|

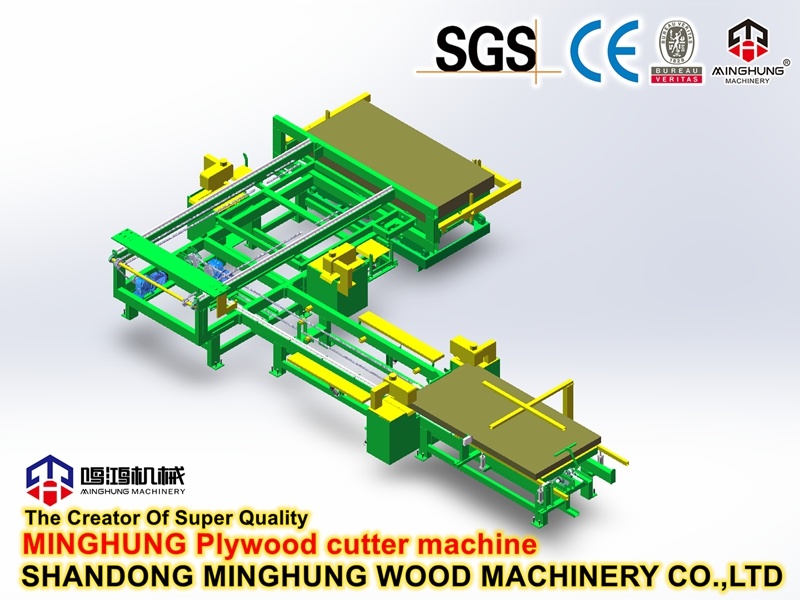

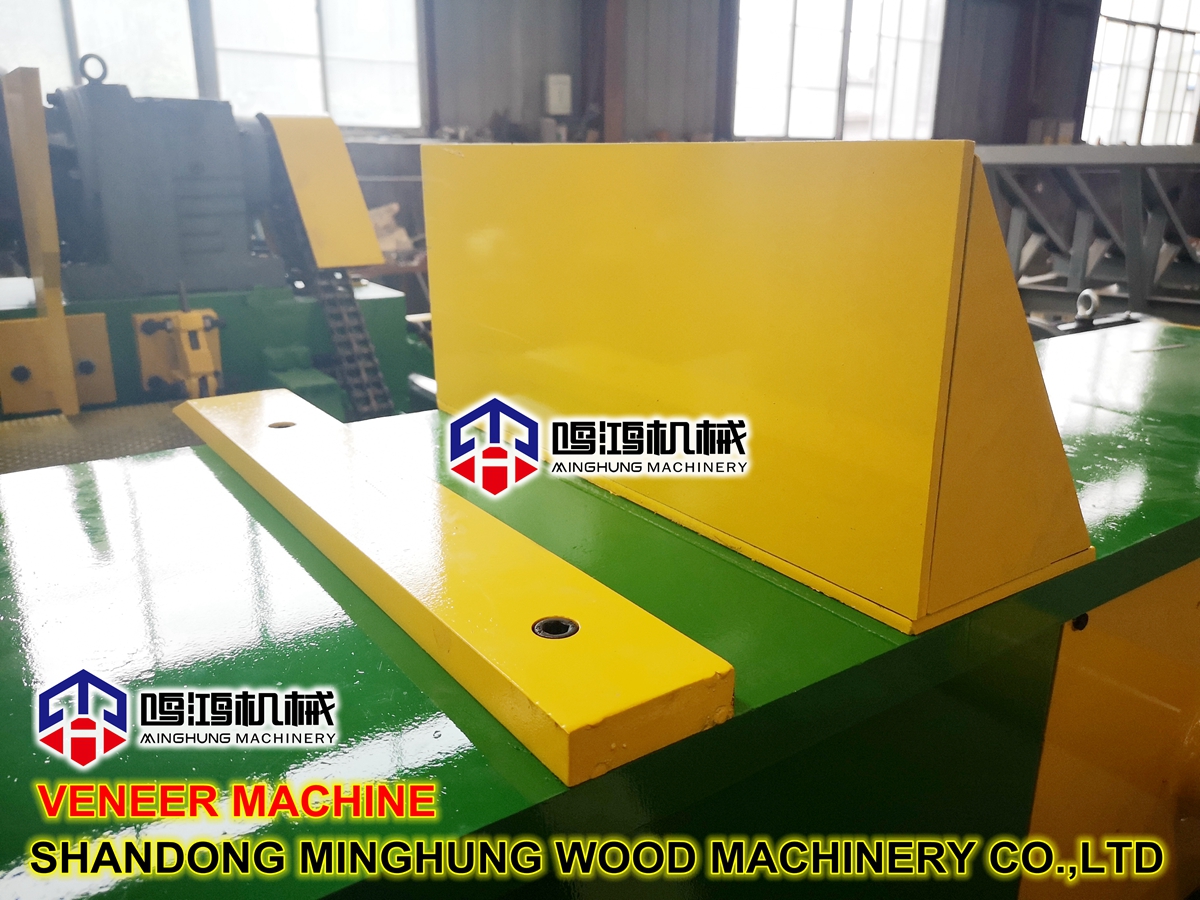

Product Description

A veneer peeling machine is a core piece of equipment in a plywood production line. It is used to clamp and uniformly rotate a softened log (block) while a precisely fed peeling knife continuously cuts it into a veneer sheet of preset thickness. The "durable" aspect is a core design goal, meaning the equipment can maintain processing accuracy, stability, and a low failure rate over the long term under high-load, continuous production environments.

|

Working Principle

Chuck spindles clamp and drive the log to rotate. A peeling knife mounted on a precision knife carriage moves in a horizontal, linear feed motion. A precise mechanical or CNC system controls the speed ratio between rotation and feed, enabling constant linear speed peeling to ensure uniform veneer thickness.

|

Core Components

Frame: Made from thick cast steel or high-quality welded steel plates, stress-relieved. This is the foundation of machine stability.

Spindle Head & Chuck Spindles: High-power main motor, heavy-duty gearbox, and chuck spindles supported by heavy-duty bearings. Provide powerful rotational torque and clamping force.

Knife Carriage & Feed System: Includes the peeling knife, pressure bar, knife holder, and a precision ball screw or hydrostatic screw drive system. Determines veneer thickness accuracy and surface quality.

Drive System: Traditional mechanical stepless speed variation or modern servo/frequency conversion drives. Modern durable models often use full servo or hydrostatic drives for smoother operation.

Control System: Evolved from traditional relay logic control to current PLC + touchscreen interfaces. High-end models are equipped with CNC systems capable of storing and recalling process parameters for different wood species and specifications.

|

Core Manifestations

Durability is not a single metric but is integrated throughout the entire process of design, material selection, manufacturing, and usage.

1. Robust Structure, Resistant to Fatigue Deformation:

Heavy-Duty Frame: Uses high-strength materials, with a structure optimized via Finite Element Analysis (FEA) to prevent deformation under long-term asymmetric cutting forces.

Reinforced Critical Components: Core transmission parts like chuck spindles, gears, and screws are made from alloy steel and undergo surface hardening treatments (e.g., quenching, nitriding) for excellent wear resistance.

2. Precise and Reliable Transmission & Drive Systems:

Application of Hydrostatic Technology: High-end durable models employ hydrostatic bearing technology for the main spindle and feed screw. The spindle rotates on a high-pressure oil film, and the screw moves within an oil film, resulting in near-zero wear, extremely long precision life, and exceptionally smooth operation.

Servo Drives: The feed system uses high-response servo motors for direct drive, eliminating complex mechanical speed change mechanisms, reducing potential failure points, enabling more precise control, and offering faster dynamic response.

3. Design and Material Selection for Critical Wear Parts:

Peeling Knife & Pressure Bar: Made from special tool steel or fitted with carbide inserts for high hardness, wear resistance, and impact resistance. The material and profile design of the pressure bar are also crucial.

Chuck Points & Anti-Deflection Rolls: Chuck points (the spiked ends of the spindles) require high strength and wear resistance to ensure no slippage and no damage to the log core. The material and surface treatment of anti-deflection rolls must also be wear-resistant.

4. Advanced Control and Detection Systems:

Automatic Thickness Detection & Feedback: Online laser thickness gauges monitor veneer thickness in real-time, feeding signals back to the control system to automatically fine-tune the feed speed, compensating for knife wear or variations in wood hardness, ensuring long-term thickness tolerance (can reach ±0.05mm).

Intelligent Protection: Features overload protection, hydraulic system monitoring, temperature monitoring, etc., preventing the machine from operating under abnormal conditions and avoiding accidental damage.

5. Design for Maintainability:

Modular Design: Key components are easy to disassemble, replace, and maintain.

Centralized Lubrication System: Ensures all bearings and sliding surfaces receive regular, measured lubrication, reducing wear.

|

Main Type of Peeling Machine

1. Spindle-Type Peeling Machine: The traditional workhorse, suitable for large-diameter logs and high-quality veneer production. Durable spindle-type machines are evolving towards full CNC, servo/hydrostatic drive systems.

2. Spindleless Peeling Machine: More suitable for small-diameter logs, fast-growing timber, and re-processing of log cores. Their durability is reflected in the dual-servo or hydraulically driven pinch roller system, powerful torque output, and precise synchronous control.

|

Wide Applicability

This machine is not only suitable for fast-growing woods like eucalyptus and poplar but, thanks to its rugged construction, also handles the peeling of various hardwoods with ease. It serves as the core equipment for reliable production lines in plywood, blockboard, and LVL manufacturing.

We promise not just a machine, but sustained productivity and a secure investment.

|

Product Packaging

|

Comment & FAQ

Q:How long the production time?

A:If one set machine,3-4 months;If the full production line 6-8 months.

Q:How is your quality?

A:As an experienced manufacturer, the quality of our machines can be guaranteed and we have supplied our products to thousands of customers all over the world.

Q:Can you do OEM /ODM?

A:Yes, we can do OEM/ODM according to your technical requirements.

Q:What payment methods do you offer?

A:Usually T/T and LC. If you have other payment methods, we can also consider it.

|

Company Profile

We are Shandong MINGHUNG Wood Based Panel Machinery Co.,Ltd China factory and manufacturer of full sets of Plywood machinery and Veneer machinery. With many years production experience, advanced production technology,experienced workers and professional engineers, we can offer you the suitable, good and strong machinery for you.

The machinery we produce includes peeling machines, chipping machines, rotary cutting machines, drying machines, gluing mixers, laying machines, pre-pressing machines, hot pressing machines, cooling machines, longitudinal and transverse sawing machines, sanding machines, as well as auxiliary machinery such as automatic feeding and discharging systems and lifting platforms.

|

Customer group photos