Woodworking Machinery LVL Plywood Machine

What is LVL sheet?

LVL laminated veneer lumber (Laminated Veneer Lumber,) is a material formed by laminating thick veneers along the direction of the grain, hot pressing and gluing, and then sawing. can make up

Artificial fast-growing wood has shortcomings such as soft material, low strength, and large size variability, so as to realize the optimal use of inferior wood and the large use of small wood, and alleviate the conflict caused by the shortage of wood.

Process principle: LVL (Laminated Veneer Lumber) is a material formed by laminating thick veneers along the grain direction, hot pressing and gluing, and then sawing. It is similar to the production process of plywood

Recently, the veneer preparation process is almost the same, and the main difference lies in the blank formation, hot pressing and post-processing processes.

1. Rotary cutting board The raw wood is cut into veneers with different specifications and a thickness of 1-3 mm.

2. Drying and drying The veneers cut into various specifications are dried in the air, and then leveled and dried by a drying machine at about 120 degrees. The moisture content of the veneers is controlled at 8%-10%.

3. Splicing board The veneers that have been leveled by various ovens are spliced into a certain length of wide-band veneer through the inclined arcade machine according to the requirements of the production products.

4. Glue coating The veneer after drying and leveling the inclined street is glued by a glue coating machine. The glue is phenolic glue, and the formaldehyde content does not exceed 1mg.

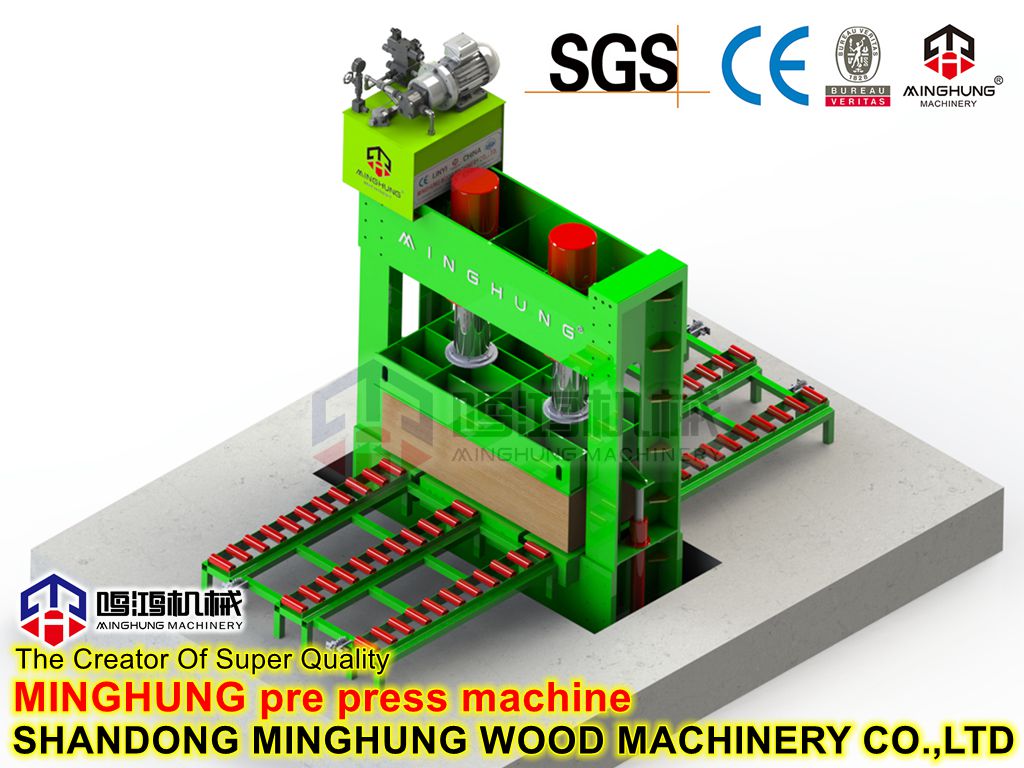

5. Laying board cold pressing According to the product requirements, the glued veneer is laid into a certain number of layers parallel to the direction of the wood grain, and formed by cold pressing.

6. Hot pressing The cold-pressed laminated board is hot-pressed at a temperature of 160 degrees Celsius for a certain period of time through a 1500-ton hot press, and the glue is heated and cured to form a laminated board.

material.

Process principle: LVL (Laminated Veneer Lumber) is a material formed by laminating thick veneers along the grain direction, hot pressing and gluing, and then sawing. It is similar to the production process of plywood

Recently, the veneer preparation process is almost the same, and the main difference lies in the blank formation, hot pressing and post-processing processes.

1. Rotary cutting board The raw wood is cut into veneers with different specifications and a thickness of 1-3 mm.

2. Drying and drying The veneers cut into various specifications are dried in the air, and then leveled and dried by a drying machine at about 120 degrees. The moisture content of the veneers is controlled at 8%-10%.

3. Splicing board The veneers that have been leveled by various ovens are spliced into a certain length of wide-band veneer through the inclined arcade machine according to the requirements of the production products.

4. Glue coating The veneer after drying and leveling the inclined street is glued by a glue coating machine. The glue is phenolic glue, and the formaldehyde content does not exceed 1mg.

5. Laying board cold pressing According to the product requirements, the glued veneer is laid into a certain number of layers parallel to the direction of the wood grain, and formed by cold pressing.

6. Hot pressing The cold-pressed laminated board is hot-pressed at a temperature of 160 degrees Celsius for a certain period of time through a 1500-ton hot p

Laminated Veneer Lumber (LVL for short) is a veneer made by rotary cutting. The blanks are assembled in sequence in the direction of the grain, and the ends are mitered, lapped or butted, and then pressed by processes such as gluing and hot pressing. It is a high-strength structural material with flexural strength of 18MPa, shear strength of 1.7MPa, and elastic modulus of 10000MPa. VL has the characteristics of uniform engineering performance and flexible specifications. It is superior to solid wood and is especially suitable for VL is especially favored by plywood manufacturers and veneer manufacturers on large-span wooden structures, and its consumption is expected to increase steadily in the future. It can make full use of artificial fast-growing forests and medium and small diameter logs to produce high value-added products.

LVL can be divided into two main categories: structural (ie load-bearing members) and non-structural (ie non-load-bearing members). The original structural material LVL was only used for simple beams, and now it is more and more widely used, such as structural frames, I-beams and other composite products. The main difference between non-structural LVL and structural LVL is that it cannot be used for load-bearing structures, but only for furniture components, stair components, door and window frames, etc. LVL has various specifications and a wide range of thicknesses. The thickness range of structural material LVL is mostly 2-5mm, the maximum thickness can reach 150mm; the width range is 100-1800mm; the length range is 2500-25000mm, even infinite. The size of the non-structural material LVL is usually 5 to 50 mm in thickness, 75 to 150 mm in width, and 300 to 600 mm in length. When producing a 4" X 8" LVL, a plywood plant can produce a cost-effective and dimensionally flexible LVL product with a small investment using most of the existing machinery and equipment.

The strength-to-weight ratio of structural material LVL is better than that of steel. The LVL formed by the parallel grain can reproduce the anisotropic characteristics of the wood to the greatest extent, and the longitudinal strength of the wood can be fully utilized when the structure is stressed. Because the knots and veneer cracks of the wood itself are dispersed and evenly distributed in the product, it has uniform mechanical properties, and has the characteristics of uniform quality, stable performance, accurate size and consistent straightness unmatched by other structural materials. And the processing is convenient, can be sawing, slicing, chiseling, tenoning, nailing and so on. After flame retardant treatment, the fire resistance is higher than that of steel, the weather resistance is good, and the shock resistance is strong.

Since the laminated structure of LVL greatly reduces the warpage and distortion of the product, it has good dimensional and shape stability.

Whatsapp: +8618769900191 +8615589105786 +8615805493072

Email: minghungmachinery@gmail.com

Website: www.plywoodmachineline.com