Plywood Machine Knife Grinding Machine Blade Sharpener

We can not promise you our machine price is the lowest in the world, but we can promise you the machine we offered are good quality and suitable for you.

If we just pursue the benefits, yes, we indeed can reduce the production cost through decrease machine quality.

But this is not we want, what we want and our value is: let our machine help more clients business better and better

4 cleaning and maintenance methods for knife sharpeners

In order to do a good job in the cleaning and maintenance of the knife sharpener, the staff must ensure that the relevant problems are found and dealt with in time on weekdays, and the problems are dealt with in a timely manner. Doing a good job of cleaning and maintaining the knife sharpener is also to ensure the quality of the product and prolong its service life, but the wrong cleaning method will outweigh the gains, so our users should understand the precautions for cleaning the knife sharpener!

1. The cleaning work of the knife sharpener includes ensuring that the working environment is clean and tidy, overhauling the machinery and equipment, checking the specific lubrication conditions of each lubricating part according to the lubrication drawing standards, and adding oil lubrication maintenance that meets the oil quality standards in accordance with the regulations.

2. The lubrication of the machine tool should be done in accordance with the standard regulations of the product manual, to ensure that it is replaced once a year, and to clean up the sundries in the oil, remove the oil stains and dirt on each part of the machine and equipment parts, and clean the oil-filtering machines and equipment.

3. Check the household appliances of the grinder machine tool, and clean up the dust, ash, oil stains, oil stains, etc. accumulated on the electrical control components in the household appliance box.

4. The electrical control system circuit of the machine tool should be protected from moisture, water and dust to ensure the integrity of all relevant departments of the machine and equipment.

When you clean and maintain the knife sharpener, after working according to the above methods, you firmly believe that the service life of your knife sharpener will be longer, and the work efficiency will also be greatly improved.

Brief introduction to the safety operation rules of automatic knife sharpener

1. Please

Automatic knife sharpener

The machine is placed on a stable foundation and fixed.

2. For the safety of your electricity use, please install the grounding wire as required.

3. Please check the turning direction of the grinding wheel of the automatic sharpener, it is necessary to be in the same direction as the marked arrow, otherwise, please adjust the power connection method.

4. Please pay attention to the safety of operation when installing the tool! After the tool equipment arrives at the tool table, the interval at which the blade is exposed to the tool table is: 5-8mm. It should not be too much or too little, and the exposed amount of both ends of the tool should be measured together, otherwise it will affect the quality of sharpening! After adjusting the tool, please tighten the press bolt to fix the tool.

5. When installing the tool, please pay attention to the angle of the tool holder. The angle of the tool holder and the tool angle should be the same, otherwise, please adjust the angle of the tool holder. When rotating the tool table, first loosen the fixing bolts at both ends of the tool table, and then roll the handwheel to rotate. After adjusting the angle of the tool table, tighten the fixing bolts of the tool table to fix the tool table. When rotating the angle of the turret, there is an angle ruler at one end of the turret for reference.

6. After the tool is installed, please check the height of the grinding wheel. Before starting the machine, the grinding wheel cannot touch the blade surface and other objects, otherwise, please raise the grinding wheel.

7. An appropriate amount of water or cutting solution should be added to the water tank before operation. No water is allowed to start!

8. Turn on the machine after the above operations are in place. After the machine works normally, gradually drop the grinding wheel. After the grinding wheel touches the tool, pay attention to the amount of grinding. Knife ends.

There should be full-time personnel to operate in order to achieve the best grinding effect.

Magnetic Knife Grinder

The Function:

Grinding knife, make it become sharp again.

The Advantages:

Knife is consumable, after using a while, knife edge will become blunt, if you have this grinding machine, will be conveniently and fast make knife edge become sharp again. Knife is also very important for peeling good quality wood veneer. |

Specification:

4feet magnetic knife grinder:

Knife length: 1500mm

Table size: 1500*160(200)mm

Power: 4kw

Weight: 800kg

Size: 2800*1000*1000mm

8feet magnetic knife grinder:

4feet magnetic knife grinder:

Knife length: 3000mm

Table size: 3000*180(200)mm

Power: 6kw

Weight: 2800kg

Size: 5200*1300*1300mm

Customize machine according to your needs. |

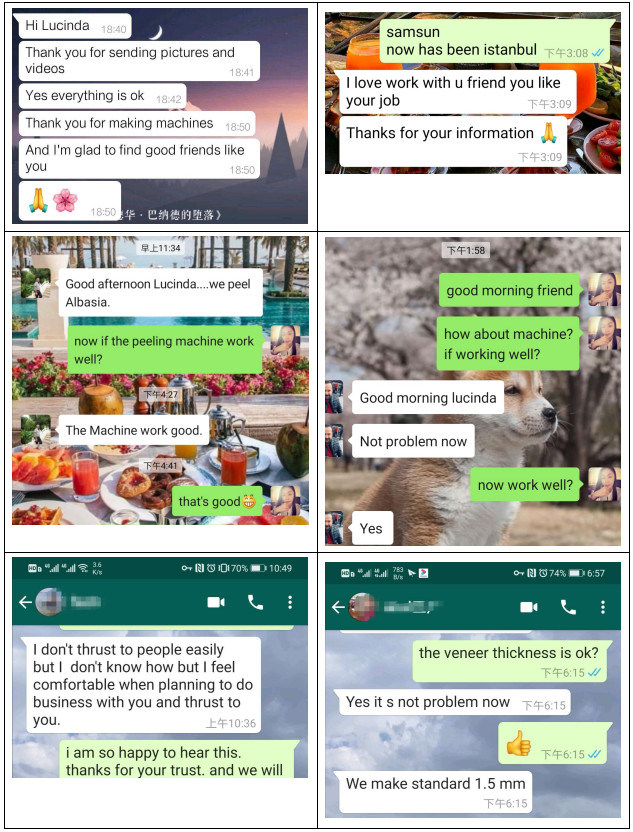

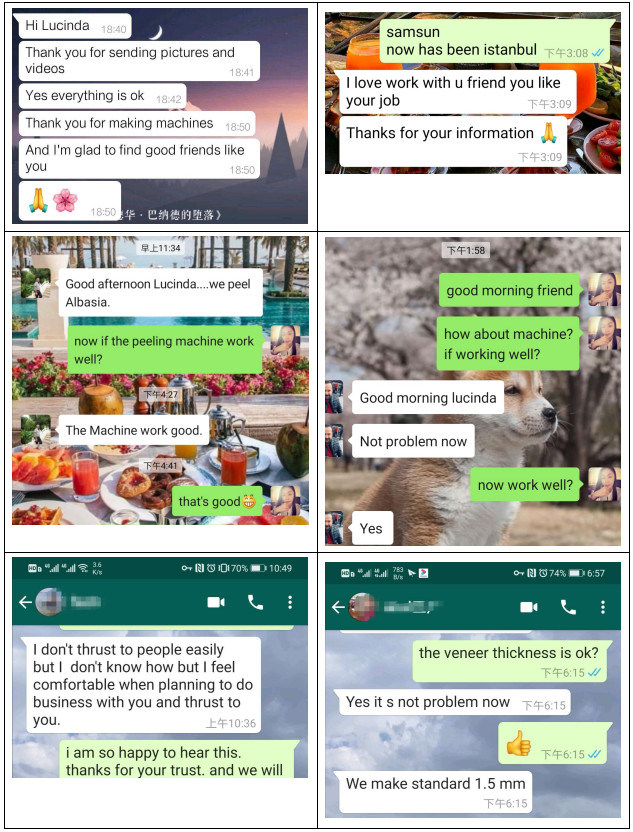

We often talk with our clients about machine working conditions, see if machine is well. If they meet some problems, we will help them solve it in time. The moment when you choose us, we have been your lifetime partners, anytime you need help, we will be there. Clients:

Clients Comment:

Clients Comment:

Delivery:

Delivery:

When machine finish production, we will share test video and pictures to you. When loading, we will send loading pictures to you. After ship leave, we will offer you container no and ship information, and prepare all documents for your custom clearance. Factory:

When machine finish production, we will share test video and pictures to you. When loading, we will send loading pictures to you. After ship leave, we will offer you container no and ship information, and prepare all documents for your custom clearance. Factory:  Professional manufacturer produce the full sets of veneer machine and plywood machine in Linyi City, Shandong Province, China. Including Wood debarker, veneer peeling machine, veneer stacker, veneer dryer machine, glue spreader, cold press machine, hot press machine, plywood saw machine, sanding machine. The value of our factory is: create much more value for clients.

Professional manufacturer produce the full sets of veneer machine and plywood machine in Linyi City, Shandong Province, China. Including Wood debarker, veneer peeling machine, veneer stacker, veneer dryer machine, glue spreader, cold press machine, hot press machine, plywood saw machine, sanding machine. The value of our factory is: create much more value for clients. We have our own morality and principle, insist sincerely treat our clients, regard them as our friend, try help their business.

Profesyonel üretici, Çin'in Shandong Eyaleti, Linyi Şehrinde kaplama makinesi ve kontrplak makinesinin tam setlerini üretmektedir.

Ahşap kabuk soyucu, kaplama soyma makinesi, kaplama istifleyici, kaplama kurutma makinesi, tutkal yayıcı, soğuk pres makinesi, sıcak pres makinesi, kontrplak testere makinesi, zımpara makinesi dahil.

Fabrikamızın değeri şudur: müşteriler için çok daha fazla değer yaratmak.

Kendi ahlakımız ve ilkemiz var, müşterilerimize içtenlikle davranmakta ısrar ediyoruz, onları arkadaşımız olarak görüyoruz, işlerine yardımcı olmaya çalışıyoruz.

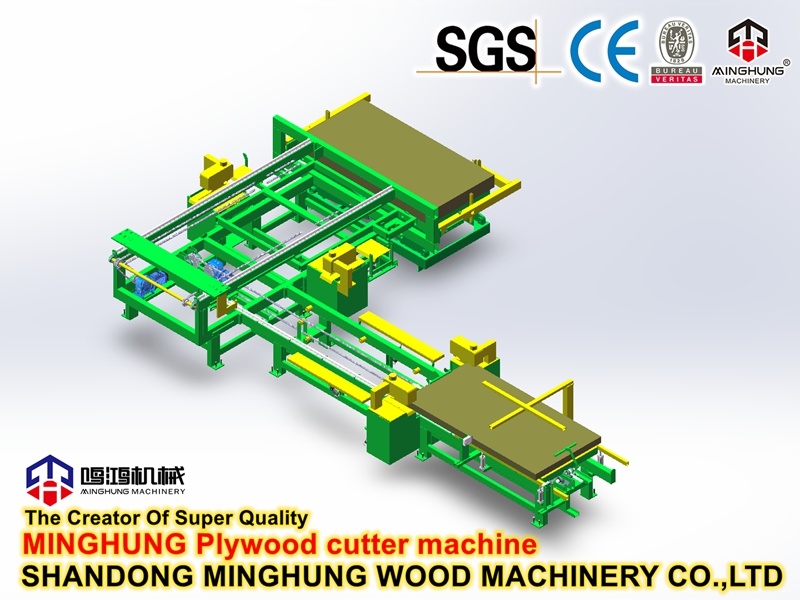

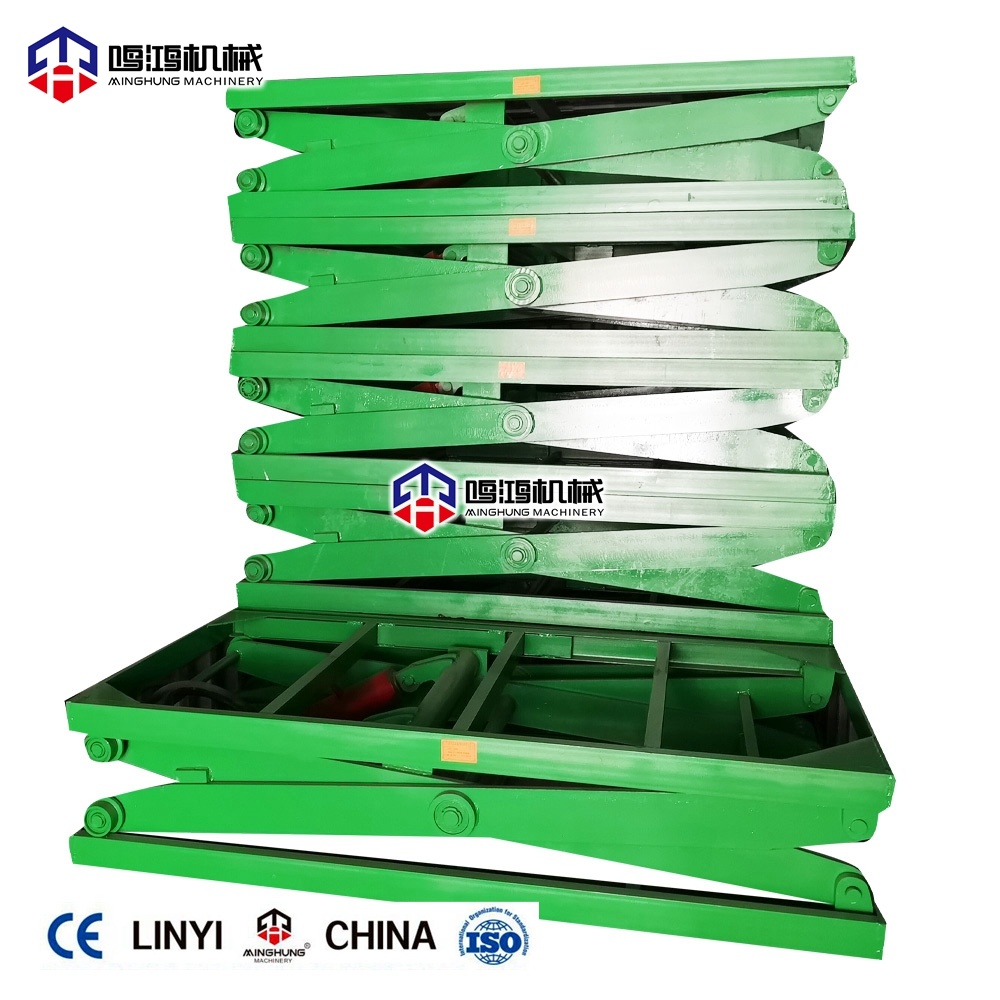

Plywood Machine:

RFQ:

RFQ: | Production Time: |

| 1 month after receive your deposit. |

| Payment Terms: |

30% deposit, 70% before delivery.

100% Letter of Credit. |

| Warranty: |

| 2 years for main parts. |

| MOQ: |

| 1 set |

| Installation: |

| When machine reach your factory, our engineer can go to install |

| After-sales service: |

| Any problem that your worker can not solve, tell us, we will reply you at the first time, |

Contact us: whatsapp: +8618769900191 +8615805493072 +8615805496117

email: minghungmachinery@gmail.com