ensures smooth execution of production schedules.

Efficient integration with the automatic layup system avoids production bottlenecks, resulting in high overall output efficiency.

4. Support Environmental Protection & Green Manufacturing:

Saving glue means reducing the overall usage and emission of chemicals like formaldehyde, making it easier to produce panels that meet international environmental standards like E0/E1, helping customers access high-end markets.

Technical Parameter Overview Parameter Item | Specification Description |

Core Gluing Equipment | Four-Roller Precision Glue Spreader |

Applicable Veneer Width | 1300mm, 1500mm (Customizable) |

Glue Application Control Range | Precisely adjustable, typically covering 100 - 400 g/m虏 (Depends on adhesive type) |

Production Line Automation Level | Fully automatic from gluing to layup |

Recommended Annual Capacity | 10,000 - 30,000 cubic meters |

Total Installed Power | Approx. 200 - 350 kW (Depends on specific configuration) |

Shandong Minghong Woodworking Machinery's Four-Roller Precision Glue Spreader Plywood Production Line is more than just a set of equipment; it embodies an engineering philosophy of "precision manufacturing." We are well aware that outstanding quality stems from the meticulous control of every core process.Choosing us means gaining a comprehensive partner who deeply understands plywood manufacturing processes and can provide all-around support from equipment selection and process debugging to long-term technical support. Let us help you build a lasting reputation in the global market with stable and reliable product quality.