450kg/m³ Lightweight Particle Board Production Line

with 50000m³Annual

|

Required Main Machinery and Equipment

A 50, 000 m³ annual capacity lightweight particleboard production line is a compact and efficient system, with equipment designed and selected around the core concept of "creating a loose structure." The main equipment includes:

1. Raw Material Preparation Section

Chipper: Processes wood (e.g., fast-growing poplar, pine, recycled wood) into process-specific chips.

Flaker: Processes large chips or small wood pieces into large, flat flakes, ideal for producing high-quality surface layer material.

Crusher/Refiner: Re-crushes oversized flakes or material from the flaker to produce smaller particles for the core layer.

Screening System: Precisely grades particles by size. Surface material (fines) and core material (coarse particles) are stored and processed separately. This is key to achieving the "dense surface, loose core" structure.

wood chipping machine

vibrating screen

2. Drying, Blending, and Gluing Section

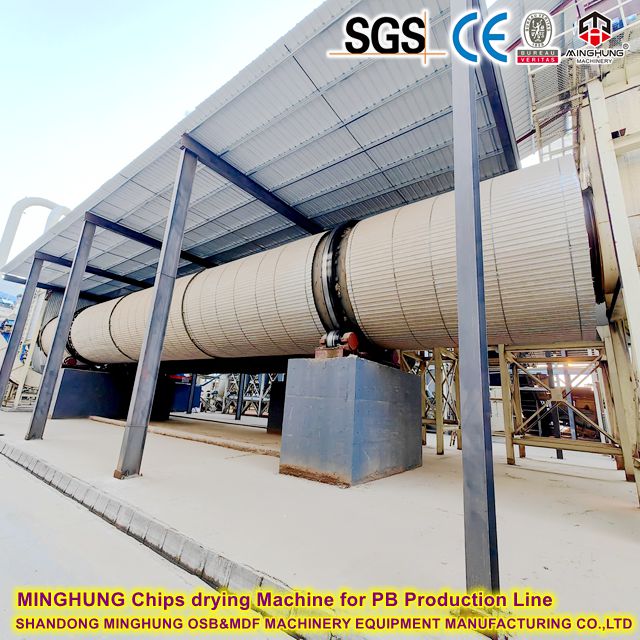

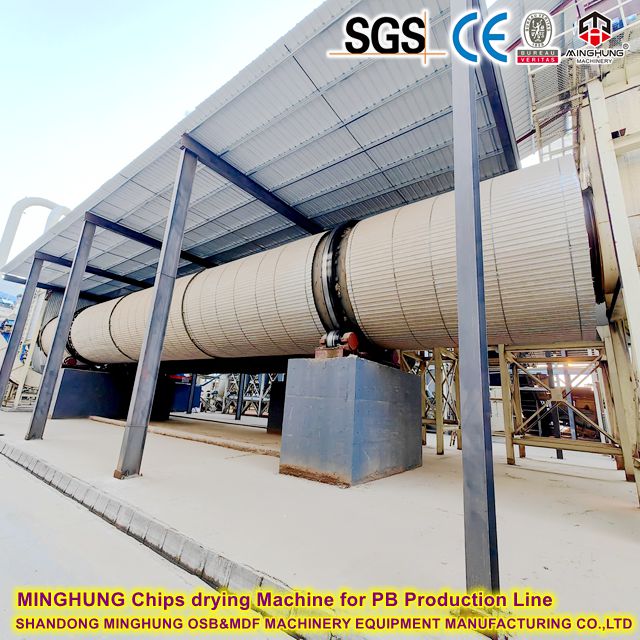

Rotary Drum Dryers (Typically triple-pass): Dry the surface particles and core particles separately, precisely controlling their moisture content to process requirements (e.g., 2-4%). Drying temperature and time must be precisely controlled to prevent particle scorching.

Ring Blenders: Core equipment. Surface and core particles enter separate blenders.

Gluing System: Includes glue tanks, metering pumps, and atomizing nozzles to precisely apply adhesive (typically UF resin) and additives (wax, hardener, etc.). The resin application for core particles is usually lower than for surface particles.

dryer

glue mixer

3. Forming and Pre-Pressing Section (Core Technology)

Mechanical Grading Forming Station: This is the core differentiator for lightweight board production. It typically has multiple forming heads:

First Head: Spreads glued surface fines to form a dense, smooth bottom surface layer.

Second Head: Spreads glued core coarse particles. Through special design (e.g., air or mechanical scattering), the particles are laid down in a very loose and fluffy manner to form the low-density core.

Third Head: Spreads surface fines to form the top surface layer.

Pre-Press: Gently compacts the fluffy mat to give it initial strength for transport to the press and to remove air.

mat forming machine

pre-press machine

4. Hot Pressing and Finishing Section

Continuous Press or Multi-Opening Hot Press:

For a 50, 000 m³ capacity, a continuous press is the more efficient and higher-quality choice. It continuously presses the mat using set pressure, temperature, and speed profiles. For lightweight board, pressure control is particularly critical; too much pressure will crush the core structure, increasing density, while too little pressure will prevent the mat from bonding.

Cooling and Flipping Station: Allows the board to cool evenly, stabilizing internal stresses to prevent warping.

Longitudinal/Cross-Cutting Saws: Cuts the continuous board into required sizes.

Stacker: Automatically stacks the panels.

Sander (Typically 4-6 heads): Sands the panels to precise thickness and a smooth surface, eliminating press marks.

continuous hot press

dryer rack

cross-cut saw

double-sided sander

5. Auxiliary Systems

Thermal Energy Plant: Provides heat for drying and pressing (e.g., gas, biomass).

Dust Extraction System: Installed throughout the line to ensure a clean workshop environment.

Central Control System (PLC/DCS): Automatically controls the entire process; it is the "brain" ensuring production stability and quality consistency.

energy plant

siemens plc

|

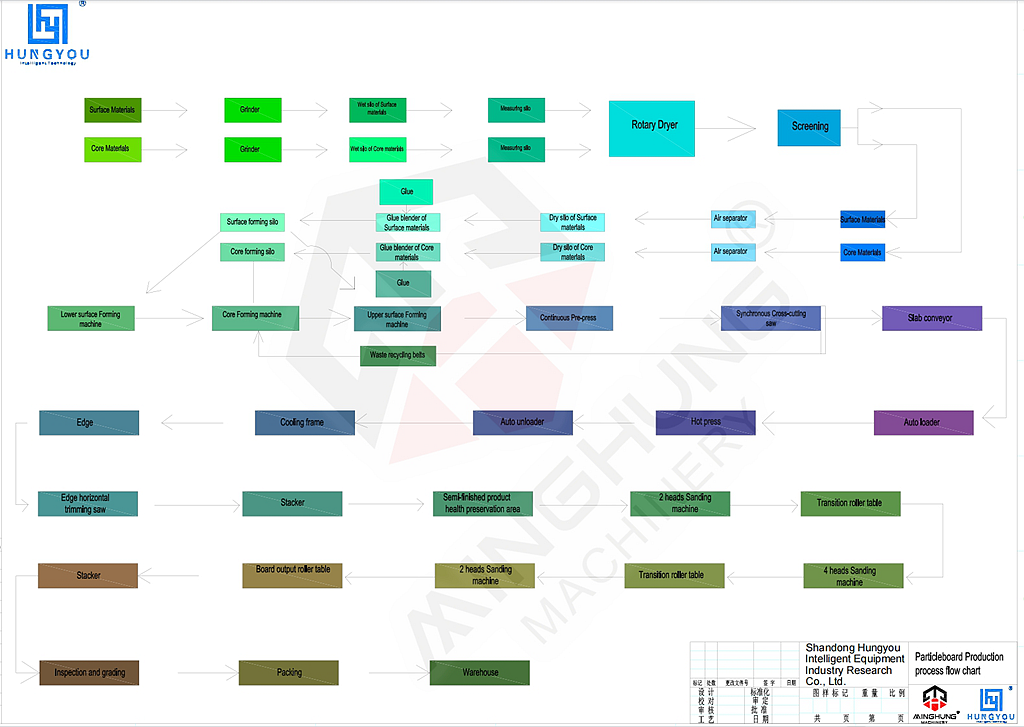

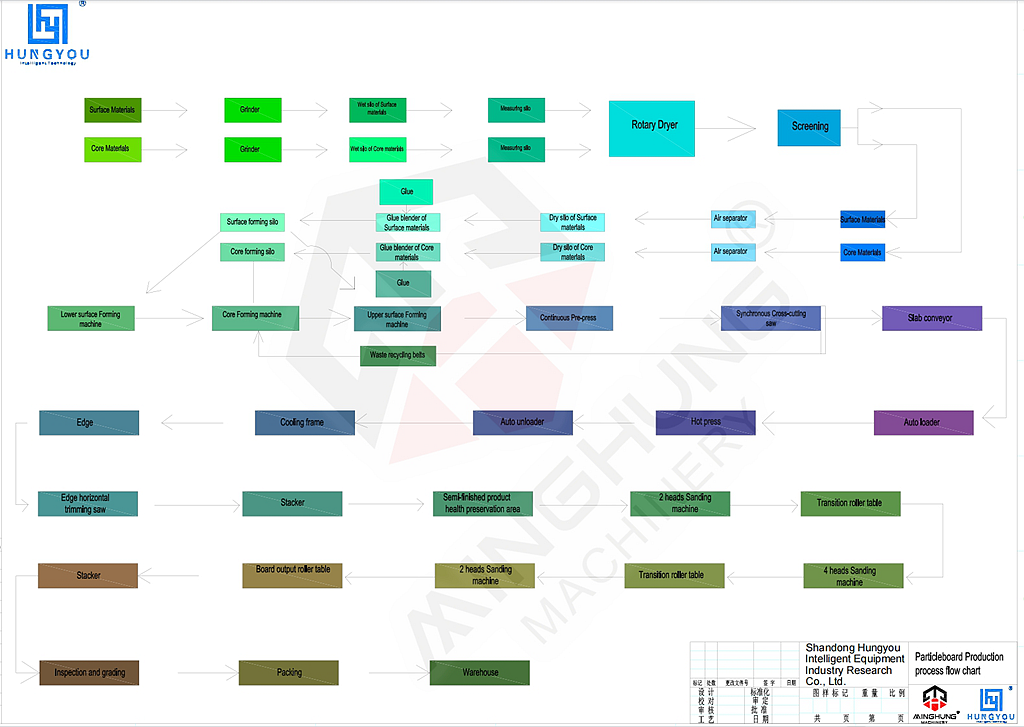

Detailed Production Process Flow

The essence of the lightweight particleboard process lies in "Layered Processing, Precise Control":

1. Raw Material Prep: Wood is chipped, flaked, crushed, and screened to separate surface fines and core coarse particles, which are stored separately.

2. Layered Drying: Surface and core materials are dried in separate rotary drums to target moisture content.

3. Layered Gluing: Dried surface and core materials enter their respective ring blenders to be mixed uniformly with precisely metered adhesive, wax, etc.

4. Layered Forming: This is the most critical step for creating the lightweight structure. The former sequentially lays: Bottom surface fines → Fluffy core coarse particles → Top surface fines, forming a "sandwich"-structure mat. This core is the heart of the lightweighting.

5. Pre-Pressing: The mat is lightly compressed for transport.

6. Hot Pressing & Curing: The mat is pressed under suitable low pressure and high temperature in the press, curing the adhesive and firmly bonding the three-layer structure into a board. Pressure must be carefully controlled to preserve the core's porous structure.

7. Cooling & Cutting: The pressed board is cooled and then sawn into standard-size rough panels.

8. Sanding & Inspection: Rough panels are sanded to precise thickness and a smooth surface, then inspected and packaged for storage.

|

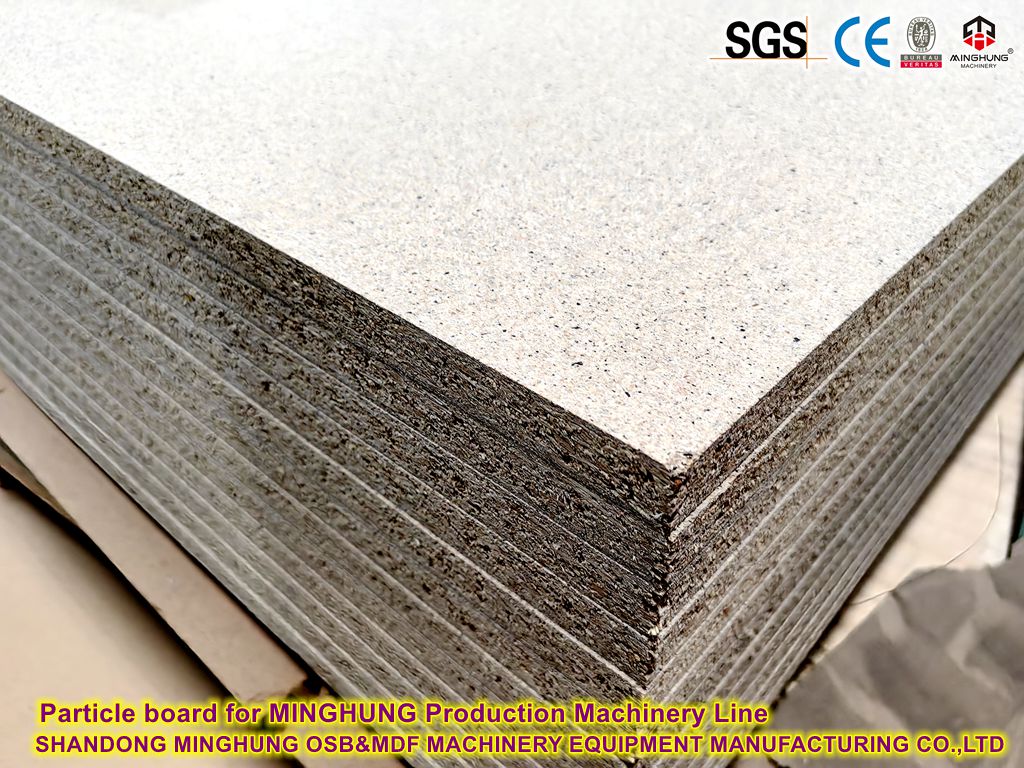

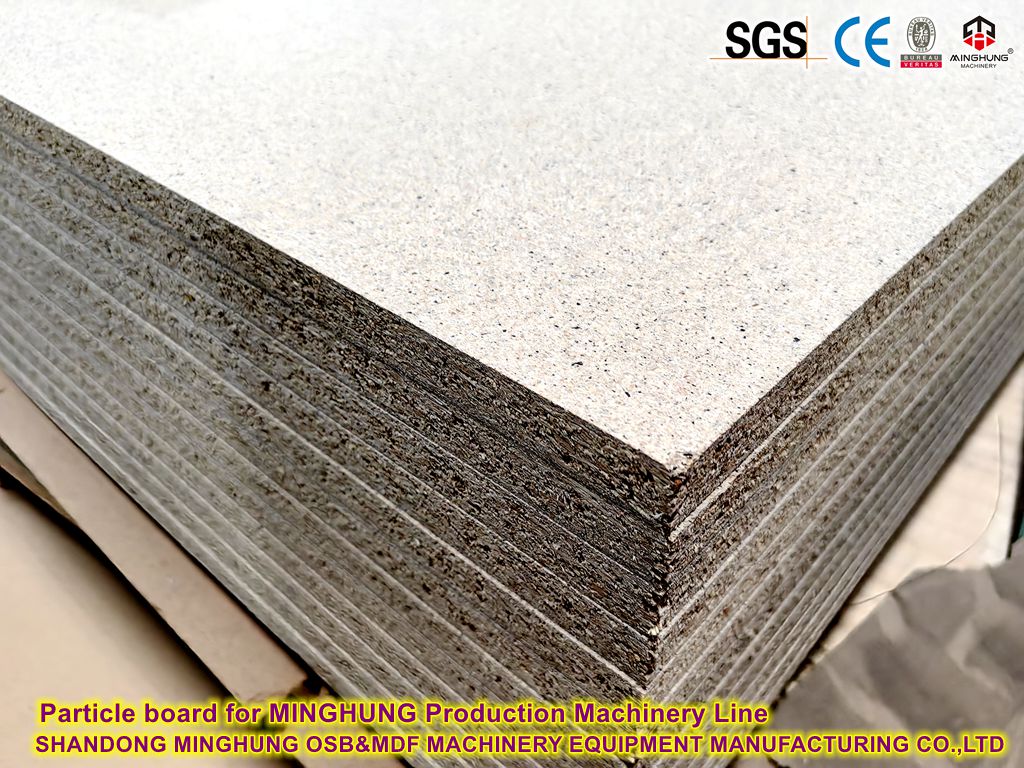

What is Lightweight Particle Boards?

Lightweight Particle Board, as the name suggests, is a type of engineered wood panel with a significantly lower density than standard particle board. Its core characteristic is achieving "lightweighting" through special processes that maximize density reduction while maintaining certain mechanical strength.

Key Metric: Density

Standard Particle Board: Density typically ranges between 550-750 kg/m³.

Lightweight Particle Board: Density typically ranges between 250-550 kg/m³, with some ultra-light boards even falling below 300 kg/m³. It is 25% to 50% lighter than standard particle board.

How is "Lightweight" Achieved?

1. Less Raw Material: Uses fewer wood particles and adhesives per unit volume while ensuring structural integrity.

2. Special Structure: Many lightweight boards employ a three-layer structure: two dense surface layers and a very loose, porous core layer. This fluffy core is key to reducing weight.

3. Additives: Lightweight materials or blowing agents are sometimes added to further reduce density.

|

Key Characteristics

1. Light Weight: Its most prominent advantage. Facilitates transportation, handling, and installation, reducing logistics costs and labor intensity.

2. Good Thermal and Acoustic Insulation: The porous internal structure makes it a poor conductor of heat and sound, ideal for partitions, door cores, and other applications requiring insulation.

3. Easy to Work With: Softer texture makes it easy to saw, drill, and shape, causing less tool wear.

4. Eco-Friendly: Consumes less raw wood material to produce the same volume of board.

5. Cost-Effective: Generally lower material costs.

|

Primary Applications

Due to its properties, lightweight particle board is generally not used for load-bearing or high-wear furniture (e.g., tabletops, shelf boards) but is primarily used for:

1. Interior Door Cores: As filler material for interior doors, reducing door weight while providing sound and thermal insulation.

2. Partition Walls: For non-load-bearing partitions in offices, hotels, etc.

3. Furniture Components: For non-load-bearing parts of furniture, such as cabinet sides, drawer bottoms, door cores, and furniture backs.

4. Exhibition and Display Props: For constructing booths, stage sets, and other temporary structures that require quick setup and teardown.

5. Ceiling and Wall Panels: For decorative ceiling and wall cladding.

|

Product Packaging

|

Application Video

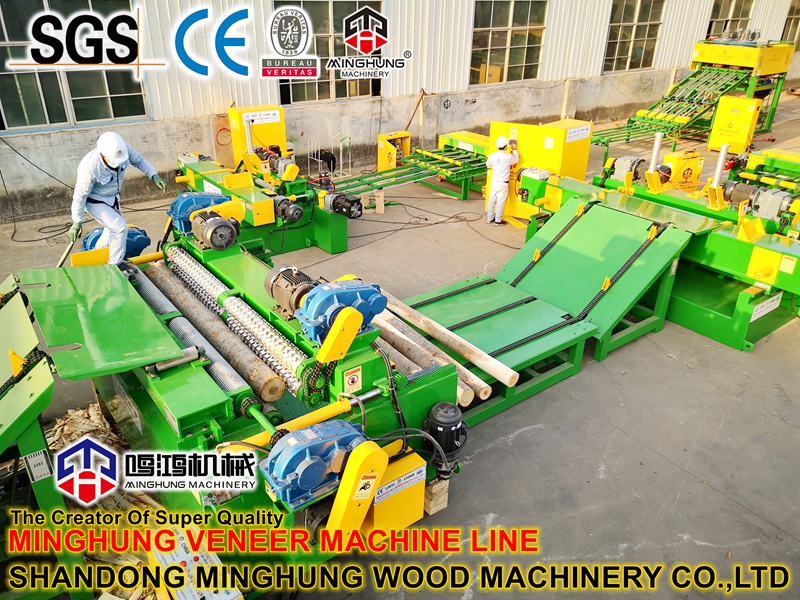

Minghung chipboard production line

|

Comment & FAQ

Q:What can you purchase from us?

A:Particle board production line, directional particle board production line, medium/high fiber board production line, hot press, preforming press machine, plywood production line, automatic production line for hot press, veneer dryer, hot press, cold press machine and other woodworking machinery.

Q:How long the production time?

A:If one set machine,3-4 months;If the full production line 6-8 months.

Q:What are your advantages?

A:We have rich experience in the market, with the same cost, we do better because we have strict control of the production process. We have an independent inspection department to check the quality.

Q:What after-sales services can we provide?

A:After-Sales Service & Support

Global Delivery: Export packaging (wooden case/steel frame) provided, supports CIF/FOB terms, assists with customs clearance documentation.

Installation & Commissioning: Dispatch experienced engineer teams to the customer's factory for installation guidance, equipment commissioning, and trial production.

Technical Training: Comprehensive theoretical and practical training for customer's operators, maintenance, and management staff until they can operate independently.

Warranty Commitment: 12-month warranty for the whole machine, lifelong technical consultation and paid spare parts supply.

Remote Support: 7x24 online technical consultation available, with remote diagnostics and troubleshooting via video call.

|

Company Profile

Shandong MingHung OSB&MDF Machinery Equipment is a China professional factory who specilize in manufacturering and offering Wood based panel machine, including OSB making machine, MDF making machine, and Chipboard /PB making machine.

Our factory with the advanced processing lathes, Mature production technology, and Professional engineers and technicians, and independent ability of reasearch and development, and quickly service, ensure that we have the ability to offer you the suitable and good woodworking machinery as different conditions and requires.

|

Certifications

|

Customer group photo

If interested please contact us for a quote.

Our contacts:

Whatsapp: +8618769900191 +8615589105786 +8618954906501

Email: osbmdfmachinery@gmail.com