1. Particleboard:

1. Particleboard:

Definition: A panel product manufactured under heat and pressure from particles or flakes of wood (or non-wood plant materials like straw) bonded together with a synthetic resin binder (primarily urea-formaldehyde or phenol-formaldehyde resin) and other additives (e.g., water repellents, hardeners).

Characteristics: Utilizes a wide range of raw materials (small-diameter logs, branches, wood residues); uniform structure; good dimensional stability; easy to machine and surface finish (veneering, painting); relatively low cost.

Key Quality Metrics: Density and its distribution, internal bond strength, surface bond strength, modulus of rupture (MOR), modulus of elasticity (MOE), thickness swelling after water absorption, formaldehyde emission levels. These metrics are highly dependent on the hot-pressing process, especially pressure and temperature control.

2. Continuous Flat Press:

2.1 Definition: The core equipment for the continuous production of flat-panel wood-based composites like particleboard and MDF. Its defining features are:

Continuous: The mat (a mixture of particles/flakes and resin adhesive) is fed continuously into the press, undergoing pressing, heating, and curing while in motion. Finished board exits continuously at the opposite end. This fundamentally differs from discontinuous "multi-opening presses" that require cyclic loading, pressing, and unloading.

Flat Pressing: Pressure is applied via two massive, heated platens (usually above and below the mat), ensuring uniform pressure across the board's width and length, resulting in flat surfaces.

Working Principle: The mat enters the press on steel belts. Hydraulic cylinders drive the heated platens to close, applying the required pressure and temperature. The platens are typically designed with a "tapered opening" (wedge zone). As the mat is conveyed through this zone, its thickness is gradually compressed to the target value. It is then held at the set pressure and temperature for sufficient dwell time to fully cure the resin. At the exit end, the platen opening increases, allowing the cured board to exit at the desired thickness.

2.2 Advantages:

High Efficiency: Continuous production enables significantly higher output (modern presses can reach tens of cubic meters per hour) compared to multi-opening presses.

High Quality: More uniform heat and pressure distribution along the length result in superior density distribution (especially through the thickness), smaller thickness tolerances, and excellent surface quality.

Flexibility: Easier switching between different board thicknesses during continuous production (by adjusting the wedge zone opening).

High Automation: Easily integrated into automated production lines.

3. Embodiment of Intelligence:

This is the core upgrade distinguishing modern continuous flat presses from traditional equipment. Its "intelligence" is primarily manifested in the following aspects:

3.1 Intelligent Sensor Network:

High-Precision Sensors: Strategically placed at key points throughout the press to monitor in real-time: pressure (total pressure, zone pressure, pressure distribution), temperature (platen surface, board core), platen position/gap opening, steel belt speed, steel belt tension, hydraulic system status (oil temp, flow, pressure), drive system status (motor current, temp, vibration), etc.

Online Quality Monitoring: Integrated scanners (e.g., X-ray density profilers, NIR moisture meters, thickness gauges) at the press inlet and outlet provide real-time data on mat density distribution, moisture content, and finished board thickness/density profile.

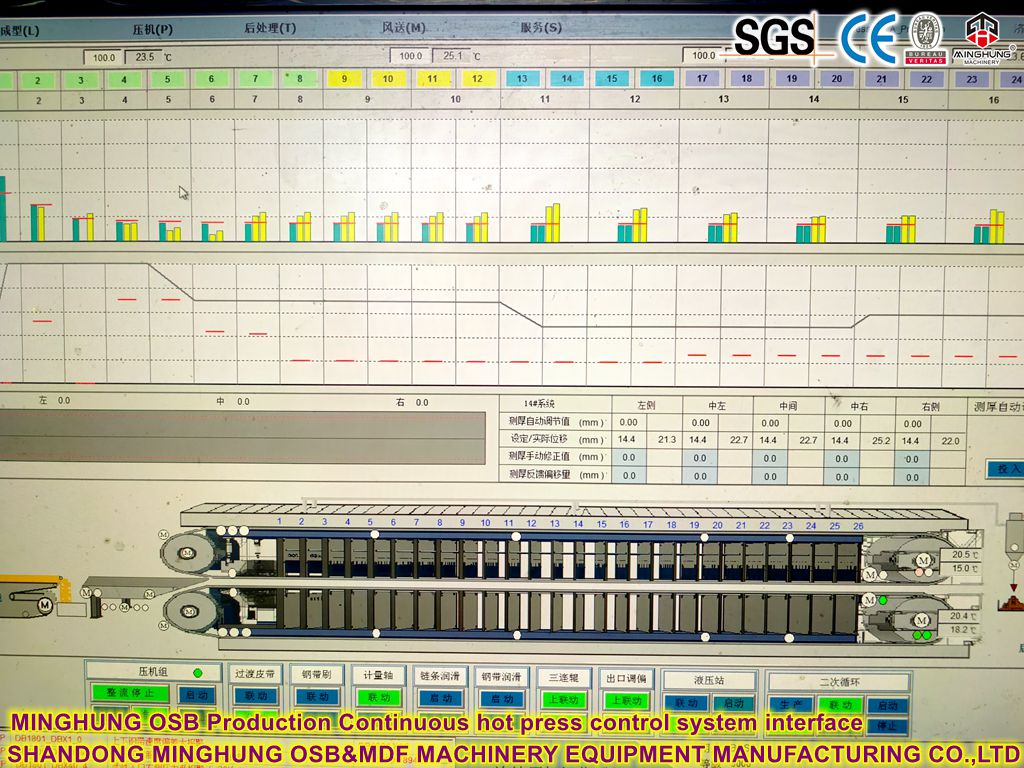

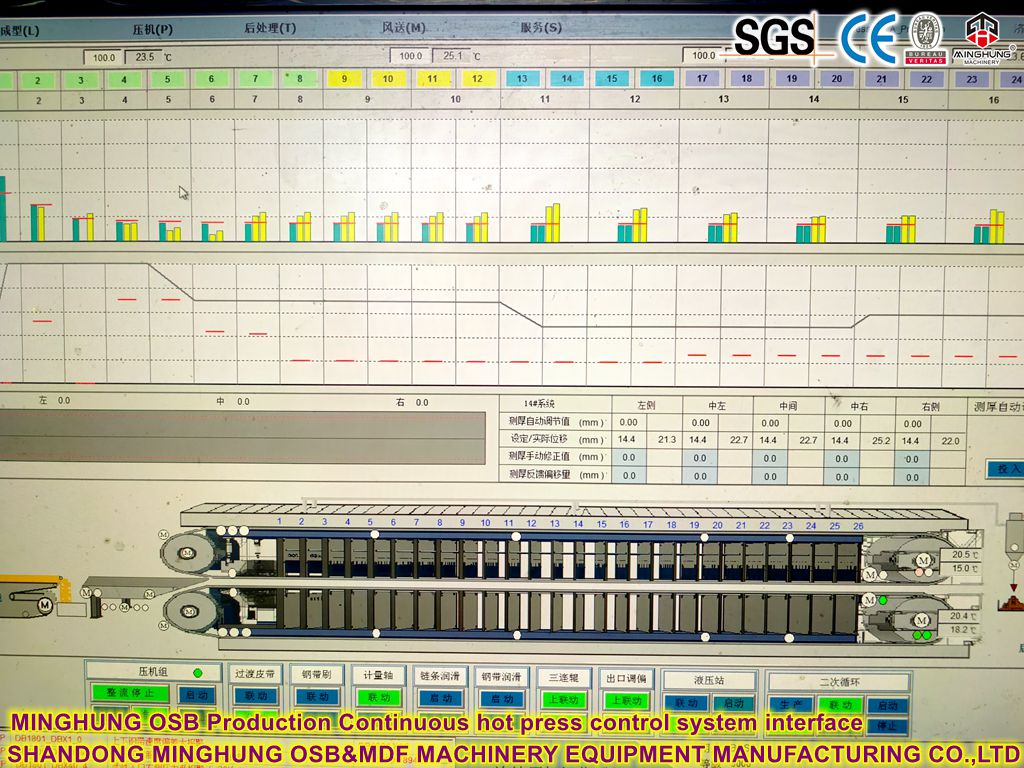

3.2 Intelligent Control System (The Brain):

3.2.1 Advanced Process Control (APC): The control system (typically high-performance PLCs and industrial PCs) uses complex algorithms (e.g., PID, Model Predictive Control - MPC, adaptive control) for closed-loop regulation. This is based on real-time sensor data and preset process parameter models (recipes).

3.2.2 Core Intelligent Regulation:

Precision Zone Pressure Control: The press length is divided into numerous independently controlled pressure zones (often dozens). The system dynamically and independently adjusts the pressure in each zone (via controlling the hydraulic pressure to corresponding cylinder groups) based on mat characteristics (density, thickness, moisture) and online monitoring data. This is crucial for compensating raw material fluctuations and ensuring density uniformity.

Precision Zone Temperature Control: Heated platens are often also divided into heating zones (e.g., steam or thermal oil heated). The system precisely controls the temperature setpoints and flow for each zone based on process requirements and real-time feedback, ensuring uniform and efficient heat transfer.

Speed & Opening Synchronization: Precisely coordinates steel belt speed with the changing gap openings at each zone along the press length, ensuring smooth mat passage through the wedge zone to achieve target thickness and sufficient dwell time in the curing zone.

3.2.3 Adaptation & Self-Learning: More advanced systems can automatically fine-tune pressure/temperature setpoints or control parameters based on online quality results (e.g., exit density profile), compensating for long-term drift or raw material variations. Some systems incorporate machine learning to accumulate data and optimize process models.

3.2.4 Predictive Maintenance: Continuously analyzes equipment operational data (vibration, temperature, pressure fluctuations, current, etc.) using algorithms to predict potential failures of critical components (hydraulic cylinders, bearings, heating systems), enabling proactive maintenance and reducing unplanned downtime.

3.3 Human-Machine Interface (HMI) & Data Analytics:

Centralized Monitoring: Large HMI touchscreen panels display all key parameters, machine status, alarms, and quality data trends.

Recipe Management: Stores and manages optimized process parameters (pressure curves, temperature curves, speed, etc.) for different product specifications (thickness, density, resin type).

Data Logging & Analysis: Vast amounts of production and process data are stored for generating reports, production traceability, quality analysis, efficiency analysis, and continuous improvement initiatives.

Remote Monitoring & Support: Leveraging Industrial IoT (IIoT) technology, authorized personnel (equipment manufacturers, plant HQ) can remotely access machine data for diagnostics, optimization, or technical support.

4. High-Pressure Customization:

This refers to the design and manufacturing of the continuous flat press to be strengthened or specially engineered for higher maximum working pressure – a core performance parameter – based on a client's specific requirements:

Meaning of "High-Pressure":

Indicates the press can achieve and stably maintain a higher maximum system working pressure (typically measured in bar or MPa) than standard models. For example, while a standard press might max at 500-800 bar, a high-pressure customized model could reach 900 bar, 1000 bar, or even higher.

Higher pressure demands significantly stronger structural integrity for the press frame, platens, hydraulic cylinders, and piping systems, requiring higher-grade materials and more precise manufacturing.

Customization Scenarios:

Producing High-Density Particleboard: Boards used for countertops, flooring substrates, or heavy load-bearing structures require higher densities (>750 kg/m³, even exceeding 800 kg/m³). Achieving such high densities necessitates enormous pressure, which may be inefficient or impossible for standard presses.

Special Raw Materials: Processing hardwoods, recycled wood, or non-wood fibers (bamboo, straw) may require higher pressure for effective compression and bonding.

Process Optimization / Efficiency Gains: Higher pressure might allow for shorter pressing times (resin cure rate depends on T&P) while maintaining quality, or enable the use of lower moisture content mats, thereby increasing efficiency or reducing energy consumption.

Ensuring Quality for Thick Boards: Producing ultra-thick particleboard requires overcoming greater compression resistance to achieve sufficient core density and bond strength, making high pressure essential.

Client-Specific Specifications: The client's product standards or end-use applications impose extremely stringent requirements on physical/mechanical properties (e.g., internal bond, MOR) that necessitate high-pressure processes.

Key Considerations for High-Pressure Customization:

Structural Reinforcement: Press frame (columns, crossheads) requires thicker sections or higher-strength steel; platens need increased stiffness and bending resistance; hydraulic cylinders require larger diameters or higher pressure ratings.

Hydraulic System Upgrade: Requires higher-capacity hydraulic power units, higher-pressure-rated valves and piping, and larger accumulators to ensure rapid response and stable pressure holding under high loads.

Platen Design: Maintaining platen flatness and thermal efficiency under extreme pressure presents significant design challenges.

Control System Compatibility: Pressure sensors, control valves, etc., must be rated for higher ranges and precision requirements. Intelligent zonal pressure control becomes even more critical under high pressure to avoid local overloads.

Cost & Energy Impact: High-pressure customization entails higher equipment procurement costs and increased energy consumption (hydraulics, heating). A thorough cost-benefit analysis is essential, weighing the benefits (quality improvement, efficiency gains, raw material flexibility) against the increased costs.

✅ Intelligent Precision Control

Real-time sensor networks and AI algorithms enable multi-dimensional dynamic optimization of pressure, temperature, and speed.

Independent zonal pressure control (50+ pressure zones) compensates for material variations and ensures density uniformity.

Closed-loop process adjustment via online X-ray density profilers and thickness scanners.

✅ High-Pressure Customization Capability

Maximum working pressure exceeds 1000 bar (vs. 500-800 bar for standard presses).

Reinforced frame structure + high-pressure hydraulic system supports production of high-density boards (>800 kg/m³), ultra-thick panels, and hard raw materials.

Ensures process reliability for specialized applications (e.g., load-bearing structural boards, fire-resistant panel substrates).

✅ High-Efficiency Continuous Production

Continuous flat pressing increases output by 40%+ (vs. multi-opening presses).

Thickness tolerance ≤ ±0.15 mm; water absorption swelling reduced by 20%.

Cloud-based recipe management enables product specification changes in 10 seconds.

For more information, welcome contact us, we will reply you quickly and offer working videos with you

+86 18769900191, +86 15805496117, +86 18954906501

1. Particleboard:

1. Particleboard: