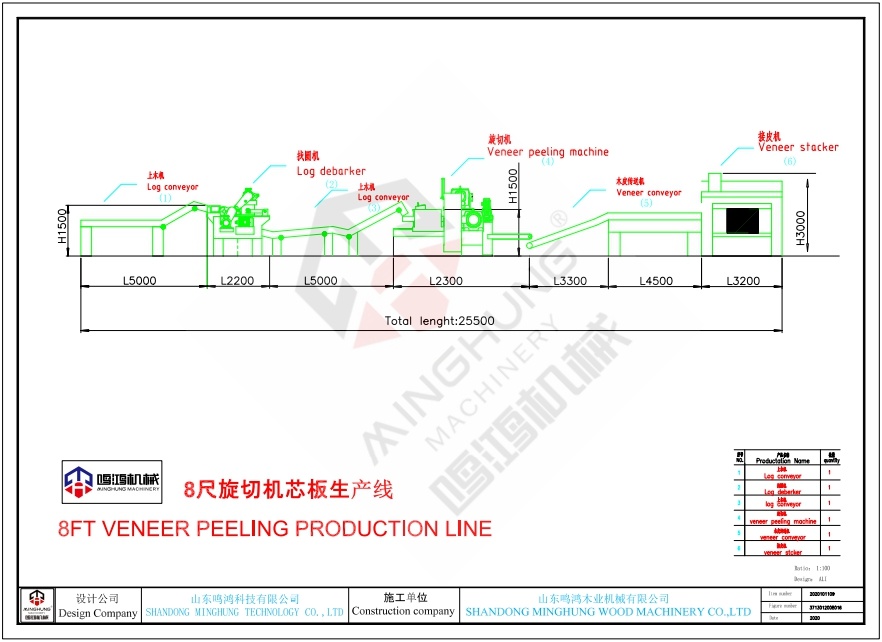

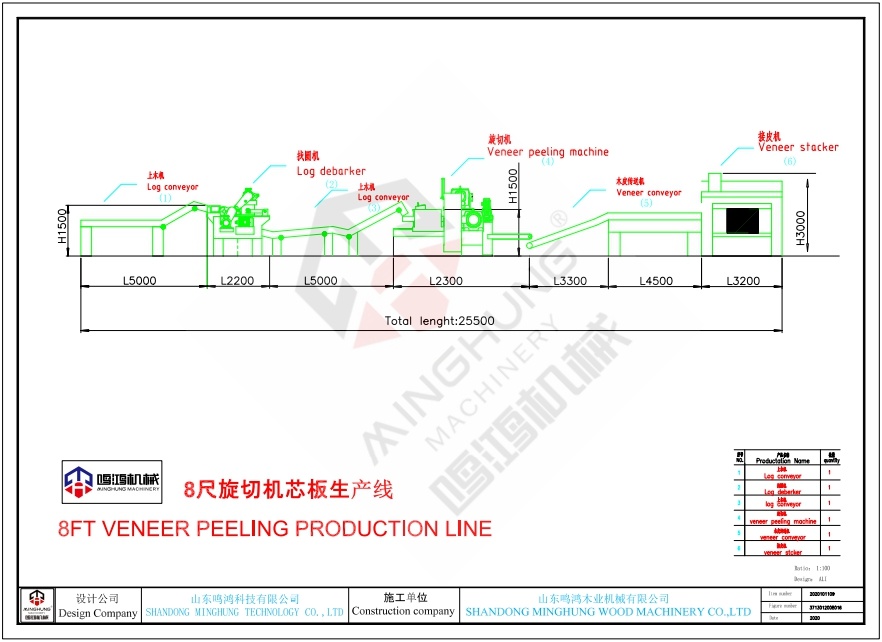

8Feet Wood Veneer Peeler with Good Quality For save your precious time, welcome directly tell me your requires about veneer peeling machine,

The basic principle of rotary cutting and related technology research. 2.1 The principle of rotary cutting The wood rotary cutting trajectory is related to the height of the knife. When the height of the knife is equal to 0, the trajectory of the rotary cutting is an Archimedes spiral; when the height of the knife is a negative value And when it is equal to the unit corner feed, the rotary cutting trajectory is a circular involute; when the tool height is greater than 0 and is not equal to the unit corner feed, the rotary cutting trajectory is a general involute. When the tool installation height is equal to 0 or equal to the negative unit angle feed, the thickness of the rotary cut veneer is relatively uniform, so during the application process, adjust the installation height to 0 or negative unit angle feed to obtain higher machining. veneer quality. 2.2 Research and development of control software and application software The PLC system of the control core of MINGHUNG CNC hydraulic double-axis rotary cutting machine, and the general-purpose programmable logic controller of WICHI introduced Siemens technology, which solved the accuracy, stability and reliability of motion control. The key issues such as storage information capacity; the all-digital DC regulator is an all-digital device that directly supplies power to three-phase AC power, and is used to power the armature and excitation of adjustable-speed DC motors, and can be expanded by paralleling SIMOREG rectifiers (can Select the self-optimizing process for parameter setting, monitoring and diagnosis, realizing input and output functions and safe parking); WICHI series servo controllers can enable the spindle to have all the functions of the servo axis and realize the synchronous drive of the spindles. 2.3 Mechanical structure design and processing technology research Research and development and design of knife door mechanism, etc. In order to ensure the stability of the machine tool and the precision of rotary cutting veneer, the key components are processed by CNC machining centers or special machine tools to ensure the processing accuracy. 2.4 Research and development of hydraulic technology The research on the stability of the hydraulic system mainly includes the research on pressure compensation and impact momentum. Through these researches, the stability of the hydraulic system during operation is effectively guaranteed, the loss of the system is reduced, and the problem of oil Fluid fever problem.

Strong, Heavy Duty, Accurate thickness 8feet veneer peeling machine

For producing good quality wood veneer, it has high requires of veneer peeling machine, according to wood material, diameter, thickness you want and others, veneer peeling machine will have different configuration.

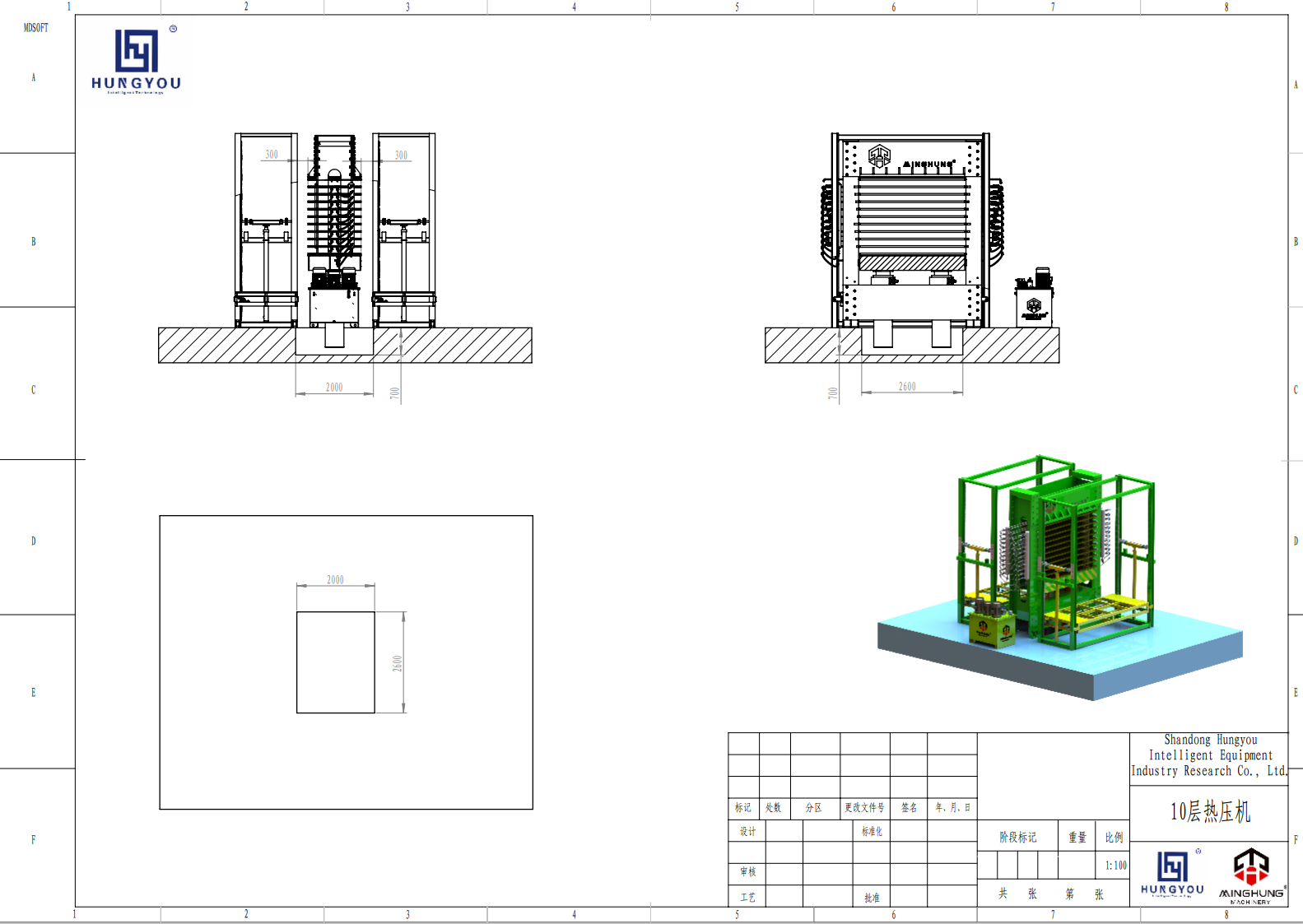

8FEET Veneer peeling machine, everytime we produce machine for our clients, we do better. 8feet veneer machine can peel log length 2600mm, the structure of veneer peeling machine is very strong to peel hardwood, the most important thing is: can help you produce very accurate wood veneer. which will be very helpful for your business | name | veneer peeling machine |

| max log length | 2600mm |

| max log diameter | 600mm |

| thickness | 0.3-3.5mm |

| speed | 48m/min |

| power | 60.5kw |

| weight | 13t |

Character of machine parts:

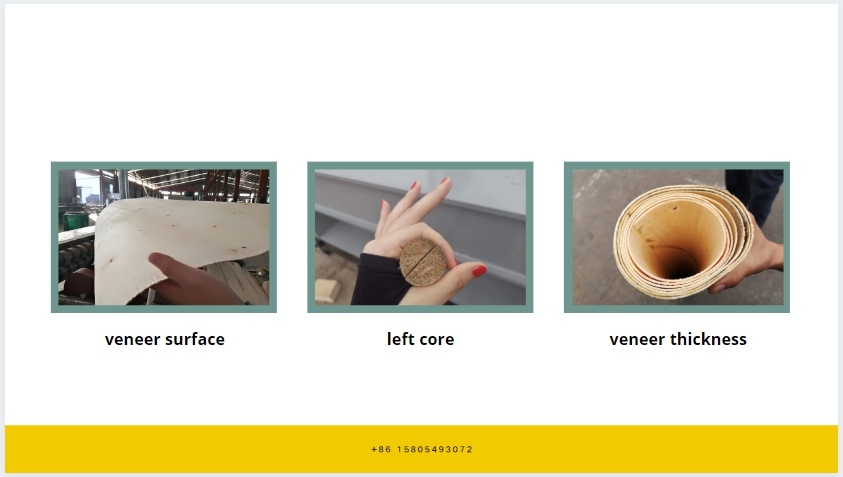

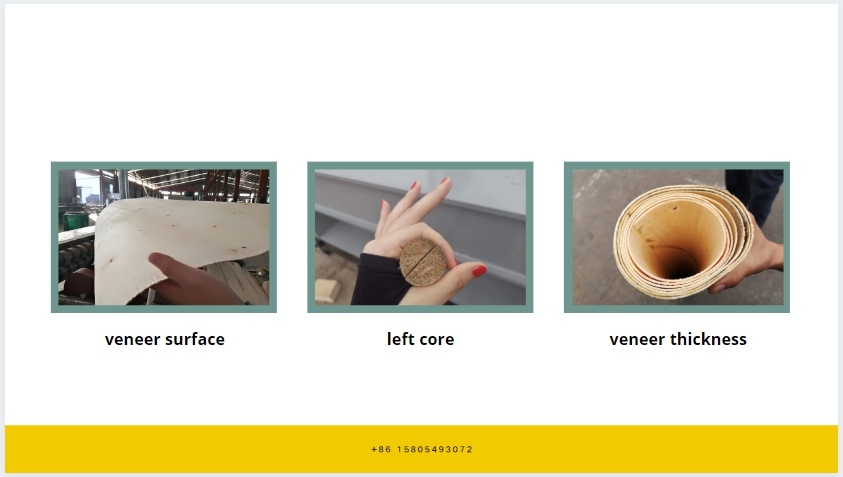

Veneer show:

The purpose buy veneer peeling machine, is can producing good quality wood veneer, whatever you use by yourself for making plywood, or you sell to plywood factory, this will be helpful for your business.

And this what our factory insist do, make veneer machine better and better, help our clients business going better and create much benefits.

Everytime when we finish production of veneer lathe machine, we will test machine to make sure it is in good conditions, and as we thought, the veneer thickness is very accurate, and the surface very smooth. Certification:

All our veneer machine and plywood machine have CE and test report. and we will offer all documents for you do custom clearance.

With many years improvement and development, our factory has been one of the top suppliers in China, with professional designers and experienced workers, good sales team and after-sales team, we have ability, confident and sincere offer you good veneer machine and plywood machine.

Our machine includes: wood log debarker, veneer peeling machine, vacuum veneer stacker, knfie grinder, veneer dryer machine, veneer roller dryer, veneer mesh dryer, glue spreader, cold press machine, hot press machine, plywood edge cutting saw machine, sanding machine, calibrating machine, polishing machine, lift table.

Before order machine, we welcome you come to visit our factory and check machine by yourself. once we start cooperate, we have become your good partner and friend always, because we know the world is so big, we cherish this relationship, and we will spare no efforts to offer you good machine and help your business develops better and better. Machine show:

veneer peeling machine has different types, some suitable for peeling softwood like poplar, some suitable for peeling hardwood,

some is common type, some is high configuration.

we not offer you the most expensive veneer machine, we offer you the most suitable machine.

we focus on each production step, try our best make machine well.

When we start cooperate, we will offer you life span service, always be there help you solve problem and give professional suggestions.

when machine after custom clearance, soon reach your factory, our engineer will prepare go to install your machine, and teach your worker how to operate and maintain.

Before we produce your machine, our engineer will be together have a meeting discuss how to design your machine, which place we can upgrade again, which place we can make it stronger again. so we can promise the machine offered to you, must very good quality and good working conditions.

>>> Before delivery, we will test veneer machine and send you test video.

>>>When loading, we will share loading pictures with you.

>>> After ship leave, we will offer container and ship information to you. Some Question you may want to know: 1> Warranty 2 years for main parts.

2> Production time 1 month

3> Installation

our engineer can go to install machine.

4> Documents

All you need for do custom clearance, we all offer.

5> Payment terms

T/T. L/C

6> Customize machine

except the standard size 4feet and 8feet, yes, we can customize veneer machine.

Contacts: whatsapp: Mark : +8618769900191 Ali : +8615589105786 Lucinda: +8615805493072

email: minghungmachinery@gmail.com