Advantages of a Plywood Production Line

1. Exceptional Veneer Quality:

Consistent & Uniform Thickness: Dual-end rigid clamping and precise feed systems minimize vibration during peeling, producing veneer with very tight thickness tolerance, which is foundational for manufacturing high-grade, flat plywood.

Superior Surface Finish: Stable peeling reduces defects like "knife marks" or "fuzzing," resulting in veneer with lower backside checks and better strength.

2. High Production Efficiency & Automation:

High-Speed Peeling: Powerful dual-end drive allows higher rotational speeds, shortening veneer production cycles.

Handles Larger Logs: Can process larger diameter logs, broadening raw material sources and reducing cutting frequency.

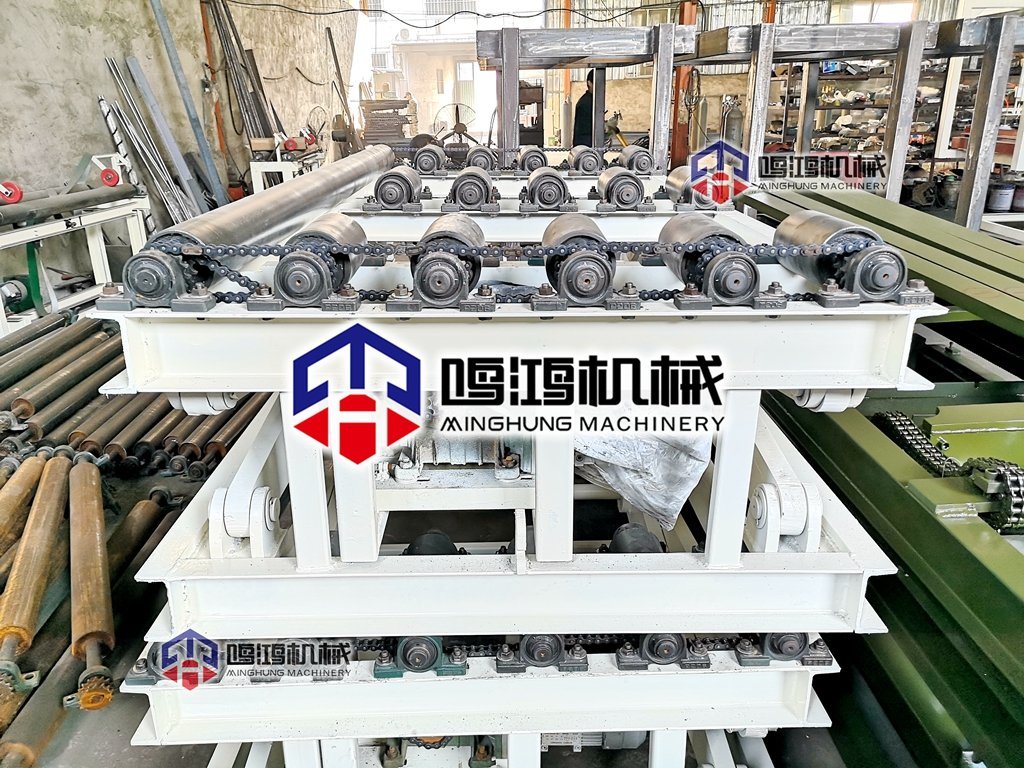

Enhanced Production Continuity: High reliability reduces downtime caused by machine faults or poor veneer quality, enabling smoother integration with downstream drying and layup lines.

3. High Raw Material Utilization (Yield):

Smaller Residual Core: Due to excellent clamping rigidity, peeling can continue to a much smaller core diameter (as low as ~Φ50mm), significantly increasing veneer yield per log and reducing wood cost.

4. Excellent Equipment Stability & Durability:

Balanced Load Distribution: The hydraulic system and dual-spindle design ensure even load distribution, reducing wear on key components like spindles and bearings, extending equipment lifespan, and lowering maintenance costs.

5. Significant Economic Benefits:

Combining the above advantages, although the initial investment for a hydraulic double-spindle peeler is higher than for traditional single-spindle machines, it substantially improves the overall profitability and competitiveness of the production line by enhancing veneer quality (enabling premium products), increasing yield (saving wood), boosting

productivity (higher output), and reducing waste.