|

Product Description

The Rapid Dehydration Plywood Specialized Drying Machine is a high-tech industrial drying equipment engineered with advanced thermodynamic and aerodynamic principles. It is specifically designed to address industry challenges such as long drying cycles, high energy consumption, and uneven moisture content during plywood production. By optimizing hot air circulation, enabling precise temperature control, and incorporating intelligent dehydration technology, this machine achieves rapid, efficient, and uniform drying for plywood, veneers, and other wood-based panels. It is the ideal solution for modern wood processing enterprises aiming to enhance product quality, reduce operational costs, and strengthen market competitiveness.

|

Core working principle

The heart of the machine lies in its "Stepwise Temperature Rise + Forced Convection Dehumidification" system.

1. Pre-heating Stage: Employs low-temperature, medium-speed airflow to uniformly pre-heat the panels, preventing cracking and warping caused by rapid surface moisture evaporation.

2. Constant Rate Drying Stage: The system raises the temperature to the optimal drying level. High-power, heat-resistant fans then forcibly circulate hot air at high velocity and uniformity through every layer of the stack. This powerful airflow directly carries away free water from within the panels, achieving rapid dehydration.

3. Conditioning & Balancing Stage: In the final phase, the system automatically adjusts temperature and humidity to "condition" the panels. This balances internal stress and moisture content, ensuring dimensional stability and preventing deformation in subsequent processing or end-use.

|

Key features & advantages

High-Speed Drying & High Efficiency: Unique air duct design and forced convection technology can shorten the drying cycle by over 50% compared to traditional drying kilns, significantly boosting production capacity.

Energy Saving & Eco-Friendly: Utilizes high-efficiency insulation and heat recovery systems to minimize thermal loss. Compatible with multiple heat sources (steam, natural gas, electricity, biomass pellets), offering great adaptability and low operational costs.

Uniform Drying & High Yield: A horizontal or vertical air circulation system ensures consistent temperature and airflow across all points in the drying chamber. This results in highly uniform moisture content for every plywood sheet, effectively preventing bending, warping, cracking, and other defects.

Intelligent Control & Easy Operation: Equipped with a fully automatic PLC and touch-screen control system. Users simply set the drying curve, and the system automatically completes the entire process, providing real-time monitoring and data logging of temperature, humidity, and time, enabling unmanned operation.

Safe, Reliable & Durable: Key components are made of high-quality stainless steel and anti-corrosion materials, ensuring robust construction. Integrated multi-level safety protections (e.g., over-temperature alarm, motor overload protection, fire suppression system) guarantee long-term, stable operation.

Specialized for Plywood: The airflow pressure and temperature curves are optimized for the laminated structure of plywood, protecting the glue line strength while rapidly removing moisture, without compromising bonding effectiveness.

|

Main components

This dryer is a complex system, and its efficient, stable operation relies on the synergy of the following key components:

1. Drying Chamber / Casing

Function: This is the main structure of the equipment, forming an enclosed drying space to hold the plywood and maintain a stable internal drying environment.

Detailed Introduction: Typically constructed from modular insulated panels. The walls feature a "sandwich" structure with an inner and outer layer of color steel or stainless-steel plate, filled with high-density, heat-resistant rock wool insulation. This structure minimizes heat loss, improves energy efficiency, and ensures a safe external surface temperature. The chamber is reinforced with sturdy ribs for structural integrity. The large door is a well-sealed insulated type, equipped with an observation window and high-temperature resistant gaskets.

2. Hot Air Circulation System

Function: Responsible for generating forced, uniform airflow within the chamber, allowing hot air to penetrate each layer of the plywood stack, carrying away moisture for even drying.

Detailed Introduction: This is the core of achieving "Rapid Dehydration". The system includes:

High-Power Circulation Fans: Usually axial or centrifugal fans resistant to high temperatures and capable of generating high static pressure, ensuring sufficient air volume and pressure to force air through tightly stacked panels.

Air Ducts and Nozzles/Grilles: Aerodynamically optimized ducts and uniformly distributed air outlets ensure consistent wind speed and temperature across all points in the chamber, eliminating dead spots.

Circulation Motor: Often controlled by a frequency inverter, allowing fan speed adjustment for different drying stages, enhancing energy efficiency.

3. Heating System

Function: Provides the heat source for the entire drying process; the core of energy input.

Detailed Introduction: Offers high flexibility to suit local energy availability:

Electric Heating System: Heats via electric heating elements/tubes, allowing precise control and clean operation, but with higher running costs.

Gas/Oil Hot Air Furnace: Generates clean hot air by burning natural gas, LPG, or diesel; a common choice with lower operating costs.

Steam Heater: Utilizes existing factory boiler steam for heat exchange via finned tube heat exchangers; economical and eco-friendly.

Biomass Burner: Uses biomass pellets (e.g., sawdust, straw) as fuel, offering the lowest fuel cost, ideal for wood processing plants.

Heat Pump System: Highest Coefficient of Performance (COP), extremely energy-efficient, but requires a higher initial investment, suitable for applications with critical energy demands.

4. Dehumidification / Moisture Exhaust System

Function: Timely exhausts the moisture-laden, humid air from the drying chamber while introducing some fresh, dry air. This continuously lowers the absolute humidity inside the chamber, which is the key driving force for moisture evaporation from the panels.

Detailed Introduction:

Exhaust Fans / Dampers: Automatically controlled by the main system based on preset humidity parameters to open and close, expelling moisture in a timed and measured manner.

Heat Recovery Unit (Available in high-end models): Recovers heat from the exhausted, humid air via a heat exchanger to preheat incoming fresh air, significantly reducing energy consumption.

5. Intelligent Control System

Function: The brain of the equipment, responsible for precisely controlling temperature, humidity, time, and air speed throughout the drying process.

Detailed Introduction: This is key to achieving "High-Quality Drying" and "Automation". It includes:

PLC (Programmable Logic Controller): The core computing unit, stable and reliable, executing complex drying schedules.

Touch Screen HMI (Human-Machine Interface): Allows operators to easily set and modify drying benchmarks (e.g., temperature, humidity, time curves) and monitor all operational parameters and equipment status in real-time.

Sensors: Include high-temperature resistant temperature & humidity sensors (for accurate ambient measurement) and wood moisture content probes (for direct measurement of internal moisture, used for endpoint determination).

Actuators: Control the actions of various components, such as adjusting heater power, opening/closing dampers, and starting/stopping fans.

6. Material Handling System

Function: Used to efficiently and smoothly load and unload the stacks of plywood into and out of the drying chamber.

Detailed Introduction:

Tracks and Drying Carts: The most common method. Plywood is stacked on special drying carts, which are pushed into the chamber on rails.

Forklift Access: For large chamber-type dryers, the floor is designed to be strong and flat, allowing direct loading/unloading by forklift.

Hydraulic Pusher System (In automated models): Uses a hydraulic system to automatically push the stack into the chamber, reducing manual labor.

7. Safety Protection System

Function: Ensures the equipment can safely shut down under any abnormal conditions, preventing accidents.

Detailed Introduction:

Over-Temperature Protection: An independent mechanical thermostat that forcibly cuts off the heating power if the temperature exceeds the safe set point.

Motor Overload and Phase Failure Protection: Protects motors for circulation fans, exhaust fans, etc., from damage.

Fire Protection System: Optional high-temperature alarms, smoke detection, and automatic water spray or CO² fire suppression systems.

Airflow Interlock: Ensures the heating system can only start after the circulation fan is running, preventing heat buildup and equipment damage.

|

Typical applications

Drying various types of plywood (e.g., concrete formwork, furniture-grade, marine plywood)

Rapid drying of veneers

Drying processing for blockboard, particleboard, MDF, and other wood-based panels

Other wood-based sheet materials requiring fast moisture content control.

|

Technical parameters

Applicable Products: Plywood, Veneer, etc.

Drying Capacity: 1 to 50 cubic meters per batch (Custom designs available)

Heat Source Options: Electricity, Natural Gas, Steam, Biomass Fuel, Diesel, etc.

Control System: Fully Automatic PLC + Touch Screen HMI

Final Moisture Content: 8%±2% (Adjustable)

|

Data Sheet

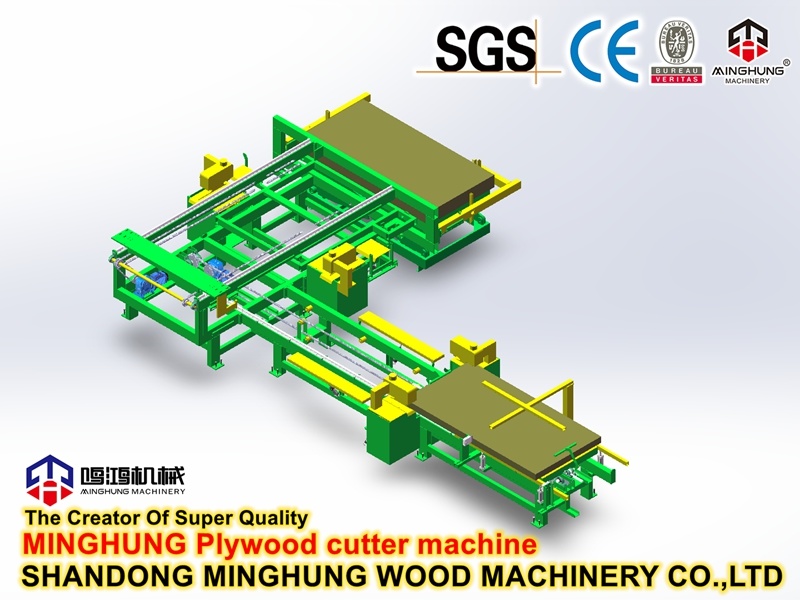

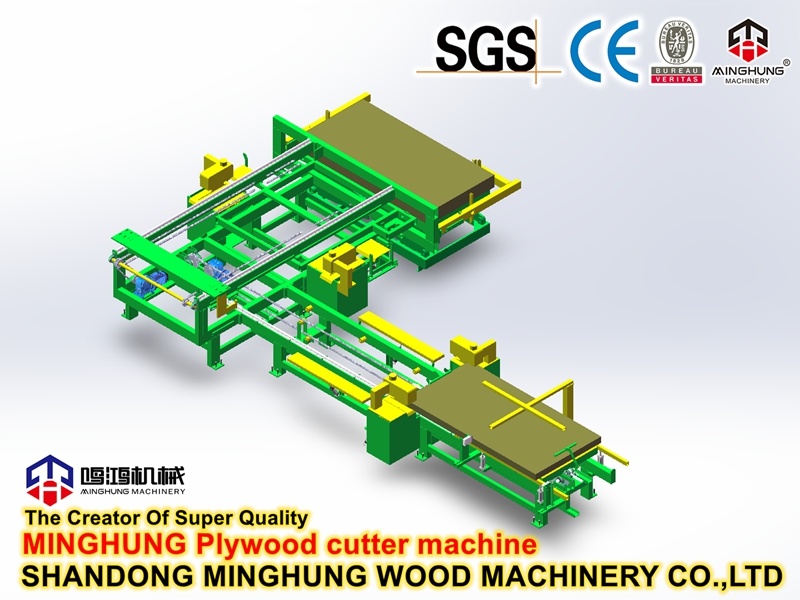

We are Shandong MINGHUNG Wood Based Panel Machinery Co.,Ltd China factory and manufacturer of full sets of Plywood machinery and Veneer machinery.

The machinery we have produced not only includes a complete production line for plywood, but also a full range of production equipment for particleboard, density board, and fiberboard. The main machinery includes peeling machines, chipping machines, rotary cutting machines, drying machines, gluing mixers, laying machines, pre-pressing machines, hot pressing machines, cooling machines, longitudinal and transverse sawing machines, sanding machines, as well as auxiliary machinery such as automatic feeding and discharging systems and lifting platforms.

We are not only equipment suppliers, but also your reliable business partners. We offer a turnkey solution covering factory planning, equipment installation, commissioning, personnel training and after-sales support. Choosing us means choosing quality, innovation and continuous support.