① Fiber Preparation System

Defibrator: 54-inch grinding discs (2500kW power), freeness 18-22°SR

Resin Blending: High-pressure atomizing nozzles (droplet size ≤50μm)

fiber cooking and refining systems for MDF

gluing system

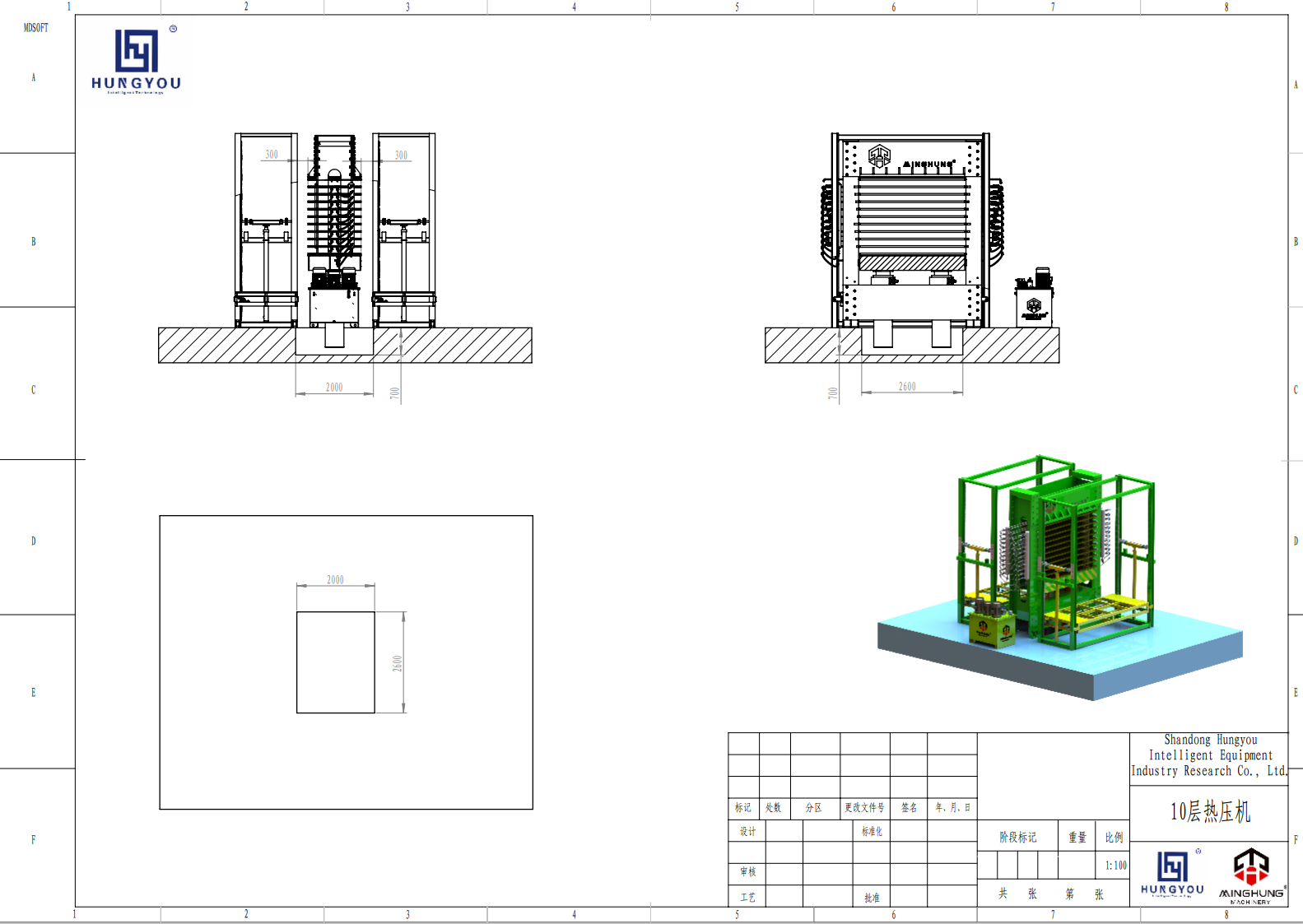

② Forming & Pressing System

Forming Line:

Air-mechanical forming head (mat thickness accuracy ±7%)

Continuous Flat Press:

30-zone hydraulic control (pressure fluctuation <±0.3MPa), platen temp. variation ≤±2°C

mat forming machine

continuous hot press line

③ Finishing System

Cooling Star: 8-tier turnover system (cooling capacity ≥1200㎡/h)

Sanding Line:

Calibrating heads (2 sets) + Finishing heads (5 sets), removal accuracy ±0.05mm

Dryer rack

high density fiberboard sanding machine

④ Intelligent Control System

DCS: Real-time monitoring of fiber moisture (±0.5%), press temp. (±1.5°C)

QA Instruments: Online X-ray densitometer (0.5% res.), laser thickness scanner