The core working principle of the equipment is analogous to "sharpening a pencil." A pre-conditioned (typically steamed and softened) log segment (usually 1300mm-2700mm in length and 200mm-800mm in diameter) is horizontally mounted between the spindles on the main shaft and set into uniform rotary motion. Simultaneously, a knife carriage holding a sharp peeling knife feeds precisely and steadily towards the rotating log at a rate determined by the preset veneer thickness. The knife edge is parallel to the log's axis, thereby "unwinding" the log into a continuous ribbon of veneer, much like a pencil sharpener.

|

Core Components

1. Base and Bed: Heavy-duty steel structure ensuring stability, precision, and reduced vibration under high load.

2. Headstock and Spindle System: Typically driven by a high-power motor, providing strong, smooth rotational torque via gear or hydraulic systems to clamp and drive the log.

3. Knife Carriage System: Includes:

Peeling Knife: High-strength alloy steel blade requiring extreme straightness and sharpness.

Pressure Bar (Nose Bar): Positioned slightly above and ahead of the knife edge. Its critical function is to apply compressive pressure to the wood fibers before the knife cuts, preventing the veneer from tearing or developing "loose side" checks, which is key to ensuring a smooth veneer back.

Knife Holder and Feed Mechanism: Usually driven by a servo motor or precision hydraulic system, enabling linear feed accuracy up to 0.01mm.

4. Control System: Modern lathes commonly use a PLC (Programmable Logic Controller) and touchscreen HMI (Human-Machine Interface). Operators can easily set target veneer thickness, peeling speed, clearance angle, etc. The system automatically controls the entire peeling process and features fault diagnosis and alarm functions.

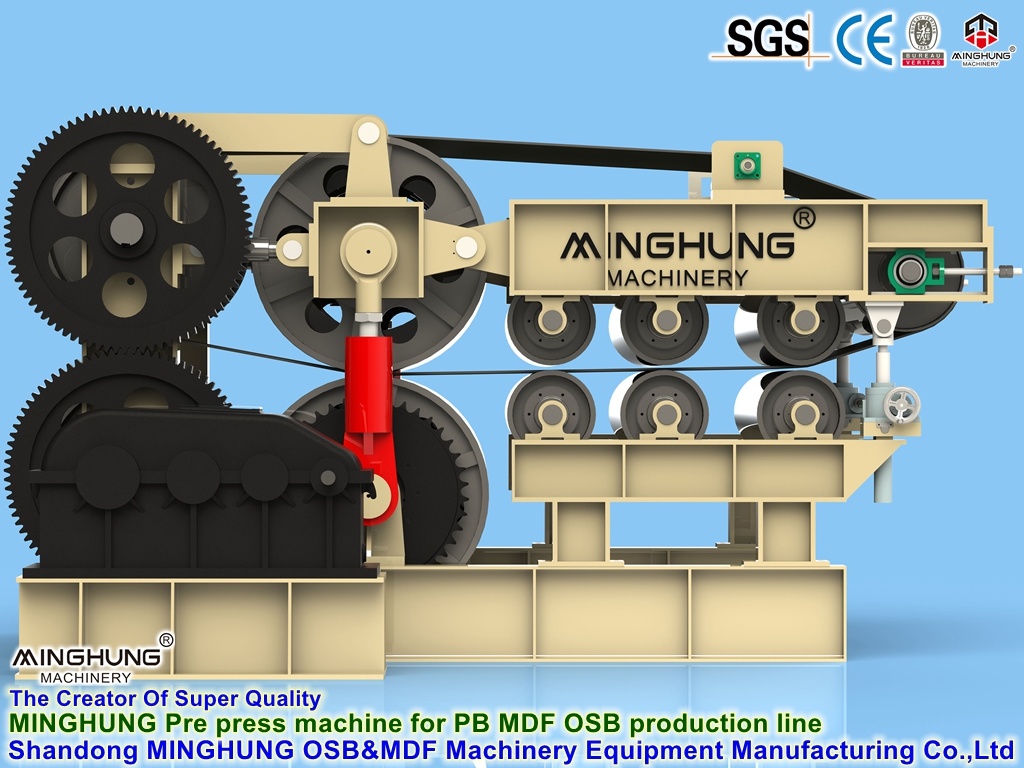

5. Drive and Hydraulic System: Provides power for all machine movements, including spindle rotation, spindle opening/closing, and knife carriage advance/retreat.

6. Auxiliary Devices: Such as automatic log loading/unloading mechanisms, veneer conveyors, and online thickness gauges, which can be integrated for higher automation.

|

Main Features and Advantages

High Precision & Uniformity: Utilizes closed-loop servo control to produce veneer with minimal thickness tolerance (e.g., ±0.05mm), ensuring quality for subsequent plywood pressing.

High Production Efficiency: The continuous peeling process offers extremely high material yield (veneer recovery can exceed 70%) and is significantly faster than slicing or sawing.

Intelligent Operation: Modern machines feature digital parameter setting and one-touch recall of programs for different wood species or thicknesses, simplifying operation and reducing reliance on highly skilled operators.

Excellent Maintainability: Employs a modular design. Core modules like the knife carriage, headstock, and hydraulic power unit can be disassembled and serviced independently. Centralized lubrication points and long-life key components greatly reduce downtime and maintenance costs.

Wide Adaptability: By adjusting parameters, it can process various wood species (e.g., eucalyptus, poplar, pine, oak) and different log diameters, meeting diverse production needs.

Safety & Energy Efficiency: Equipped with multiple safety protections (e.g., emergency stop, guard interlocking). The main drive motor often uses variable frequency drive (VFD) technology to adjust power on demand, effectively reducing energy consumption.

|

Applications

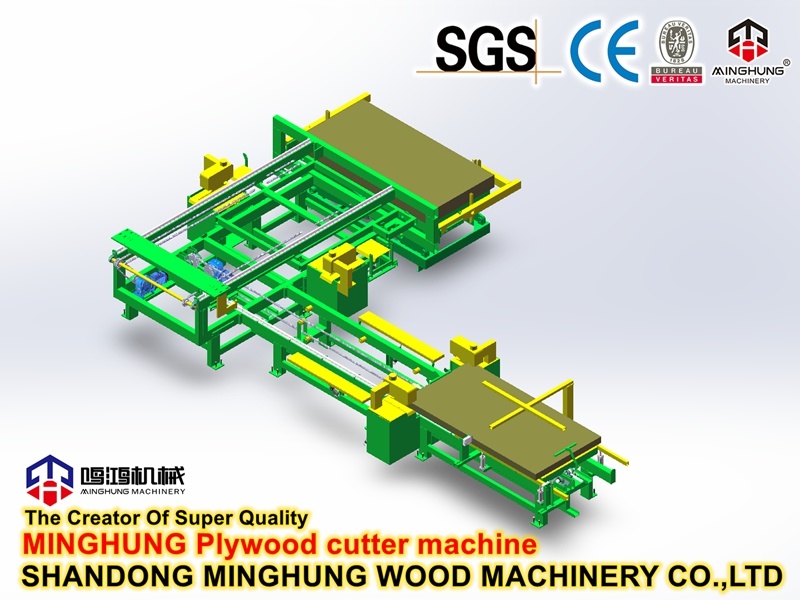

Plywood Manufacturing: Peeled veneers are dried, glued, laid up, and hot-pressed into plywood.

Decorative Veneer (Wood Veneer) Production: Used as surface decorative overlay for furniture, doors, wall panels, and musical instruments.

LVL (Laminated Veneer Lumber): Thicker peeled veneers are glued and laminated with grain parallel to form high-strength engineered wood.

Packaging Board Manufacturing: Using fast-growing wood veneers to make pallets, crates, etc.

|

Certification

We are not only equipment suppliers, but also your reliable business partners. We offer a turnkey solution covering factory planning, equipment installation, commissioning, personnel training and after-sales support. Choosing us means choosing quality, innovation and continuous support.