The fully automated process is designed to transform raw logs into high-quality finished plywood with minimal manual intervention, utilizing automated equipment and a central control system. The entire process can be divided into eight core stages:

1. Raw Material Handling & Preparation

Process: Logs (e.g., Eucalyptus, Pine, Poplar) are automatically fed into the production line via conveyor chains or forklifts. They first pass through a Debarker to remove bark and impurities. Then, a Cross-Cut Saw precisely cuts them into required lengths, forming process blocks.

Automation: Automatic feeding, automatic length-cutting.

2. Block Softening Treatment

Process: The cut blocks are transferred to a Steaming Pool (or Tank) for hot water or steam treatment. This process softens the wood fibers, reducing hardness and preparing them for high-quality peeling.

Automation: Automatic temperature and time control.

3. Veneer Peeling & Drying

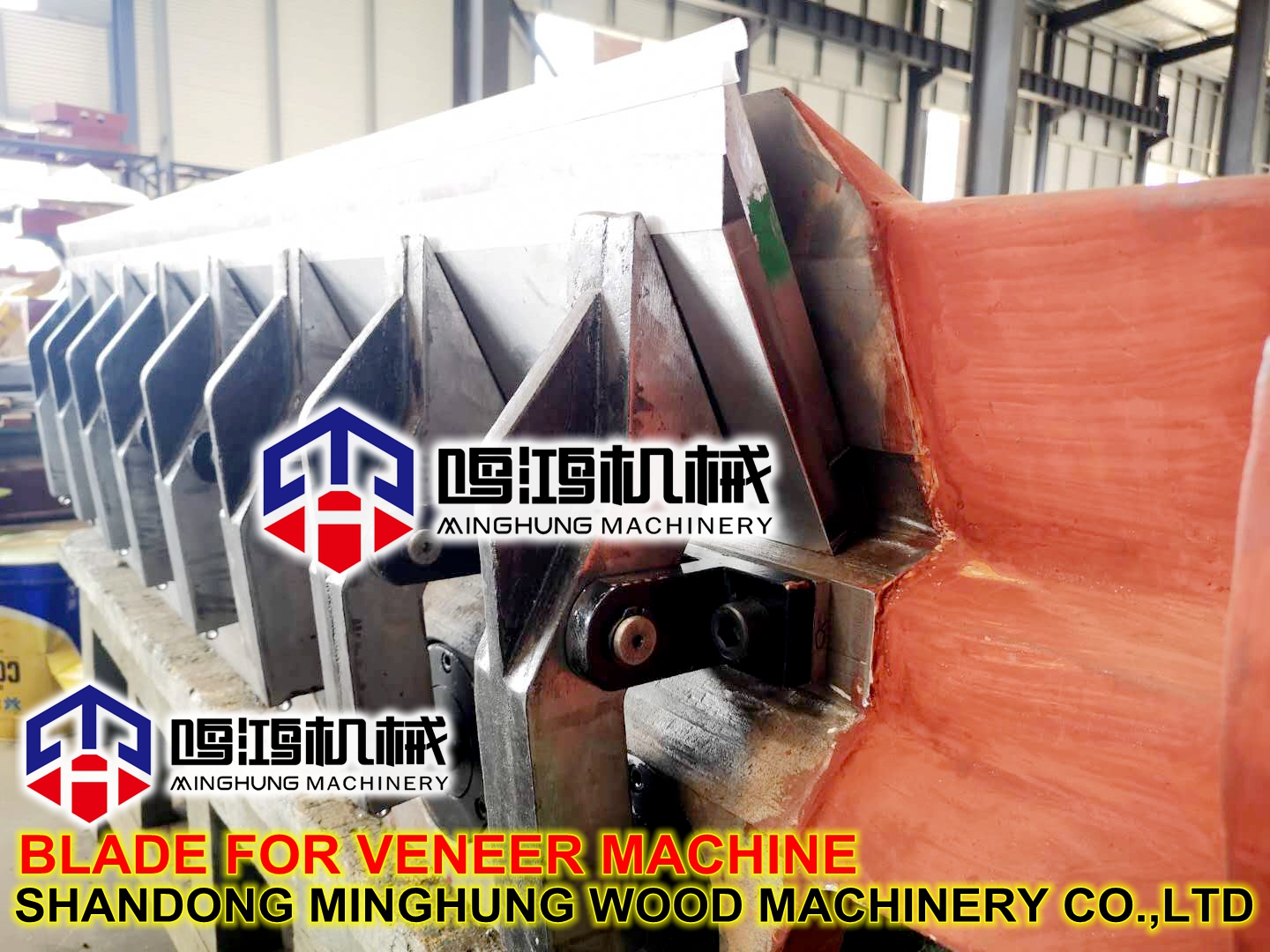

Process: Softened blocks are conveyed to the Peeling Lathe. The lathe peels the block like a pencil sharpener, producing a continuous ribbon of uniform-thickness veneer. This ribbon then enters a Veneer Dryer, where hot air rapidly reduces its moisture content to the required standard (typically 8%-12%) to prevent mold and ensure bond strength.

Automation: Automatic peeling, automatic feeding into the dryer, automatic temperature and speed control during drying.

4. Veneer Composing & Processing

Process: Dried veneer passes through a Veneer Clipper, where it is cut to set dimensions. Subsequently, a Veneer Sorting and Patching System automatically sorts the sheets based on size and defects, and automatically splices or patches defective areas, significantly improving wood utilization.

Automation: Automatic clipping, automatic sorting, automatic patching/splicing.

5. Automatic Gluing & Layup

Process: This is the core stage of "Full Automation." Qualified veneer sheets are fed into an Automatic Glue Spreader, which applies adhesive (e.g., Phenolic Resin) evenly onto their surfaces. Then, a Fully Automatic Layup Machine stacks the glued and unglued veneers precisely and rapidly into a mat according to preset layers and structure (e.g., face, core, back). This completely replaces the traditionally labor-intensive and error-prone manual layup.

Automation: Automatic, quantitative glue spreading; fully automatic, precise layup; automatic pre-pressing.

6. Hot Pressing

Process: The assembled mat is loaded into a Multi-Opening Hot Press by an Automatic Loader. Under precisely controlled high temperature (e.g., 180-200°C) and high pressure (e.g., 100-150 kg/cm²), the adhesive in the mat cures rapidly within a short time, bonding the multiple veneer layers firmly into a solid plywood panel.

Automation: Automatic loading and unloading; PLC-controlled temperature, pressure, and time.

7. Finishing & Processing

Process: The hot panels exiting the press first pass through a Cooling & Turning Stacker for temperature reduction and neat stacking to release internal stress. The panels then enter a Calibrating Sander for surface finishing, ensuring consistent thickness and a smooth, flat surface. Finally, Cross-Cut and Rip Saws trim the panel edges square to the final customer-required dimensions.

Automation: Automatic cooling and stacking, automatic calibrating sanding, automatic edge trimming.

8. Inspection & Packaging

Process: Finished panels undergo automatic (or sampling) inspection, followed by automatic packaging equipment for film wrapping, bundling, and labeling, before being stored in the warehouse.

Automation: Automatic packaging, labeling.