1. Heat Source System

High-Temperature Heat Pump Unit

Two-stage scroll compressor (Copeland or Danfoss)

Refrigerant: R134a environmentally friendly

Heating temperature range: 40-85℃

COP value: 4.0-4.5 (at 55℃ condition)

Auxiliary Heating System

Stainless steel electric heating tubes (316 material, adjustable power)

Or gas-assisted heating system (optional)

Heat Exchange System

Plate heat exchanger: 316L stainless steel, efficiency ≥85%

Finned tube heat exchanger: Hydrophilic aluminum fins, copper tubes

2. Drying Chamber System

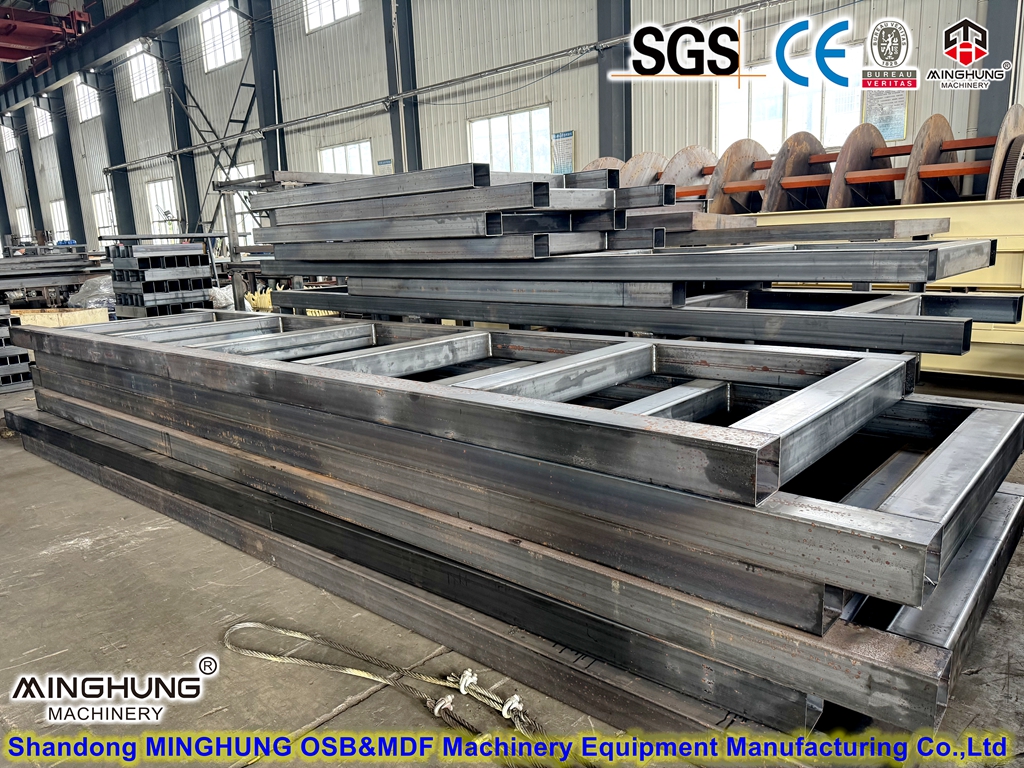

Structural Frame

Main frame: Hot-dip galvanized steel, thickness ≥2.5mm

Reinforcement: 50×50×2.0mm square tube, 600mm spacing

Insulation System

Material: Polyurethane foam, density ≥45kg/m³

Thickness: 200mm

Thermal bridge treatment: Special break design

Inner Liner System

Material: 316 stainless steel plate, thickness 1.2mm

Seam treatment: TIG welding, polishing

Sealing System

Door seal: Silicone rubber double seal, temperature resistance 250℃

Penetration sealing: Special high-temperature sealant

3. Air Circulation System

Ventilation Unit

Fan type: Backward inclined centrifugal fan

Material: Aluminum alloy impeller, stainless steel volute

Air volume: 20000-50000m³/h (adjustable)

Pressure: 800-1200Pa

Duct System

Main duct: 1.0mm galvanized steel, reinforced

Air distributor: Adjustable guide vanes

Filter: G4 primary + F7 medium two-stage filtration

Drive System

Motor: EC permanent magnet synchronous motor, IP55 protection

Transmission: Direct drive, maintenance-free design

4. Intelligent Control System

Hardware Configuration

PLC: Siemens S7-1500 series

HMI: 10.4" color touch screen (1280×800 resolution)

I/O modules: PROFINET bus connection

Sensor System

Temperature sensors: PT100, accuracy ±0.1℃

Humidity sensors: Capacitive type, accuracy ±1.5%RH

Moisture sensors: Online infrared detection, accuracy ±0.5%

Actuators

Electric control valves: Precision actuators, 4-20mA control

Frequency converters: Vector control, accuracy 0.01Hz

5. Heat Recovery System

Heat Pipe Exchanger

Material: Copper tube aluminum fin

Efficiency: 60-70%

Pressure drop: <100Pa

Plate Heat Exchanger

Material: 316 stainless steel

Heat transfer area: Configured by air volume

Self-cleaning design

6. Safety Protection System

Temperature Protection

Three-level over-temperature protection: Sensor + mechanical thermostat + fuse

Temperature difference protection: Alarm when difference >10℃

Electrical Protection

Overload protection: Electronic + thermal magnetic dual protection

Earth leakage protection: 30mA sensitivity

Phase sequence protection: Automatic correction

Mechanical Protection

Fan vibration monitoring: Alarm when vibration velocity >4.5mm/s

Conveyor deviation detection: Automatic correction device