A complete veneer production line consists of the following core equipment working in tandem to process logs into dried veneer:

1. Log Handling Section

Log Unloader & Haul-In Machine: Automatically unloads logs from transport vehicles and conveys them orderly to the start of the production line.

Debarker: Efficiently removes bark and impurities from logs using a drum or cutterhead structure, protecting subsequent peeling tools and ensuring veneer smoothness.

Debarker: Efficiently removes bark and impurities from logs using a drum or cutterhead structure, protecting subsequent peeling tools and ensuring veneer smoothness.

2. Veneer Peeling Section

Veneer Lathe/Peeler: The core equipment of the line. It works by clamping a debarked block between a spindle and a tailstock, rotating it at high speed while a sharp blade feeds radially. This peels the block continuously like a pencil sharpener, producing a ribbon of veneer at a predetermined thickness. Precision spindles, drives, and controls determine thickness uniformity and surface quality.

3. Green Veneer Handling Section

Veneer Clipper: Located behind the lathe, it cuts the continuous veneer ribbon into rectangular sheets of preset length and width in real-time, automatically sorting out defective sections (e.g., large knots).

Veneer Conveyor & Stacker: Automatically conveys, aligns, and stacks the green (wet) veneer sheets into piles, preparing them for the dryer.

4. Veneer Drying Section

Roller Dryer or Mesh Belt Dryer: One of the most energy-intensive equipment. Green veneer is fed into the dryer where controlled high-temperature hot air circulates, reducing the moisture content from over 60% (fresh wood) to the required 8-12% for gluing, preventing mold.

5. Dry Veneer Handling Section

Veneer Splicer: Joins small dried veneer sheets or patched sheets into full-size sheets via scarfing, finger-jointing, or threading, greatly improving wood yield.

Veneer Patcher: Automatically detects defects like holes or splits in dry veneer and patches them with sound wood plugs, upgrading the veneer grade and value.

Veneer Grading & Stacking: Operators or automated systems grade the veneer by size, grade, and grain, then stack it for storage or transfer to the plywood production line.

Veneer Production Process Flow

Logs → Unloading/Haul-in → Debarking → Block Cutting (sawing to required length) → Soating/Steaming (softening wood for peeling) → Peeling → Clipping → Green Veneer Grading → Drying → Dry Veneer Patching/Splicing → Grading/Stacking → Packaging for storage or sending to the plywood mill.

What is Mixed Hardwood Raw Material?

"Mixed hardwood raw material" refers to the controlled and planned practice of processing logs from multiple hardwood species together.

Common Species Mix: May include Poplar, Eucalyptus, Birch, Okoume, Oak, Maple, etc. Often involves a scientific mix of fast-growing species (e.g., Poplar, Eucalyptus) and denser or more decorative species (e.g., Birch, Okoume).

Management: Although species are mixed, logs still need be sorted and process parameters adjusted based on diameter, hardness, and defects during production to ensure stable final veneer quality.

Advantages as Raw Material

1. Stable Supply Chain & Cost Reduction: Not reliant on a single species. Allows flexible procurement based on market prices and availability, mitigating raw material cost fluctuation risks.

2. Improved Resource Utilization: Makes full use of various wood resources, including fast-growing and plantation timber, reducing dependence on single precious species. Aligns with sustainable development.

3. High Flexibility: The production line's ability to handle multiple species allows companies to produce products with different styles and properties based on customer demand.

Advantages/Characteristics of Mixed Hardwood Veneer/Plywood

1. Performance Complementarity & Product Optimization:

Strength-Weight Balance: Using lighter woods (e.g., Poplar) for cores and stronger woods (e.g., Birch) for faces ensures overall strength while reducing weight.

Cost-Aesthetics Balance: Using lower-cost woods for core/back layers and decorative woods for the face layer controls costs while achieving an attractive appearance.

2. High Cost-Effectiveness: The core advantage. Mixed boards outperform those made solely from fast-growing species (e.g., all-Poplar) in performance and are far cheaper than boards made entirely from precious woods (e.g., all-Oak), making them highly competitive.

3. Structural Stability: Reasonable combination of woods with different shrinkage rates and the cross-graining craft results in plywood with excellent dimensional stability, resistant to warping and cracking.

1. Furniture Manufacturing: Used for furniture backs, sides, shelves, drawer bottoms (non-load-bearing parts), and frames/main structures of mid-range furniture.

2. Interior Decoration: Widely used for cabinets, wardrobes, partitions, wall panels, and ceilings.

3. Packaging Industry: Used for high-end export packaging cases and pallets requiring high strength and neat appearance.

4. Flooring Substrate: Used as the core substrate for engineered flooring, requiring high flatness and stability.

5. Other Industrial Uses: Interior panels for buses, shipbuilding, etc.

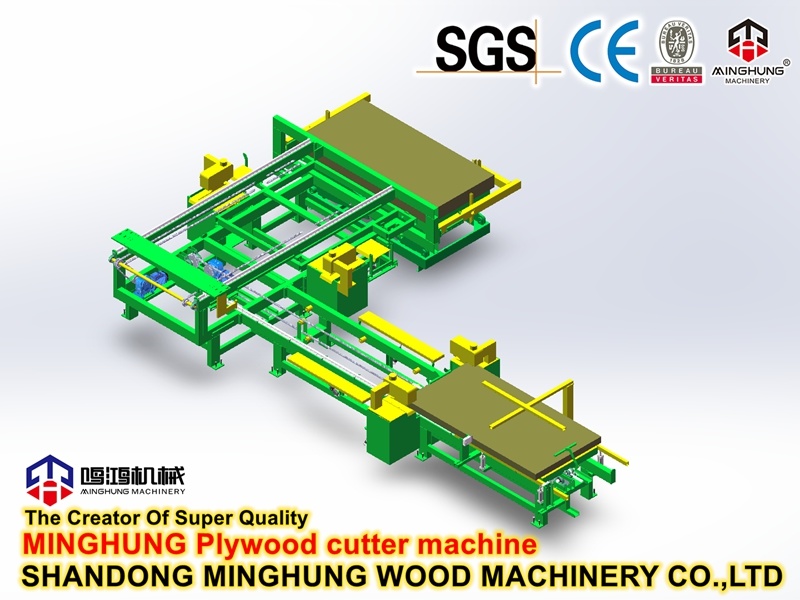

We are Shandong MINGHUNG Wood Based Panel Machinery Co.,Ltd,The mechanical equipment we produce includes:

Veneer production line(Log debaker,Veneer peeling machine, Log loader,Automatic stacker),Blade sharpener,Veneer patching machine,Veneer dryer machine(Veneer roller dryer, Veneer mesh dryer, Veneer press dryer), Veneer gluing machine,Plywood lay-up machine, Veneer jointing machine, Plywood cold press, Hot press machine,Plywood edge trimming cutting machine, Sanding and calibrating machine, Plywood overturn machine, Lift table, and so on.

We regularly participate in international industry exhibitions based on the company's business development and customer needs. On one hand, this helps us showcase our company's strength and expand new customers. On the other hand, we visit existing customers for follow-up visits, thereby enhancing the bond between them.

✅ Transform Your Production Now!

Request Your Customized Quote & Technical Proposal:

Call +86 18769900191, +86 15805496117, +86 18954906501 or 【Live Chat】

Get a productivity upgrade plan within 24h