CE Certified Wood-based Panel Continuous Hot Press Safety Interlocks

MDF(medium density fiberboard)

chipboard/particle board

oriented strand board

Ⅰ. Types of Engineered Wood Panels

Type | Raw Material | Density(kg/m³) | Key Properties | Applications |

PB | Wood chips + UF resin | 600-750 | Low cost, easy machining, weak screw holding | Furniture internals |

MDF | Wood fibers + MUF resin | 720-850 | Smooth surface, carvable, poor moisture resistance | Cabinet doors, moldings |

OSB | Strands + PF resin | 600-680 | High MOR(≥35MPa), waterproof | Wall sheathing, roofing |

Plywood | Veneers + PF resin | 500-650 | Isotropic strength, impact-resistant | Concrete formwork, marine |

HPL | Kraft paper + MF resin | 1,350-1,450 | Abrasion resistance(≥4,000 cycles), chemical-proof | Lab countertops, facades |

Ⅱ. Continuous Press Key Components

Core Systems

Steel Belt:

SUS304 belt (1.2-2.0mm thick), laser-textured surface (Ra=3.2μm)

Tension control (±0.5kN) with hydraulic servo

Heating Platen:

Zoned heating (1.2-1.8m/zone), independent PID control (±1.5℃)

Multi-layer hydraulic cylinders (0-10MPa)

Drive System:

VFD motors (250-800kW) + planetary gearboxes

Safety Frame:

Cast steel frame (stiffness ≥8GN/m) with thermal compensation

Ⅲ. Continuous Press Working Principle

Three-stage Thermo-mechanical Process

1. Compression Zone (Entry):

- High T/P (180-220℃, 5-8MPa) melts resin

- Density compressed from 300 to target (e.g., 650kg/m³ for OSB)

2. Curing Zone (Middle):

- Constant T/P (±2℃, 3-4MPa) for resin polymerization

- Dwell time: `t = L/V` (L=press length, V=belt speed)

3. Stabilization Zone (Exit):

- Stepwise pressure release (2MPa→0.5MPa)

- Water spray cools boards from 200℃ to <50℃

Ⅳ. Press Variations by Panel Type

Parameter | OSB Press | MDF Press | HPL Press |

Max Pressure | 8 MPa | 5 MPa | 12 MPa |

Heating Method | Thermal oil + steam | Pure steam | Electric heaters |

Belt Speed | 15-30 m/min | 20-50 m/min | 3-10 m/min |

Unique Design | Strand orienter | Precision fiber meter | Mirror-finished platens |

Ⅴ. CE Certification Essentials

Standards: EN 848-3:2012 + Machinery Directive 2006/42/EC

Safety Interlocks:

Mechanical:

- Platen position switches (dual magnetic sensors)

- Belt misalignment E-stop (triggered at >5mm deviation)

Electrical:

- Safety relays (e.g., PILZ PNOZ) for dual-channel control

- Maintenance key switches (hardwired power disconnect)

Hydraulic:

- Pressure fault tolerance: Relief valve activates at >110% setpoint

Human-Machine Safety:

- Two-hand control (<0.5s activation interval)

- Laser safety scanners (300mm height, 14mm resolution)

Thermal Protection:

- 50mm ceramic fiber insulation (surface temp ≤45℃)

- Auto-fire suppression (CO₂ discharge ≤100ms)

Emergency Systems:

- Redundant hydraulic brakes (stopping distance <1.5m @50m/min)

- Pressure dump valves (90% release in 0.5s)

Smart Monitoring:

- Bearing temperature tracking (>85℃ alarm)

- Vibration analysis (FFT-based fault diagnosis)

Q:How long the production time?

A:If one set machine,3-4 months;If the full production line 6-8 months.

Q:What can you purchase from us?

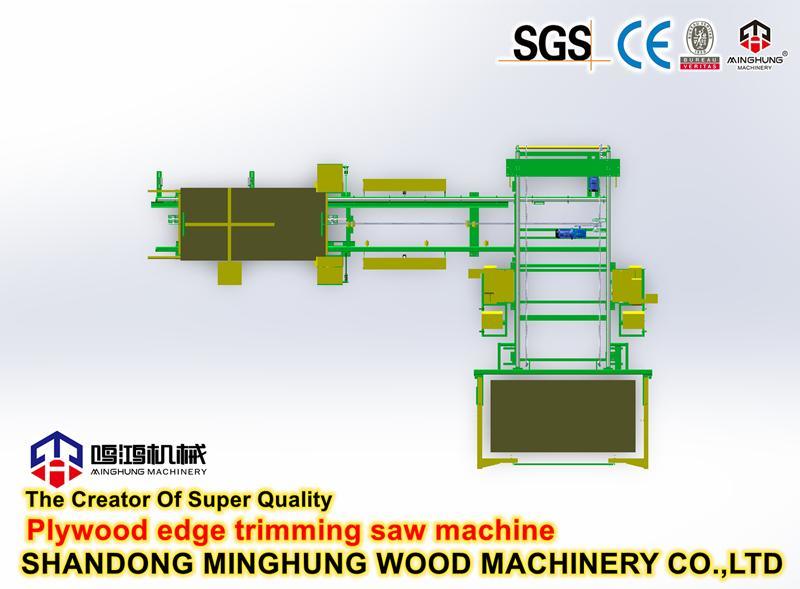

A:Particle board production line, directional particle board production line, medium/high fiber board production line, hot press,preforming press machine, plywood production line, automatic production line for hot press, veneer dryer, hot press, cold press machine and other woodworking machinery.

Q:What services can we provide?

A:Accepted delivery terms: FOB, CFR, CIF:

Accepted payment currencies: USD, EUR, RMB;

Accepted payment methods: T/T, L/C, D/P, D/A, PayPal, Western Union, Escrow;

Languages used: English, Chinese, Spanish, Russian

Customize Your Line! Full-service solution from layout design to production optimization. Request a tailored proposal now.

Whatsapp: +8618769900191 +8615589105786 +8618954906501

Email: osbmdfmachinery@gmail.com